Best Biaxial Plastic Geogrid

Manufacturing Process

Industrial production steps of Best Biaxial Plastic Geogrid:

Polymer drying and gravimetric batching system

Flat sheet extrusion using single-screw extruder

Precision punching to create regular aperture matrix

Sequential biaxial stretching in MD and CD directions

Heat setting to lock molecular orientation

Online tensile strength and junction integrity monitoring

Trimming, edge reinforcement, and surface stabilization

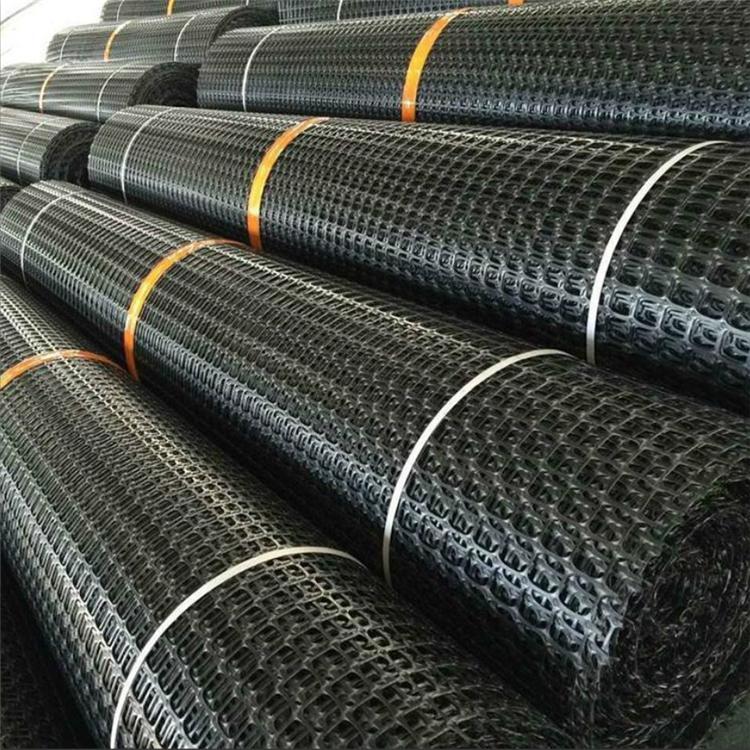

Automatic winding and roll packaging

Product Definition

Best Biaxial Plastic Geogrid is a biaxially oriented polymer grid engineered for soil reinforcement and load distribution in civil infrastructure. It improves bearing capacity, reduces differential settlement, and stabilizes pavement and foundation systems through mechanical interlock between aggregate and grid apertures.

Technical Parameters and Specifications

Standard engineering parameters for Best Biaxial Plastic Geogrid used in transportation and foundation works:

Raw material: Polypropylene (PP) or High-Density Polyethylene (HDPE)

Nominal tensile strength (MD/CD): 20–60 kN/m

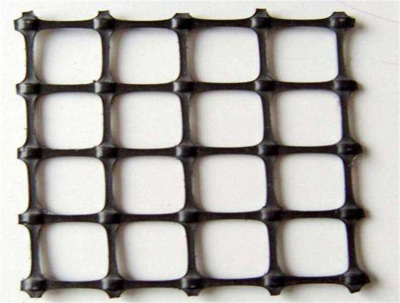

Aperture size: 30 × 30 mm to 65 × 65 mm

Junction efficiency: ≥90%

Ultimate elongation: ≤10%

Creep reduction factor: As per ISO 13431 long-term design

Roll width: 3.95 m – 5.20 m

Roll length: 50 m – 100 m

UV resistance retained strength: ≥70% after 500 h exposure

Structure and Material Composition

Engineering structure of Best Biaxial Plastic Geogrid:

