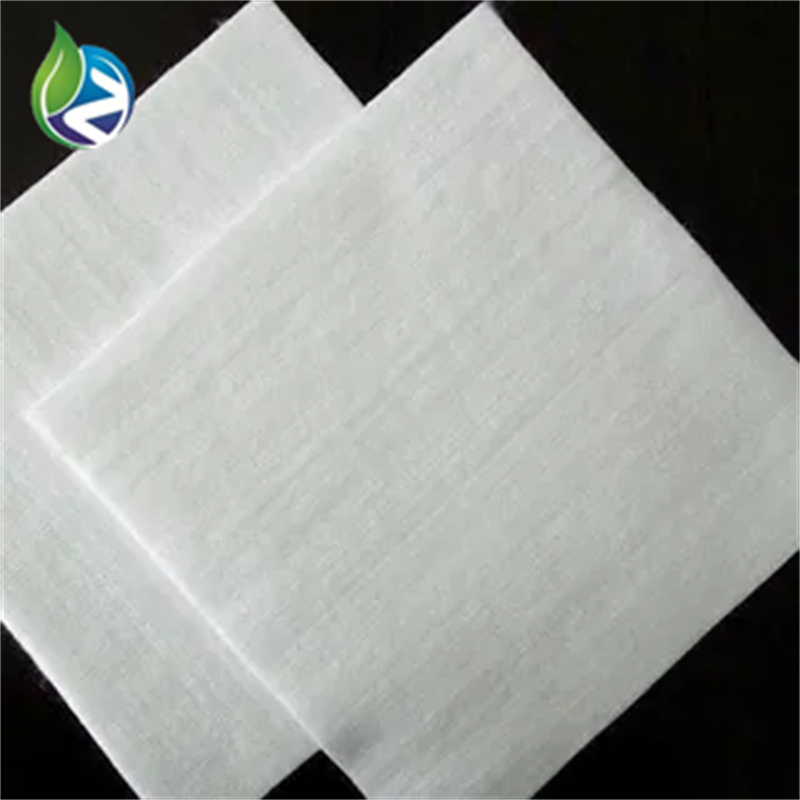

Staple fiber punched geotextile

Geotextile is a kind of nonwoven and industrial cloth. is the use of fiber density of 6-12 denier. length of 54-64mm polyester crimped staple fiber as raw materials through non-woven production equipment opening. combing. clutter (short fibers interwoven together). laying nets (standardized entanglement fixed). acupuncture and other production processes to make cloth. It is used in railway roadbed reinforcement. highway pavement maintenance. sports hall. dam protection. hydraulic construction isolation. tunnel. coastal beaches. reclamation. environmental protection and other projects.

In modern civil engineering, staple fiber punched geotextile has become a cornerstone material for geotechnical reinforcement, filtration, separation, drainage, and protection. Manufactured from high-quality polyester or polypropylene staple fibers, this nonwoven geotextile is mechanically bonded through needle punching, ensuring both strength and permeability.

Whether you're reinforcing road foundations, building embankments, or managing erosion control, staple fiber punched geotextile offers exceptional performance in even the harshest environments.

What is Staple Fiber Punched Geotextile?

Staple fiber punched geotextile is a type of nonwoven fabric made by mechanically entangling short fibers (staple fibers) using needle-punching technology. This process creates a dense yet flexible fabric that excels in filtration and separation tasks, allowing water to pass through while retaining soil particles.

Typically made from 100% virgin polyester or polypropylene, staple fiber punched geotextile is UV-resistant, chemically inert, and highly durable—ideal for both temporary and permanent civil works.

Key Features of Staple Fiber Punched Geotextile

✅ High Permeability & Filtration Capacity

Allows water flow while effectively retaining soil particles, preventing clogging and maintaining system functionality.

✅ Superior Strength and Puncture Resistance

The needle-punching process creates a robust structure that resists tearing and punctures, even under heavy loads.

✅ Excellent Soil Separation and Stabilization

Staple fiber punched geotextile prevents mixing of subgrade layers, increasing pavement lifespan and structural integrity.

✅ Eco-Friendly and Durable

Made from recyclable materials, it resists degradation from UV exposure, chemicals, and biological attack.

✅ Lightweight & Easy to Install

Supplied in rolls, it is simple to deploy and install with minimal labor and equipment requirements.

