Grass Reinforcement Grids

Manufacturing Process

Raw Material Preparation: Virgin or recycled polymer pellet drying and filtration

Injection or Compression Molding: High-tonnage molding presses (800–1600 tons)

Cooling and Dimensional Stabilization: Controlled water and air cooling cycles

Edge Connector Forming: Precision forming of locking systems

Surface Texture Embossing: Mold-integrated surface roughness design

Quality Control: Load bearing, dimensional accuracy, and UV resistance testing

Packaging: Palletization and moisture-protected shrink wrapping

Product Definition

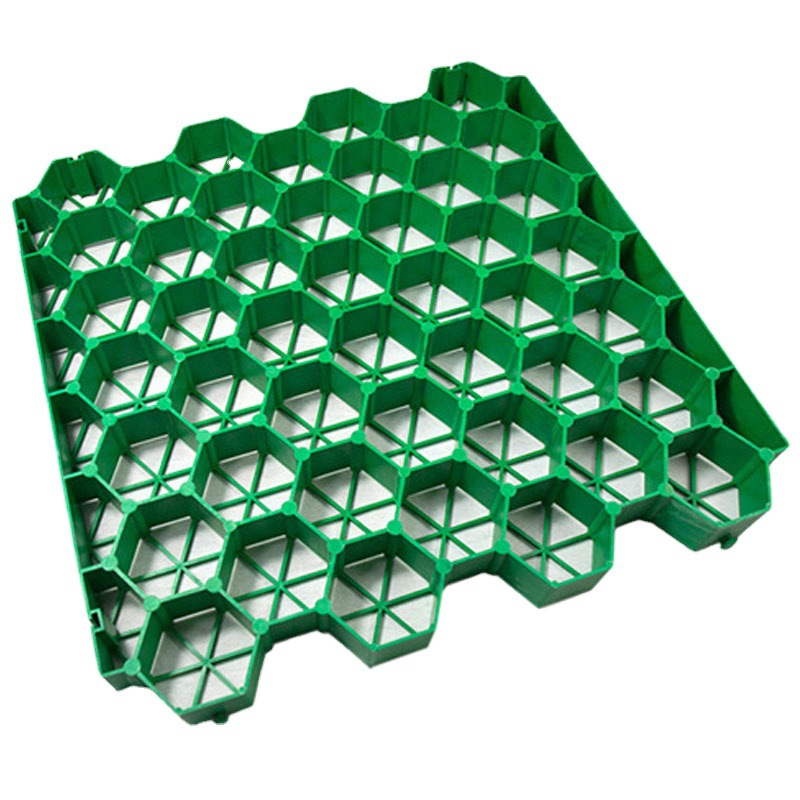

Grass Reinforcement Grids are load-bearing cellular pavement systems manufactured from polymer or concrete composites, designed to stabilize turf surfaces while distributing traffic loads, preventing soil compaction, and enabling sustainable permeable ground solutions for light to heavy vehicular use.

Technical Parameters and Specifications

Base Material: High Density Polyethylene (HDPE) or Recycled Polypropylene (PP)

Standard Panel Size: 500 mm × 500 mm

Cell Height: 30 mm, 40 mm, 50 mm

Wall Thickness: 3.5–5.0 mm

Compressive Strength: ≥ 160 kN/m² (filled condition)

Load Capacity: Up to 400 tons/m² (with concrete infill)

Open Area Ratio: 90–95% vegetation void space

Operating Temperature Range: –40°C to +80°C

UV Resistance: ≥ 3000 hours accelerated weathering

Permeability Rate: > 95% surface water infiltration

Structure and Material Composition

Top Load Distribution Ribs: Honeycomb cell framework

Interlocking Joints: Snap-fit or hook-lock edge connectors

Bottom Drainage Channels: Integrated water flow paths

Geotextile Layer (optional): Nonwoven separator underlayment

Surface Rib Texture: Anti-slip, root anchoring micro-texture

Manufacturing Process

Raw Material Preparation: Virgin or recycled polymer pellet drying and filtration

Injection or Compression Molding: High-tonnage molding presses (800–1600 tons)

