Road Reinforcement Geocell

Manufacturing Process

Material Selection: HDPE or PP is chosen for its high tensile strength, UV stability, and resistance to environmental wear.

Extrusion: The raw polymer is heated and extruded into sheets of the desired thickness.

Cell Formation: Sheets are thermoformed into the honeycomb cell structure using a specialized molding process.

Cell Expansion: The flat sheet is expanded to form the 3D honeycomb structure, making it transportable and easy to deploy in the field.

UV Stabilization: The final product undergoes UV treatment to ensure long-lasting performance under direct sunlight.

Cutting and Packaging: The geocells are cut to size and packaged for shipment.

Product Definition

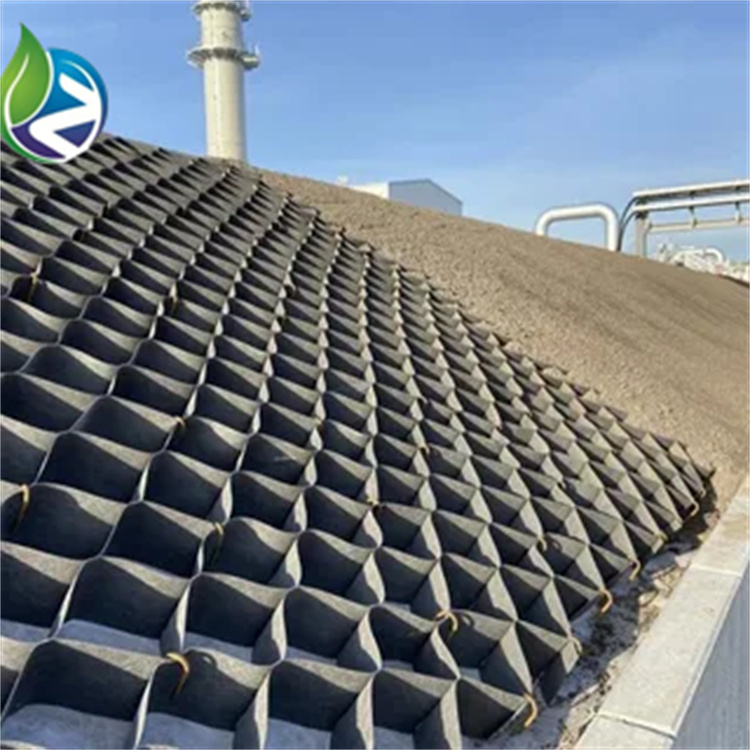

Road Reinforcement Geocell is a cellular confinement system designed to reinforce soils in road construction projects. Made from high-density polyethylene (HDPE) or similar polymers, these geocells provide stability, prevent soil erosion, and enhance load distribution for pavements, roads, and embankments. With a structure resembling a honeycomb, they offer an effective solution for improving the strength and longevity of road infrastructures.

Technical Parameters and Specifications

Material: High-density polyethylene (HDPE) or polypropylene (PP)

Cell Size: Typically 100mm x 100mm to 300mm x 300mm

Wall Thickness: 1.0mm to 2.5mm (depends on application load)

Expansion Ratio: 3:1 (allowing easy transportation and rapid deployment)

Tensile Strength: > 22 MPa

UV Resistance: UV stabilized for long-term outdoor use

Permeability: High permeability to allow water drainage

Load Distribution Capacity: Uniform distribution of pressure, improving road durability

Temperature Resistance: -40°C to 80°C

Warranty: 10–15 years depending on installation and environmental factors

Structure and Material Composition

The geocell structure consists of a series of interlocking cells that form a three-dimensional matrix. This structure is designed to confine granular infill materials such as gravel, sand, or crushed stone, thereby improving the overall bearing capacity and stability of road subgrades.

Top Layer: UV-resistant HDPE material with a honeycomb design that provides the primary reinforcement.

Core Structure: A matrix of interconnected cells, which allows for the confinement of granular materials, enhancing soil strength.

Base Layer: A non-woven geotextile layer may be added underneath to prevent soil erosion and increase drainage capacity.

Manufacturing Process

Material Selection: HDPE or PP is chosen for its high tensile strength, UV stability, and resistance to environmental wear.

Extrusion: The raw polymer is heated and extruded into sheets of the desired thickness.

Cell Formation: Sheets are thermoformed into the honeycomb cell structure using a specialized molding process.

Cell Expansion: The flat sheet is expanded to form the 3D honeycomb structure, making it transportable and easy to deploy in the field.

