3D Geomat for Erosion Control

Manufacturing Process

The production of 3D Geomat for erosion control follows controlled industrial processes:

Polymer raw material selection and blending with stabilizers

Extrusion of continuous filaments using multi-nozzle extrusion equipment

Random laying and spatial bonding to form 3D structure

Thermal welding or calendaring for dimensional stability

Online thickness and weight inspection

Roll cutting, packaging, and batch traceability labeling

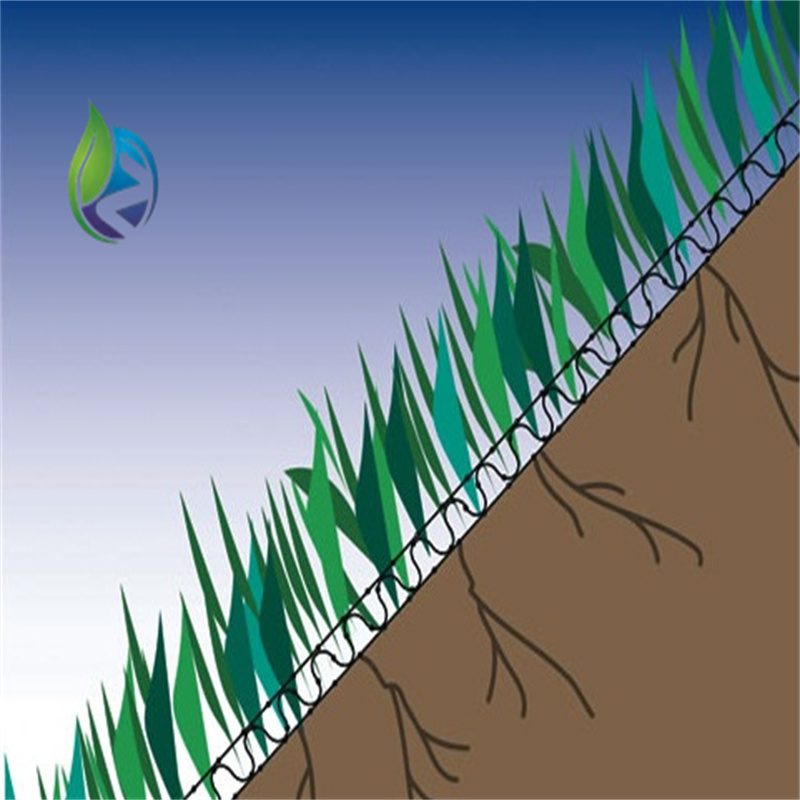

Product Definition

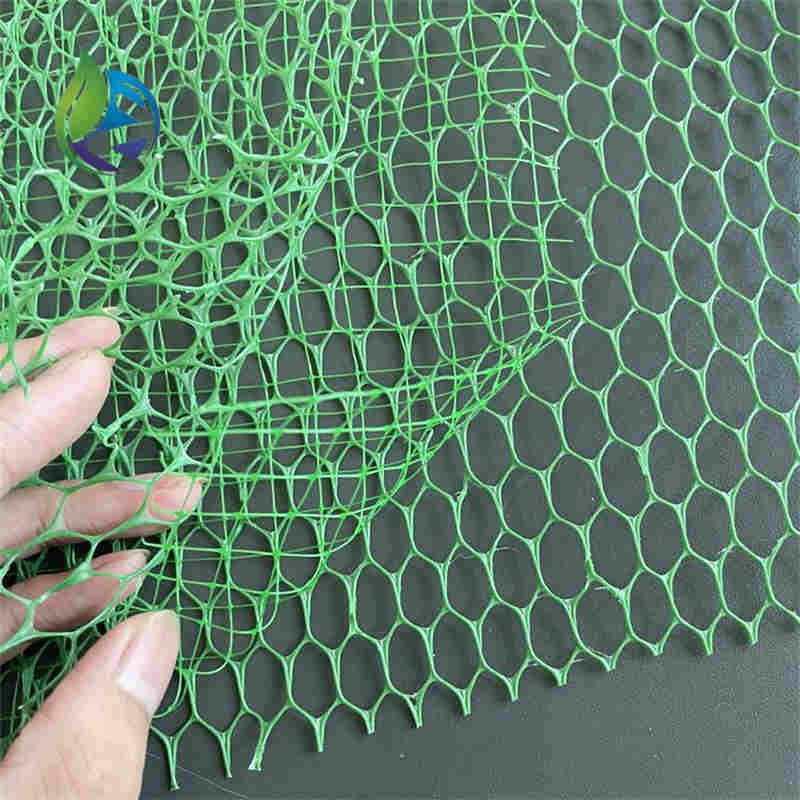

3D Geomat for erosion control is a three-dimensional synthetic polymer mat designed to stabilize soil surfaces, protect slopes from water and wind erosion, and promote vegetation growth by forming a permanent reinforcement layer.

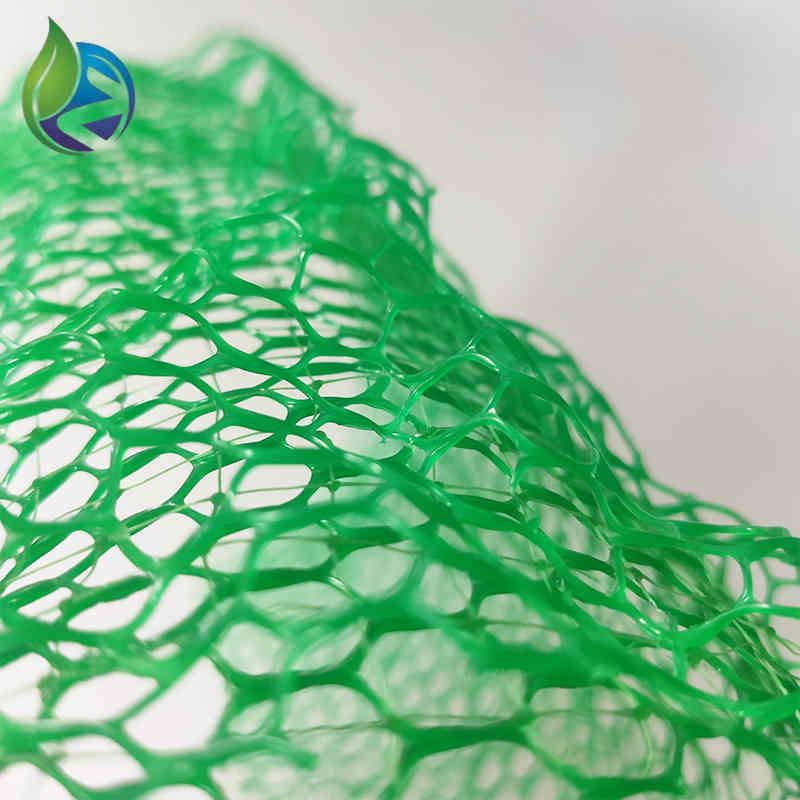

Technical Parameters and Specifications

The following specifications represent commonly adopted engineering-grade parameters for 3D Geomat systems:

Thickness: 10 mm – 20 mm

Unit weight: 250 g/m² – 500 g/m²

Material: UV-stabilized polypropylene (PP) or polyethylene (PE)

Tensile strength: ≥ 1.2 kN/m (MD/TD)

Elongation at break: ≥ 30%

Operating temperature range: -40°C to +80°C

Design service life: ≥ 20 years (soil-buried conditions)

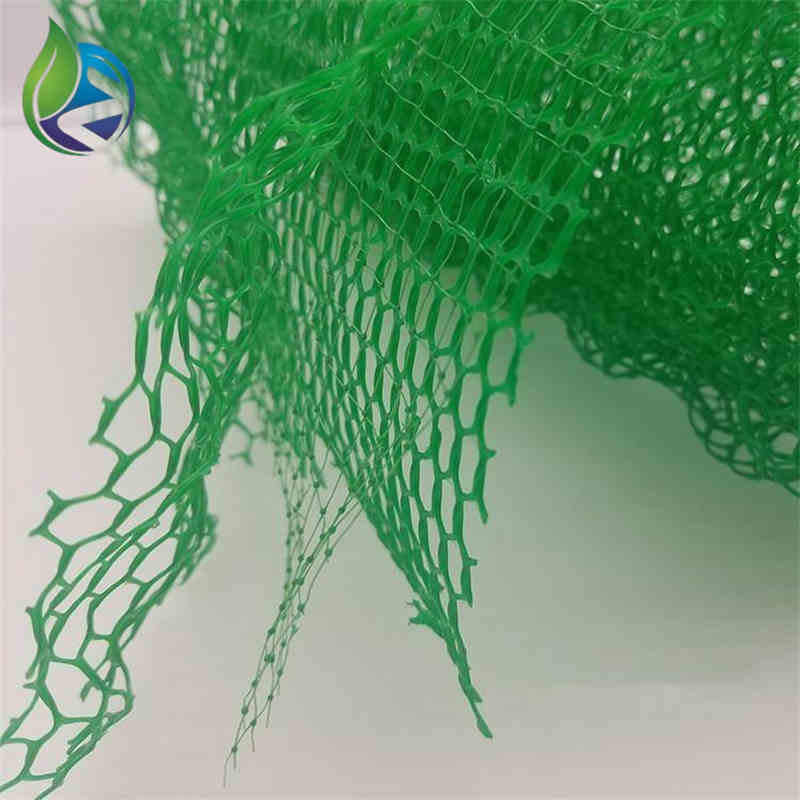

Structure and Material Composition

The performance of 3D Geomat for erosion control is driven by its engineered spatial structure:

Upper Layer: Randomly oriented polymer filaments forming surface protection

Middle Layer: Interlocked three-dimensional mesh providing soil anchorage

Bottom Layer: Open structure enabling root penetration and water infiltration

Material Additives: UV inhibitors, anti-aging stabilizers

Manufacturing Process

The production of 3D Geomat for erosion control follows controlled industrial processes:

