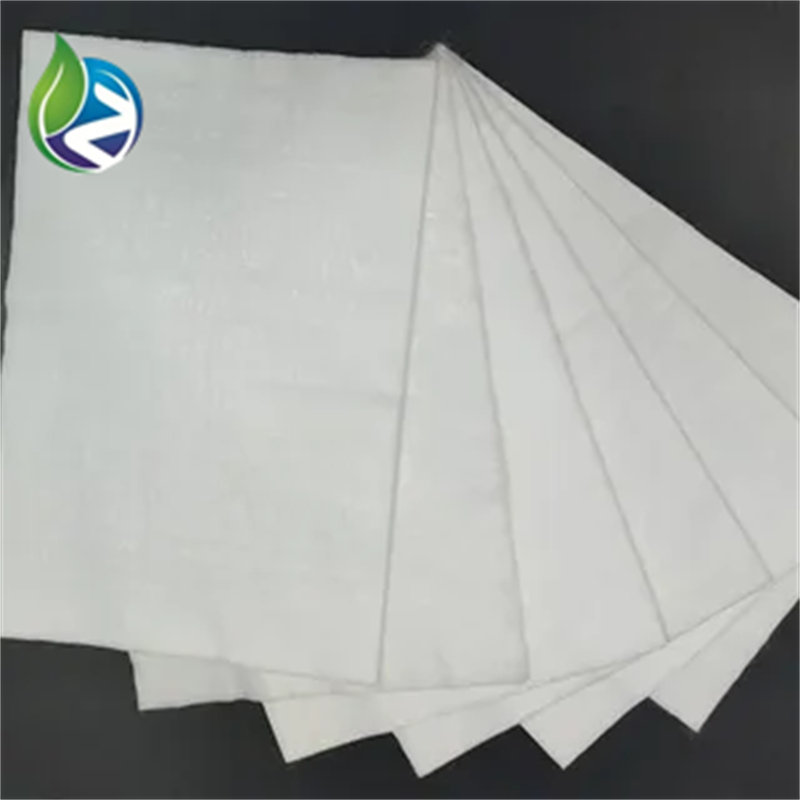

Nonwoven Geotextile Fabric

Filament spunbonded needled nonwoven geotextiles include staple fiber needled geotextiles and spunbonded filament geotextiles. It is processed by blending wool, fluxing, laying net, needling and multiple needling. It is characterized by high density, fluffy structure, corrosion resistance, aging resistance, acid and alkali resistance, good water absorption and water permeability, high tensile strength, and large deformation resistance. It is widely used in domestic engineering, such as preventing pavement turning, slope protection and canal protection layer.

In the world of civil engineering and environmental protection, few materials match the versatility and performance of the filament spunbonded nonwoven geotextile. Whether you're stabilizing roads, reinforcing slopes, or managing filtration in landfill projects, this advanced geosynthetic fabric is the gold standard for strength, permeability, and durability.

If you're planning a construction project that demands high-performance geotechnical solutions, investing in filament spunbonded nonwoven geotextile is a smart, long-term decision.

What Is Filament Spunbonded Nonwoven Geotextile?

Filament spunbonded nonwoven geotextile is a synthetic fabric made by bonding continuous polyester or polypropylene filaments into a robust, nonwoven sheet. The material is manufactured through a high-speed, thermal bonding process known as spunbonding. The result is a geotextile with uniform strength, high elongation, and excellent resistance to environmental degradation.

Key Features of Filament Spunbonded Nonwoven Geotextile

1. High Tensile Strength

The continuous filament structure of filament spunbonded nonwoven geotextile delivers unmatched tensile strength, making it ideal for reinforcement and load distribution in infrastructure and roadworks.

2. Excellent Filtration and Drainage

Its porous, nonwoven structure enables superior water permeability while blocking fine soil particles. This makes filament spunbonded nonwoven geotextile ideal for drainage and filtration applications in retaining walls, embankments, and landfills.

3. Outstanding Durability

With strong resistance to UV rays, chemicals, and biological degradation, filament spunbonded nonwoven geotextile ensures long-lasting performance, even in the most aggressive environments.

4. Flexibility and Ease of Installation

Despite its strength, the material is lightweight, flexible, and easy to cut or mold onsite, allowing for quick and efficient deployment across complex terrains.

Applications of Filament Spunbonded Nonwoven Geotextile

Road and Highway Construction: Reinforces subgrade, improves load-bearing capacity, and extends pavement life.

Railways: Prevents soil migration and maintains track stability.

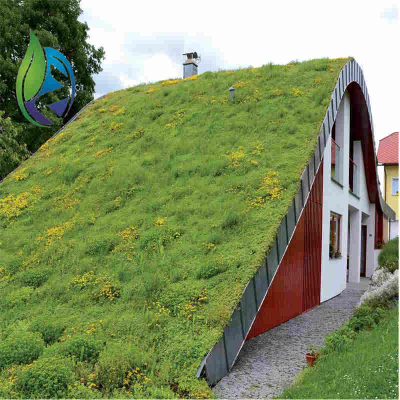

Retaining Walls and Slopes: Controls erosion and ensures slope reinforcement.

Drainage Systems: Provides long-term separation and filtration in subsurface drainage layers.

Landfills and Environmental Projects: Acts as a filtration and protection layer in waste containment systems.

No matter the complexity of the terrain or environmental conditions, filament spunbonded nonwoven geotextile offers reliable performance and longevity.

Why Choose Filament Spunbonded Nonwoven Geotextile?

When compared to woven geotextiles or short fiber alternatives, the filament spunbonded nonwoven geotextile excels in consistent tensile strength, filtration rate, and resistance to damage during installation. Its continuous filament design eliminates weak points and ensures uniform performance across the entire roll.

For high-load or critical engineering projects, filament spunbonded nonwoven geotextile is not just a material—it’s a strategic asset.

Installation Guidelines

Surface Preparation: Ensure the subgrade is smooth and free of sharp debris.

Roll Placement: Unroll the filament spunbonded nonwoven geotextile with minimal tension.

Seaming: Overlap edges as required, using adhesive or stitching if necessary.

Protection Layer: Apply the next construction layer (soil, aggregate, etc.) gently to prevent puncture.

Proper installation maximizes the functional lifespan of filament spunbonded nonwoven geotextile and ensures optimal project results.

Where to Buy Filament Spunbonded Nonwoven Geotextile

To get the best results, source your filament spunbonded nonwoven geotextile from experienced manufacturers or suppliers with technical certifications, customizable specifications, and strong post-sale support. Look for ISO-certified facilities and lab-tested performance data.

Conclusion

The filament spunbonded nonwoven geotextile has become a cornerstone of modern civil and environmental engineering thanks to its strength, stability, and versatility. Whether you’re reinforcing roads, filtering drainage layers, or protecting the environment, this advanced material delivers unmatched performance and durability.

For your next project, make a future-proof choice—invest in filament spunbonded nonwoven geotextile and build with confidence.

Applications:

1. The isolation layer between the road ballast and the roadbed, or the isolation layer between the roadbed and the soft foundation

2. Strengthen the flexible pavement, repair the cracks on the road, and prevent the pavement from reflecting cracks

3. For reinforcement in the backfill of retaining wall, or for anchoring the panel of retaining wall. Build a retaining wall or abutment.

4. Increase the stability of gravel slope and reinforced soil to prevent soil erosion and freezing damage at low temperature

5. Roads (including temporary roads), railways, embankments, earth-rock DAMS, airports, sports fields and other projects are used to strengthen weak foundations.