Hdpe plastic dimple drain board

Manufacturing Process

HDPE resin drying and material conditioning

Extrusion through flat die sheet production line

Thermoforming of dimple structure using precision molds

Online thickness and geometry monitoring via laser systems

Thermal bonding of optional geotextile layers

Cooling and dimensional stabilization in controlled rollers

Automated cutting, winding, labeling, and pallet packaging

Product Definition

Hdpe plastic dimple drain board is an engineered drainage and protection panel manufactured from high-density polyethylene, designed to create continuous air and water flow channels, relieve hydrostatic pressure, and protect waterproofing membranes in foundation, tunnel, and structural underground engineering systems.

Technical Parameters and Specifications

Material: High-density polyethylene (HDPE)

Panel thickness: 0.8 mm – 2.0 mm

Dimple height: 8 mm – 20 mm

Compressive strength: ≥ 250 kN/m²

Void rate: ≥ 85%

Water flow capacity: ≥ 4.5 L/s·m

Temperature resistance: -30°C to +60°C

Chemical resistance: Resistant to common soil acids and alkalis

Standard roll width: 1.0 m – 3.0 m

Standard roll length: 10 m – 30 m

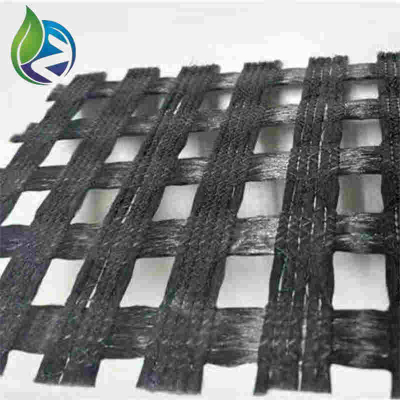

Structure and Material Composition

Top protective layer with organized dimple geometry

Core drainage channel structure formed by uniform studs

Base sheet layer for membrane protection

Optional laminated geotextile filter layer

Additive system:

UV stabilizers

Anti-aging antioxidants

Processing stabilizers

Manufacturing Process

HDPE resin drying and material conditioning

Extrusion through flat die sheet production line

Thermoforming of dimple structure using precision molds

Online thickness and geometry monitoring via laser systems

Thermal bonding of optional geotextile layers

Cooling and dimensional stabilization in controlled rollers

Automated cutting, winding, labeling, and pallet packaging

Industry Comparison

| Drainage Material | Load Capacity | Drainage Efficiency | Service Life | Installation Speed |

|---|---|---|---|---|

| Hdpe plastic dimple drain board | High | Excellent | 30–50 Years | Fast |

| Gravel Drainage Layer | Medium | Moderate | 10–20 Years | Slow |

| Concrete Drain Boards | Very High | Low | 40–60 Years | Slow |

| EPS Drainage Panels | Low | Moderate | 10–15 Years | Fast |

Application Scenarios

Basement and foundation wall drainage systems

Underground parking structure water management

Tunnel lining drainage and protection

Green roof and podium landscape drainage layers

Retaining wall back-drain systems for infrastructure projects

Key Pain Points and Solutions

Hydrostatic pressure buildup: High void ratio promotes continuous water discharge.

Membrane mechanical damage: Rigid HDPE sheet protects waterproof layers.

Drainage clogging: Optional geotextile prevents soil particle intrusion.

Difficult installation: Lightweight rolls reduce labor and equipment demand.

Risk Warnings and Mitigation Recommendations

Substrate must be cleaned of sharp protrusions before placement.

Edge overlap and fastening points must be secured against soil ingress.

Avoid prolonged UV exposure without temporary covering.

Verify compatibility with specified waterproofing membranes.

Procurement and Selection Guide

Define load requirements based on soil depth and structural backfill calculations.

Select appropriate dimple height according to required drainage volume.

Confirm compressive strength with certified laboratory reports.

Choose laminated geotextile option for fine soil environments.

Evaluate roll dimensions for site logistics and handling efficiency.

Verify production capacity and quality control systems of manufacturer.

Request project-specific drawings and installation guidelines.

Engineering Case Example

In a commercial underground parking project, hdpe plastic dimple drain board was installed along 3,500 square meters of retaining wall surface. A laminated geotextile layer was applied to prevent silt blockage. Field inspections confirmed stable water discharge, and post-construction moisture monitoring showed effective pressure relief and dry interior wall conditions.

FAQ

Q1: What is the typical lifespan?

A: 30–50 years under standard burial conditions.Q2: Can it be installed vertically?

A: Yes, it is suitable for vertical and horizontal drainage.Q3: Does it replace gravel drainage?

A: In many designs, it can reduce or eliminate gravel layers.Q4: What is the standard overlap width?

A: Typically 100–150 mm.Q5: Is it resistant to soil chemicals?

A: Yes, HDPE resists common soil-based acids and alkalis.Q6: Can it be cut on site?

A: Yes, using standard construction cutting tools.Q7: Is geotextile mandatory?

A: Recommended for fine-grained or silty soil conditions.Q8: What backfill is suitable?

A: Free-draining granular backfill is recommended when specified.Q9: Does it need special fixings?

A: Mechanical anchors or compatible adhesives are commonly used.Q10: How is quality verified on site?

A: Visual inspection and flow testing are standard practices.

CTA

For formal quotations, detailed technical datasheets, or project samples of hdpe plastic dimple drain board, provide your structural drawings and drainage design requirements for professional engineering review.

E-E-A-T Author Credentials

This article is prepared by a civil infrastructure materials specialist with over 15 years of experience in foundation drainage engineering, geosynthetics design, and EPC technical support for large-scale construction projects.

You have not enough Humanizer words left. Upgrade your Surfer plan.