Polymer raw material selection and blending with stabilizers

Extrusion of continuous filaments using multi-nozzle extrusion equipment

Random laying and spatial bonding to form 3D structure

Thermal welding or calendaring for dimensional stability

Online thickness and weight inspection

Roll cutting, packaging, and batch traceability labeling

Industry Comparison

| Material Type | Erosion Resistance | Vegetation Support | Service Life | Installation Complexity |

|---|---|---|---|---|

| 3D Geomat | High | Excellent | 20+ years | Moderate |

| Geotextile Fabric | Medium | Limited | 10–15 years | Low |

| Concrete Slope Protection | Very High | None | 30+ years | High |

| Natural Fiber Mat | Low | Good (short-term) | 1–3 years | Low |

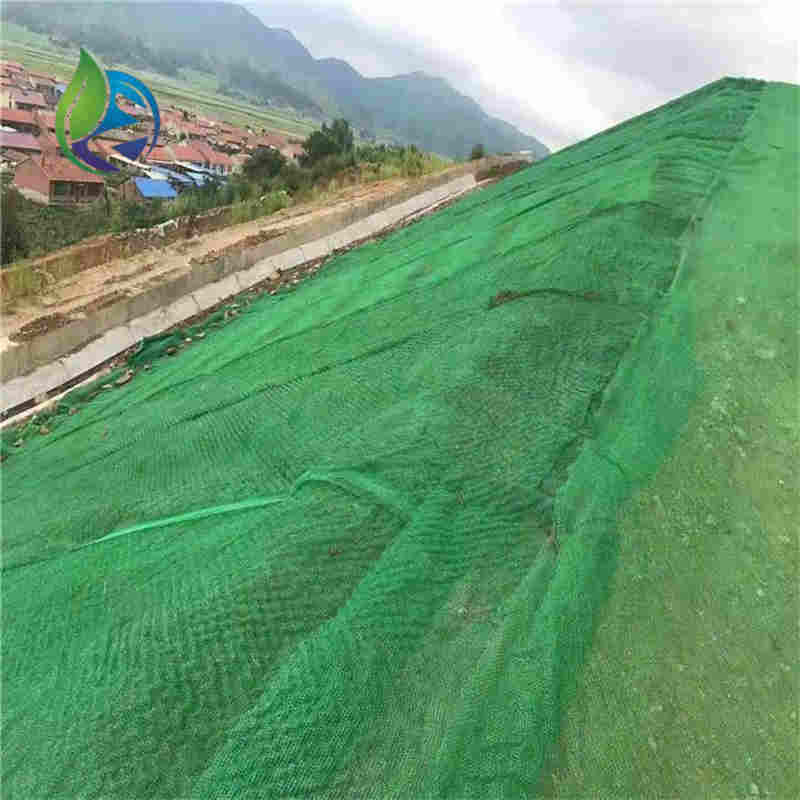

Application Scenarios

3D Geomat for erosion control is widely adopted by:

Highway and railway slope protection projects

Hydraulic engineering and riverbank stabilization

Mining rehabilitation and landfill capping

Municipal landscaping and green infrastructure

Industrial parks and EPC earthwork projects

Core Pain Points and Solutions

Pain Point: Soil loss on steep slopes

Solution: 3D structure provides mechanical anchoragePain Point: Poor vegetation survival

Solution: Open matrix retains moisture and seedsPain Point: UV degradation of materials

Solution: UV-stabilized polymersPain Point: High maintenance costs

Solution: Long service life with minimal intervention

Risk Warnings and Mitigation

Potential risks and corresponding mitigation measures include:

Improper anchoring: use specified steel or polymer anchors

Inadequate overlap: maintain ≥100 mm overlap between rolls

Exposure before backfilling: limit UV exposure during installation

Incorrect slope preparation: ensure compacted and graded subgrade

Procurement and Selection Guide

Define slope gradient and hydraulic conditions

Select appropriate thickness and unit weight

Verify polymer type and UV resistance

Check compliance with project specifications

Request laboratory test reports

Evaluate supplier manufacturing capability

Confirm logistics and roll dimensions

Engineering Case Study

In a highway slope stabilization project, 3D Geomat for erosion control with 15 mm thickness was installed on a 35° embankment slope. After hydroseeding and six months of growth, vegetation coverage exceeded 90%, with no visible soil erosion during seasonal rainfall.

FAQ

What is the main function of 3D Geomat? Soil stabilization and erosion prevention.

Can it be used underwater? Yes, with proper anchoring.

Is vegetation mandatory? Recommended for optimal performance.

Does it replace concrete? No, it is an ecological alternative.

What slopes are suitable? Typically up to 45°.

Is UV resistance required? Yes, for exposed conditions.

Can it be combined with geotextiles? Yes, in layered systems.

How is it installed? Anchoring + backfilling + seeding.

What is the roll width? Commonly 2–4 meters.

Is testing required before use? Recommended for major projects.

Call to Action

For project-specific pricing, technical datasheets, or engineering samples of 3D Geomat for erosion control, please submit your inquiry to our technical sales team.

E-E-A-T Author Statement

This article is prepared by a geosynthetics engineering team with over 15 years of experience in erosion control, slope stabilization, and infrastructure material selection for EPC and civil engineering projects worldwide.