Cooling and Dimensional Stabilization: Controlled water and air cooling cycles

Edge Connector Forming: Precision forming of locking systems

Surface Texture Embossing: Mold-integrated surface roughness design

Quality Control: Load bearing, dimensional accuracy, and UV resistance testing

Packaging: Palletization and moisture-protected shrink wrapping

Industry Comparison

| System Type | Load Bearing Capacity | Drainage Performance | Installation Speed | Maintenance Requirement |

|---|---|---|---|---|

| Grass Reinforcement Grids | High | Excellent | Fast | Low |

| Concrete Pavers | Very High | Low–Medium | Medium | Medium |

| Gravel Systems | Low–Medium | High | Fast | High |

Application Scenarios

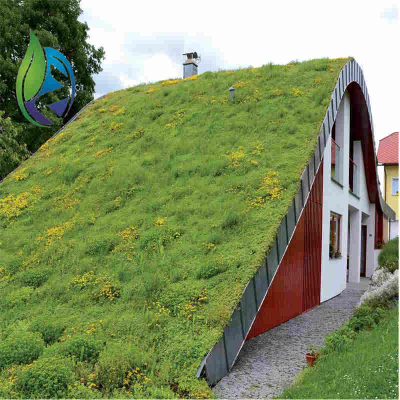

Emergency vehicle access routes

Parking lawns and overflow parking zones

Golf cart paths and resort landscaping

Fire lanes in commercial and residential developments

Slope stabilization and erosion control systems

Core Pain Points and Engineering Solutions

Soil Rutting Under Traffic: Cellular structure disperses wheel loads evenly

Poor Drainage and Waterlogging: High void ratio enables rapid infiltration

Vegetation Damage: Protective grid walls shield root zone from shear forces

Ground Settlement: Grid-reinforced layers reduce long-term deformation

Risk Warnings and Mitigation Recommendations

Risk: Inadequate subbase compaction

Mitigation: Minimum 95% Proctor density before grid placementRisk: Grid uplift during freeze-thaw cycles

Mitigation: Use geotextile separation and proper drainage layersRisk: UV degradation in storage

Mitigation: Store under UV-protective covers before installationRisk: Vegetation failure

Mitigation: Select grass species compatible with traffic load and climate

Procurement and Selection Guide

Define traffic load class and axle load requirements

Assess subgrade CBR value and moisture conditions

Select cell height based on design load and soil bearing capacity

Verify polymer grade and UV stabilization package

Request compressive and creep resistance test reports

Confirm interlocking compatibility for large-scale installation

Evaluate packaging efficiency for logistics and site handling

Engineering Application Case

In a municipal overflow parking project of 9,500 m², Grass Reinforcement Grids with 40 mm cell height were installed over a compacted crushed stone base. The system was designed for occasional heavy truck access. Post-installation monitoring over two rainy seasons showed stable load performance and consistent turf coverage without visible rutting.

FAQ

Q1: Are Grass Reinforcement Grids suitable for heavy trucks? A: Yes, when designed with adequate base layers.

Q2: Can they be used in cold climates? A: Yes, tested for freeze-thaw resistance.

Q3: Do they require concrete infill? A: Not mandatory; soil and grass fill are common.

Q4: What is the typical service life? A: 20–25 years under proper installation.

Q5: Can grids be cut on site? A: Yes, with standard power tools.

Q6: Are they recyclable? A: Yes, for polymer-based products.

Q7: How fast can installation be completed? A: Typically 200–400 m² per crew per day.

Q8: Do they affect natural drainage? A: They improve surface infiltration.

Q9: Is weed control required? A: Standard landscaping maintenance applies.

Q10: Can they be used on sloped surfaces? A: Yes, with anchoring and geotextile support.

Call to Action

For project-based quotations, detailed technical datasheets, or engineering samples of Grass Reinforcement Grids, submit loading conditions, project dimensions, and environmental data to the technical sales department.

E-E-A-T Author Credentials

This technical article is authored by a senior geotechnical engineer with over 15 years of experience in permeable pavement systems, soil stabilization technologies, and large-scale civil infrastructure design and implementation.