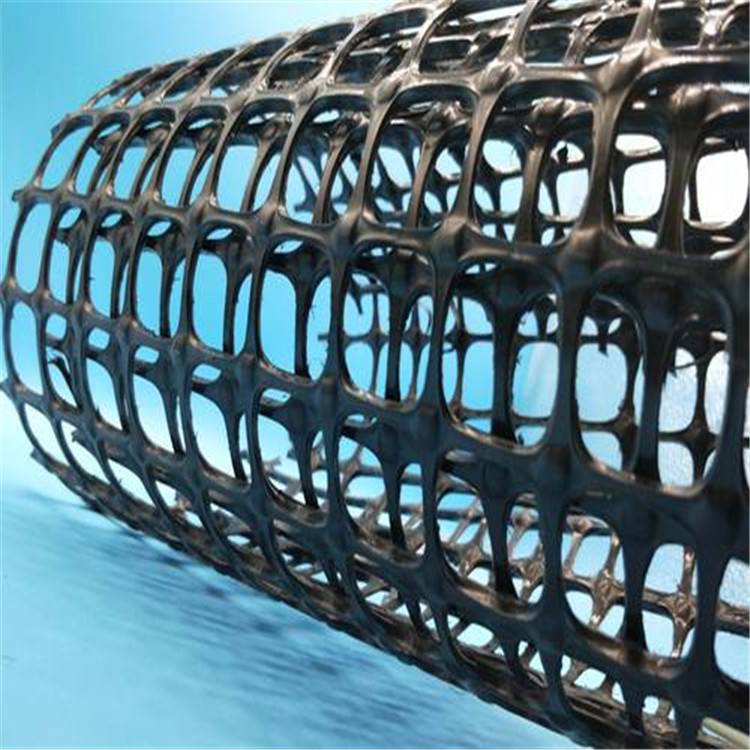

Integral punched sheet structure with uniform square apertures

Machine direction ribs (MD) for longitudinal load transfer

Cross-machine direction ribs (CD) for transverse reinforcement

Node junctions:

High-strength molecularly oriented joints

Optimized node thickness for shear resistance

Additive package:

Carbon black for UV resistance

Antioxidants for thermal stability

Manufacturing Process

Industrial production steps of Best Biaxial Plastic Geogrid:

Polymer drying and gravimetric batching system

Flat sheet extrusion using single-screw extruder

Precision punching to create regular aperture matrix

Sequential biaxial stretching in MD and CD directions

Heat setting to lock molecular orientation

Online tensile strength and junction integrity monitoring

Trimming, edge reinforcement, and surface stabilization

Automatic winding and roll packaging

Industry Comparison

| Reinforcement Material | Load Distribution | Installation Speed | Long-Term Creep | Typical Application |

|---|---|---|---|---|

| Best Biaxial Plastic Geogrid | Excellent | Fast | Very Low | Road base and subgrade |

| Woven Geotextile | Moderate | Fast | Moderate | Separation layers |

| Steel Mesh | Very High | Slow | None | Heavy load slabs |

| Natural Fiber Mat | Low | Fast | High | Temporary stabilization |

Application Scenarios

Typical application environments for Best Biaxial Plastic Geogrid across stakeholder groups:

Highway base and subbase reinforcement for EPC contractors

Industrial yard and port pavement stabilization for developers

Railway formation improvement for infrastructure companies

Airport runway subgrade reinforcement for civil contractors

Temporary and permanent access roads for mining projects

Core Pain Points and Engineering Solutions

Weak subgrade soils: Best Biaxial Plastic Geogrid increases bearing capacity through aggregate interlock.

Differential settlement: Biaxial structure distributes loads evenly in two principal directions.

Excessive rutting: Restrains lateral movement of aggregates, improving pavement life.

High maintenance cost: Extends service intervals and reduces repeated rehabilitation.

Risk Warnings and Mitigation Measures

Risk of insufficient overlap between rolls – maintain minimum 300 mm overlap.

Risk of UV exposure during storage – store under protective covers.

Risk of mechanical damage from sharp aggregates – inspect base course before placement.

Risk of improper tensioning during installation – apply manual pre-tensioning where specified.

Procurement and Selection Guide

Define project load class and traffic category.

Conduct subgrade CBR and modulus tests.

Select tensile strength grade based on design calculation.

Verify junction efficiency through certified lab reports.

Confirm roll dimensions for onsite handling capacity.

Request long-term creep data and reduction factors.

Check compliance with ASTM and ISO project standards.

Engineering Case Example

A logistics park development project installed Best Biaxial Plastic Geogrid over a 35,000 m² soft clay subgrade. The design incorporated 150 mm crushed stone base over the geogrid layer. Post-construction plate load tests indicated a bearing capacity increase of more than 40%, with reduced surface deformation under heavy axle loads.

FAQ

Q1: What is the primary function of Best Biaxial Plastic Geogrid?

A: Soil reinforcement and load distribution.

Q2: Can it be used in saturated soils?

A: Yes, with proper drainage design.

Q3: Does it replace geotextile?

A: No, it often works together as part of a composite system.

Q4: How long is the design service life?

A: Commonly 50 years in buried conditions.

Q5: Is special equipment required for installation?

A: No, standard earthwork equipment is sufficient.

Q6: What aperture size should be selected?

A: Based on aggregate gradation.

Q7: Can it be cut onsite?

A: Yes, using standard cutting tools.

Q8: How is quality verified?

A: Factory and third-party laboratory testing.

Q9: Is it resistant to chemical attack?

A: Yes, in typical soil and groundwater environments.

Q10: Which standards govern design?

A: ASTM, ISO, and national geotechnical standards.

Call to Action (CTA)

To request project pricing, detailed technical datasheets, or engineered samples of Best Biaxial Plastic Geogrid, submit a formal inquiry including load requirements, soil conditions, and applicable design standards. Technical support can assist with specification validation.

E-E-A-T Author Credentials

This technical content is prepared by a geotechnical engineer with over 15 years of experience in ground reinforcement systems, pavement engineering, and infrastructure projects, supporting EPC contractors, designers, and government agencies.