Geomembrane Applied to Mines

Manufacturing Process

Geomembrane applied to mines is produced under strict industrial controls.

Polymer resin selection and batching

High-temperature extrusion or calendering

Sheet forming and thickness calibration

Surface texturing (if required)

Controlled cooling and stress relief

Online thickness and defect inspection

Roll cutting, labeling, and packaging

Product Definition: Geomembrane Applied to Mines

Geomembrane applied to mines refers to high-performance polymeric impermeable liners engineered for mining environments to control seepage, isolate contaminants, and ensure long-term environmental protection in tailings ponds, heap leach pads, waste rock facilities, and water management systems.

Technical Parameters and Specifications

Mining-grade geomembranes are manufactured to withstand chemical exposure, mechanical stress, and extreme climatic conditions.

Material types: HDPE, LLDPE, PVC, EPDM (project-specific)

Thickness range: 0.75 mm – 3.0 mm

Density (HDPE): ≥0.94 g/cm³

Tensile strength: ≥15 MPa (ASTM D6693)

Elongation at break: ≥700% (LLDPE)

Puncture resistance: ≥500 N

Carbon black content: 2.0–3.0%

Oxidative induction time (OIT): ≥100 min

Service life: ≥30–50 years (design condition)

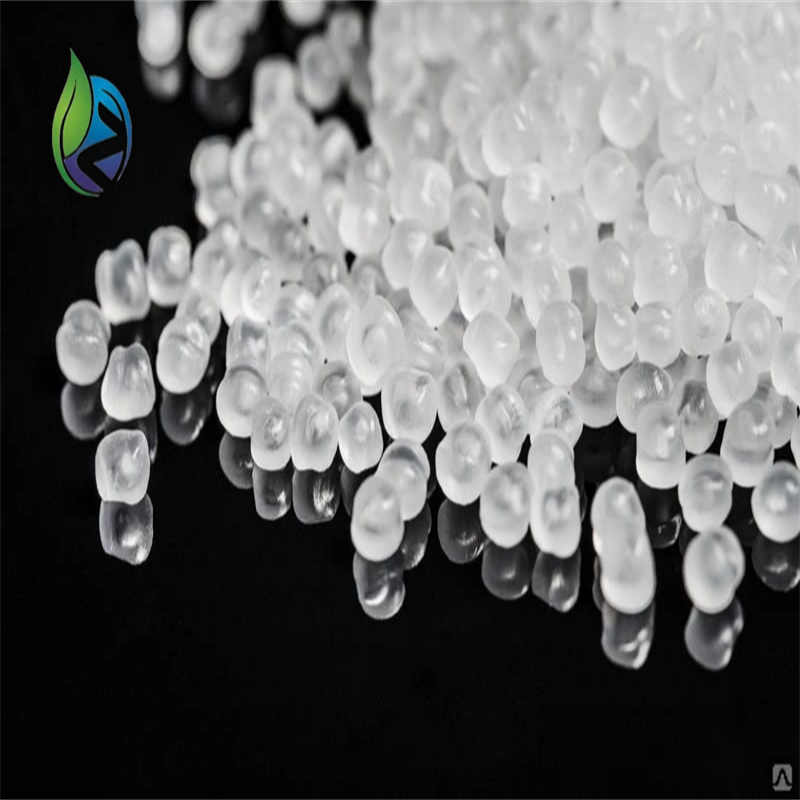

Structure and Material Composition

The structure of geomembrane applied to mines is optimized for durability and chemical resistance.

Primary Polymer Layer: High-purity polyethylene providing impermeability

Carbon Black Dispersion: UV resistance and aging protection

Stabilizer System: Antioxidants and thermal stabilizers

Optional Textured Surface: Improved interface friction on slopes

Manufacturing Process

Geomembrane applied to mines is produced under strict industrial controls.

Polymer resin selection and batching

High-temperature extrusion or calendering

Sheet forming and thickness calibration

Surface texturing (if required)

Controlled cooling and stress relief

Online thickness and defect inspection

Roll cutting, labeling, and packaging

Industry Comparison

| Liner Type | Chemical Resistance | Mechanical Strength | Installation Complexity | Mining Suitability |

|---|---|---|---|---|

| HDPE Geomembrane | Excellent | High | Medium | Very High |

| LLDPE Geomembrane | Very Good | Medium | Low | High |

| PVC Geomembrane | Moderate | Low | Low | Limited |

| Clay Liner | Low | Low | High | Low |

Application Scenarios in Mining

Geomembrane applied to mines is widely adopted in critical containment systems.

Heap leach pads for gold and copper mining

Tailings storage facilities (TSF)

Process water and pregnant solution ponds

Waste rock and overburden containment

Acid mine drainage control systems

Core Pain Points and Engineering Solutions

Chemical corrosion: Use HDPE with proven chemical compatibility testing

Slope instability: Apply textured geomembranes with geotextile interfaces

Seam leakage risk: Double-track hot wedge welding with NDT testing

Long-term aging: Specify high OIT and UV-stabilized formulations

Risk Warnings and Mitigation Advice

Mining projects involve high operational risks if liner systems are poorly designed.

Avoid underspecified thickness for high-load areas

Control subgrade preparation to prevent puncture

Implement strict welding quality control

Design leak detection systems for critical ponds

Procurement and Selection Guide

Define mining application and chemical exposure profile

Select geomembrane material type and thickness

Confirm compliance with ASTM / GRI standards

Evaluate supplier production capacity and QC systems

Request chemical resistance and aging test reports

Assess installation method and welding equipment

Plan logistics and roll size optimization

Engineering Application Case

In a copper heap leaching project covering 120,000 m², 2.0 mm textured HDPE geomembrane applied to mines was installed over a compacted clay subgrade. Double-liner configuration with leak detection reduced environmental risk and met regulatory approval requirements.

Frequently Asked Questions

Q1: Why is HDPE preferred in mining? A: Superior chemical and UV resistance.

Q2: What thickness is typical for tailings ponds? A: 1.5–2.5 mm.

Q3: Can geomembranes handle acidic solutions? A: Yes, with verified compatibility.

Q4: How are seams tested? A: Air pressure and vacuum box testing.

Q5: Is textured geomembrane mandatory on slopes? A: Recommended for stability.

Q6: What is the expected lifespan? A: 30–50 years under design conditions.

Q7: Can geomembranes be repaired on site? A: Yes, with extrusion welding.

Q8: Are multilayer systems required? A: Often for high-risk containment.

Q9: How is puncture resistance improved? A: Using protective geotextiles.

Q10: What standards apply? A: ASTM, GRI GM13/GM17.

Call to Action

For mining-grade geomembrane specifications, chemical compatibility data, project quotations, or engineering samples, procurement teams are invited to submit a formal technical inquiry.

E-E-A-T Author Credentials

This content is prepared by a geosynthetics engineering specialist with extensive experience in mining containment systems, supporting EPC contractors, mine owners, and international procurement teams on liner design and material selection.

Packaging: