Flower-Shaped Plastic Grass Paver

Manufacturing Process

Flower-shaped plastic grass paver is produced using standardized industrial molding processes:

Polymer resin selection and compounding

Injection molding using precision steel molds

Controlled cooling and stress relief

Dimensional inspection and load testing

Edge trimming and surface finishing

Batch coding and traceability labeling

Palletizing and protective packaging

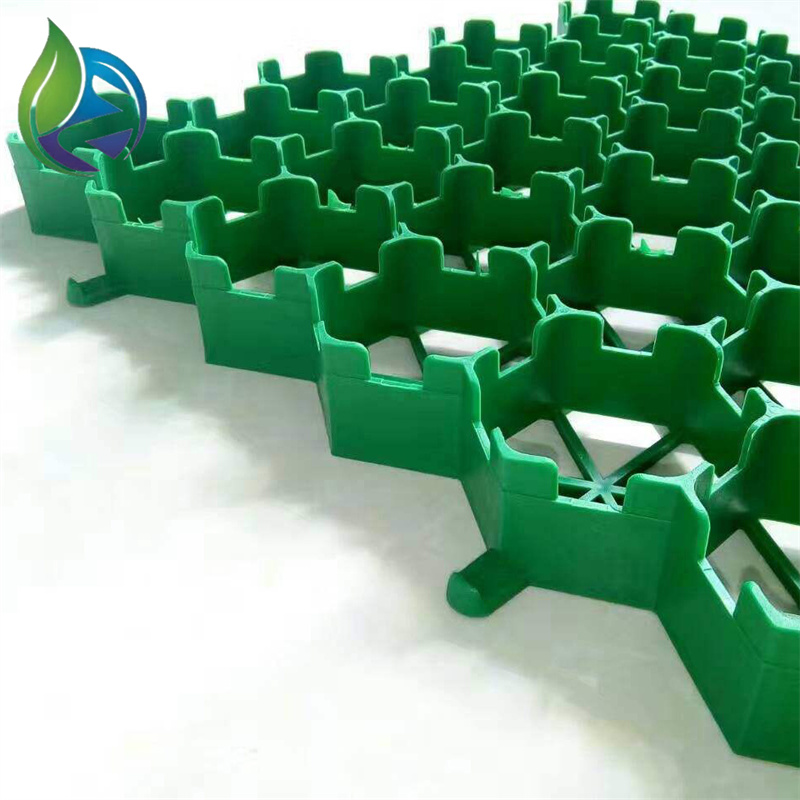

Product Definition

Flower-shaped plastic grass paver is a modular permeable ground reinforcement system made from high-strength polymer materials, designed to stabilize soil and turf surfaces while allowing vegetation growth and vehicular or pedestrian load distribution in green infrastructure projects.

Technical Parameters and Specifications

Typical engineering specifications for flower-shaped plastic grass paver include:

Material: HDPE or modified PP

Unit size: 380 × 380 mm or 400 × 400 mm

Thickness: 38 – 50 mm

Compressive strength: ≥ 200 t/m² (filled condition)

Void ratio: ≥ 85%

Water permeability: ≥ 10 mm/s

Operating temperature: -40°C to +80°C

Design service life: ≥ 20 years

Structure and Material Composition

The performance of flower-shaped plastic grass paver is determined by its engineered cellular structure:

Flower-Shaped Cell Walls: Radial geometry enhancing load dispersion

Interlocking Edges: Snap-fit or locking system ensuring lateral stability

Open Cell Cavities: High void ratio supporting grass root development

Base Support Feet: Even load transfer to subgrade layers

Polymer Additives: UV stabilizers and anti-aging modifiers

Manufacturing Process

Flower-shaped plastic grass paver is produced using standardized industrial molding processes:

Polymer resin selection and compounding

Injection molding using precision steel molds

Controlled cooling and stress relief

Dimensional inspection and load testing

Edge trimming and surface finishing

Batch coding and traceability labeling

Palletizing and protective packaging

Industry Comparison

| Ground System | Load Capacity | Permeability | Vegetation Support | Maintenance |

|---|---|---|---|---|

| Flower-Shaped Plastic Grass Paver | High | Excellent | Excellent | Low |

| Concrete Grass Grid | Very High | Medium | Good | Medium |

| Gravel Surface | Low | Good | Poor | High |

| Asphalt Pavement | Very High | None | None | Medium |

Application Scenarios

Flower-shaped plastic grass paver is widely specified in:

Landscape parking areas

Fire access roads and emergency lanes

Residential driveways

Municipal green infrastructure projects

Commercial plaza overflow parking

Industrial facility green zones

Core Pain Points and Solutions

Pain Point: Turf damage under vehicle load

Solution: High-strength flower-shaped load distribution cellsPain Point: Poor drainage causing muddy surfaces

Solution: High void ratio and vertical permeabilityPain Point: Surface rutting over time

Solution: Interlocking system preventing lateral movementPain Point: High maintenance costs

Solution: Durable polymer materials with long service life

Risk Warnings and Mitigation

Common risks and recommended mitigation measures include:

Insufficient subbase compaction: compact to ≥ 95% Proctor density

Improper infill material: use sand-soil or gravel-soil mix as specified

Edge restraint omission: install perimeter restraints

Early traffic loading: allow vegetation establishment before use

Procurement and Selection Guide

Confirm design load requirements

Evaluate site drainage conditions

Select appropriate paver thickness

Check material UV resistance certification

Review compressive strength test reports

Assess interlocking system performance

Verify supplier production capacity and quality control

Engineering Case Study

In a municipal parking project, flower-shaped plastic grass paver was installed over a compacted gravel subbase with sand-soil infill. After three years of mixed passenger vehicle use, no surface deformation was observed, and vegetation coverage remained above 90%.

FAQ

What loads can the paver support? Passenger vehicles and light commercial vehicles.

Is it suitable for fire lanes? Yes, when properly designed.

Can it be installed on slopes? Yes, with slope stabilization measures.

Does it require concrete? No, installed on granular subbase.

What infill is recommended? Sand-soil or gravel-soil mixtures.

Is it UV resistant? Yes, with stabilizer additives.

Can damaged units be replaced? Yes, modular replacement is possible.

Does it allow water infiltration? Yes, high permeability design.

What climates is it suitable for? Cold, temperate, and hot climates.

Is maintenance required? Minimal, mainly vegetation care.

Call to Action

For pricing, technical datasheets, load calculations, or project samples of flower-shaped plastic grass paver, please submit your project details to our technical sales team.

E-E-A-T Author Statement

This content is prepared by civil and landscape engineering professionals with over 15 years of experience in permeable pavement systems, green infrastructure design, and ground reinforcement technologies.