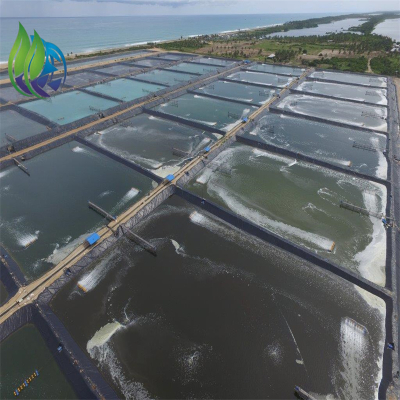

Applications of Staple Fiber Punched Geotextile

The versatility of staple fiber punched geotextile makes it essential in multiple geotechnical and environmental engineering fields:

? Road and Railway Subgrade Stabilization

? Retaining Wall Filtration and Drainage

? Erosion Control on Slopes and Embankments

? Asphalt Overlay Reinforcement

? Landfill Leachate Drainage Systems

? Agricultural and Landscaping Projects

? Coastal and Riverbank Protection

Wherever soil needs to be stabilized or filtered, staple fiber punched geotextile is a reliable, cost-effective solution.

Technical Specifications (Example Ranges)

| Property | Specification Range |

|---|---|

| Product Name | Staple Fiber Punched Geotextile |

| Material | PP or PET staple fiber |

| Weight | 100g/m² – 800g/m² |

| Thickness | 0.8mm – 6mm |

| Tensile Strength | Up to 25 kN/m |

| Elongation at Break | ≥ 40% |

| Water Permeability | ≥ 0.01 cm/s |

| Roll Width | 1m – 6m |

| Roll Length | 50m – 100m |

| Color | White, Grey, Black (customizable) |

| Manufacturing Process | Needle punched, thermally bonded (optional) |

Why Choose Staple Fiber Punched Geotextile?

Choosing a staple fiber punched geotextile ensures:

✅ Long-lasting performance under harsh conditions

✅ Enhanced filtration and drainage in geotechnical systems

✅ Cost-effective solution for large infrastructure projects

✅ Greater design flexibility for civil engineers and contractors

It’s widely used by professionals for its strength, simplicity, and environmental resilience.

Installation Guidelines

To maximize performance:

Site Preparation: Clear debris and level the surface.

Unrolling: Place the staple fiber punched geotextile with minimal wrinkles.

Overlap: Maintain a minimum overlap of 20–30cm between rolls.

Anchoring: Secure with pins or ballast as needed.

Backfill: Apply appropriate aggregate or fill on top and compact.

Proper installation ensures optimal filtration, separation, and durability over the structure’s lifespan.

Conclusion

For professionals seeking a high-strength, high-performance geotextile for filtration, separation, or erosion control, staple fiber punched geotextile stands out as the industry standard. Its combination of mechanical strength, permeability, and longevity makes it a go-to choice in civil, environmental, and geotechnical projects.

Partner With Us for Premium Staple Fiber Punched Geotextile Supply

We offer bulk manufacturing, OEM branding, technical consultation, and global delivery. Whether you’re bidding on large infrastructure projects or sourcing for municipal use, contact us today to request a free sample or technical datasheet of our staple fiber punched geotextile.

Key Features of Staple Fiber Punched Geotextile

High Strength and Durability

Staple fiber punched geotextiles are made from nonwoven synthetic fibers that are bonded together through a punching process, resulting in a fabric with high tensile strength and excellent durability. This strength ensures that the geotextile can withstand heavy loads and perform effectively in demanding construction environments. Its durability allows it to resist damage from environmental factors, such as UV exposure, moisture, and chemical degradation.Permeability and Filtration

One of the standout features of staple fiber punched geotextiles is their high permeability. The fabric allows water to flow through while retaining fine particles, which is essential for filtration applications. This ability to separate soil particles from water makes staple fiber geotextiles ideal for use in drainage systems, retaining walls, and road construction, where effective water drainage is critical.Excellent Erosion Control

The strong and durable nature of staple fiber punched geotextiles makes them an excellent choice for erosion control. These geotextiles can be placed on slopes, embankments, and other vulnerable surfaces to prevent soil erosion caused by wind or water. They effectively stabilize the soil, reduce surface runoff, and protect against landslides and soil displacement.Lightweight and Easy to Handle

Despite their strength, staple fiber punched geotextiles are lightweight and easy to handle. This makes them ideal for large-scale projects, as they can be easily transported, cut to size, and installed by hand or machine. The ease of handling reduces labor costs and speeds up installation, making it a cost-effective solution for construction projects.Eco-Friendly and Sustainable

Made from recyclable synthetic fibers, staple fiber punched geotextiles are an environmentally friendly option. They can be used in a variety of green construction practices, such as soil stabilization, water conservation, and erosion prevention, helping to promote sustainability in the construction industry.