UV Stabilization: The final product undergoes UV treatment to ensure long-lasting performance under direct sunlight.

Cutting and Packaging: The geocells are cut to size and packaged for shipment.

Industry Comparison

| Material | Load Bearing Capacity | Water Drainage | Environmental Impact | Installation Time |

|---|---|---|---|---|

| Geocell (HDPE) | High, uniform distribution | High, promotes drainage | Low, recyclable | Fast, easy deployment |

| Traditional Asphalt | Moderate, localized | Low, prone to water pooling | High, non-recyclable | Moderate, requires curing time |

| Concrete Slabs | High, but prone to cracking | Low, needs proper drainage | High, energy-intensive | Slow, requires curing |

| Geogrid Reinforcement | Moderate, reinforced soil | Moderate, supports drainage | Moderate, less recyclable | Moderate, requires installation tools |

Application Scenarios

Road Subgrade Stabilization: Geocells are commonly used in constructing stable subgrades for highways, access roads, and temporary roads in construction sites.

Embankment Reinforcement: They enhance the structural integrity of embankments, preventing erosion and slope failures.

Drainage Improvement: Infill materials confined within geocells allow better water flow, reducing hydrostatic pressure and improving overall drainage.

Soil Erosion Control: Geocells prevent soil erosion in areas prone to heavy rainfall or high wind conditions.

Heavy Traffic Roads: Suitable for use in areas subject to heavy loads, such as industrial zones, ports, and logistic hubs.

Core Pain Points and Solutions

Poor Load Distribution: Geocells help in evenly distributing loads across large areas, reducing pressure on the road base and preventing damage.

Weak Soil Structure: Geocells reinforce weak soils, providing stability without the need for expensive soil replacement or treatment.

Waterlogging: High permeability allows geocells to prevent water accumulation, promoting proper drainage and reducing the risk of road subsidence.

Maintenance Costs: Geocells reduce long-term maintenance costs due to their durability and ability to withstand extreme weather conditions.

Risk Warnings and Mitigation

Improper Installation: If not installed correctly, geocells may fail to perform as expected, causing road subgrade issues. Ensure proper deployment and anchoring.

Incompatible Soil: The type of soil must be evaluated for suitability before using geocells. Certain soils may require additional geotextile layers.

Environmental Conditions: Extremely cold temperatures may affect the geocell's flexibility. Use with caution in freezing environments.

Infill Material Selection: The choice of fill material within the geocells affects overall performance. Ensure that materials like gravel or sand are well-graded and compacted.

Procurement and Selection Guide

Assess soil conditions and road traffic load requirements.

Select the appropriate cell size and wall thickness based on project specifications.

Confirm UV resistance and environmental certifications for long-term durability.

Review the supplier's quality control processes and manufacturing standards.

Request product samples for on-site testing and validation.

Consider transportation logistics and ease of installation.

Engineering Case Example

In a road project covering 10 km of urban arterial roads, geocells were used to reinforce the subgrade and prevent erosion along the embankments. The result was a cost-effective, long-lasting solution that supported heavy traffic loads while promoting sustainable drainage.

FAQ

How do geocells improve road stability? — Geocells confine granular material, providing better load distribution and preventing soil movement.

Can geocells be used on all soil types? — Geocells are most effective on weak soils; however, soil suitability should be evaluated before use.

What is the expected lifespan of geocells? — Geocells can last 10–15 years depending on environmental conditions and proper installation.

Are geocells affected by high temperatures? — Geocells are designed to perform within a temperature range of -40°C to 80°C.

Can geocells be used in wet conditions? — Yes, geocells help to improve drainage and prevent water accumulation.

What infill materials can be used? — Gravel, sand, crushed stone, or any granular materials can be used as infill.

What is the installation process like? — Geocells are expanded, placed in position, and filled with granular materials.

Can geocells be used in temporary roads? — Yes, geocells are ideal for temporary access roads and construction sites.

Are geocells easy to transport? — Yes, the 3:1 expansion ratio makes transportation simple and cost-effective.

How do geocells compare with traditional road materials? — Geocells offer a more cost-effective, sustainable, and easier-to-install solution compared to traditional asphalt or concrete.

Commercial CTA

If you are interested in receiving a quote, technical documentation, or project-specific samples of Road Reinforcement Geocells, please contact our team for further details.

E-E-A-T Author Credentials

This document has been authored by road construction engineers and geotechnical consultants with years of expertise in geocell technology, ensuring that all data and recommendations are accurate and relevant to industry standards.