Geomembrane Composite Sandwich

Manufacturing Process

The production of Geomembrane Composite Sandwich involves several critical steps:

Material Selection: High-quality geomembrane and durable support materials are selected based on project requirements.

Extrusion and Bonding: The geomembrane is extruded and bonded to the support layers using heat lamination or adhesive processes.

Perforation (Optional): Some products include perforated designs for better drainage or filtering properties.

Cutting and Shaping: The composite sandwich material is cut into specific roll sizes or sheets.

Quality Control: The product undergoes a series of tests, including waterproofing, tensile strength, and environmental resistance tests.

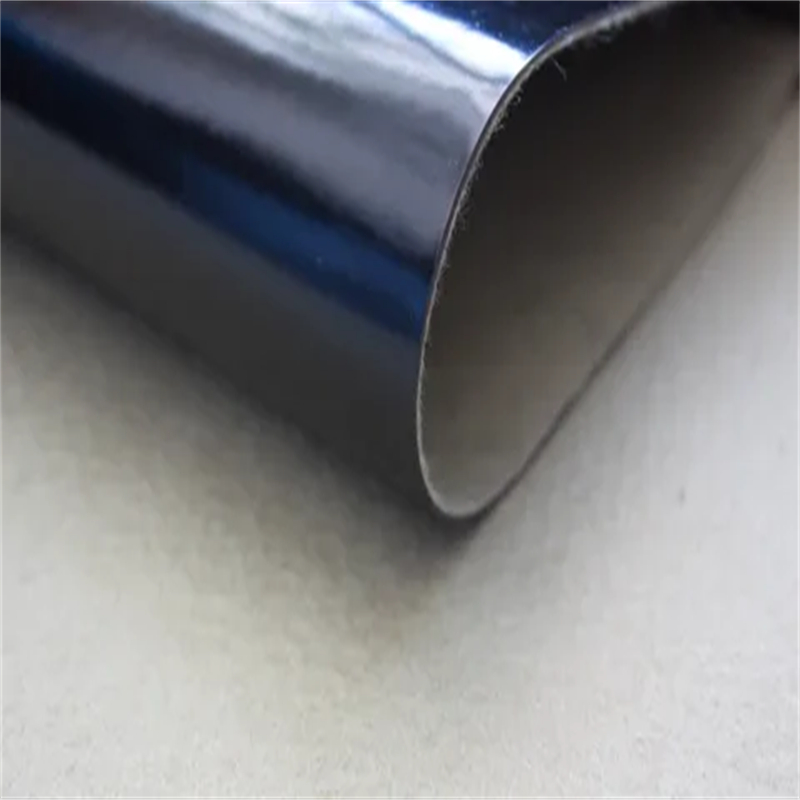

Product Definition

The Geomembrane Composite Sandwich is an advanced engineering material consisting of a geomembrane layer bonded between two other protective layers. This composite structure is designed for applications requiring superior waterproofing, chemical resistance, and durability in harsh environmental conditions, often used in landfills, dams, and wastewater treatment facilities.

Technical Parameters and Specifications

| Parameter | Specification |

|---|---|

| Thickness | 1–5 mm |

| Compressive Strength | ≥ 250 kPa |

| Flexural Strength | ≥ 500 kPa |

| Tensile Strength | ≥ 25 MPa |

| Waterproofing Performance | ≥ 1.0 x 10-13 m/s |

| Temperature Resistance | -40°C to 80°C |

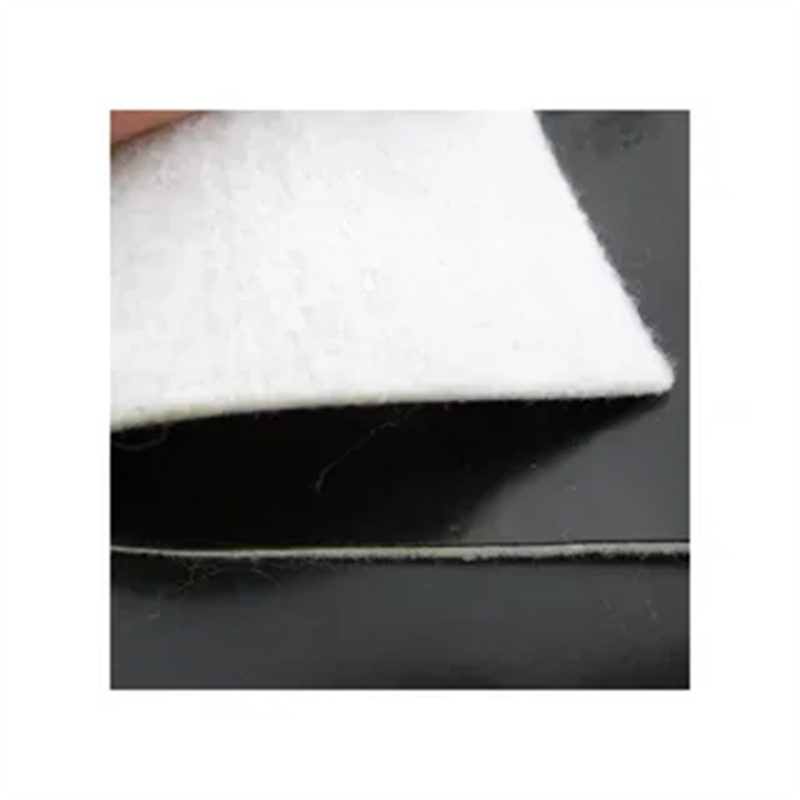

Structure and Material Composition

The Geomembrane Composite Sandwich typically consists of three key layers:

Geomembrane Layer: A flexible polymer material such as HDPE (High-Density Polyethylene), providing primary waterproofing and chemical resistance.

Support Layer: Non-woven geotextile or another support material bonded to the geomembrane to enhance durability and prevent puncturing.

Protective Outer Layer: Another geotextile or synthetic material that protects the geomembrane and improves soil interaction, ensuring stability under pressure.

Industry Comparison

| Material | Geomembrane Composite Sandwich | Traditional Geomembrane | Geotextile Fabric |

|---|---|---|---|

| Tensile Strength | High (≥ 25 MPa) | Moderate | Low |

| Waterproofing Performance | High (≥ 1.0 x 10-13 m/s) | Moderate | None |

| Durability | High (chemical, UV resistant) | Moderate | Low |

| Installation | Easy (roll or sheet) | Moderate | Simple but less effective alone |

Applications

Geomembrane Composite Sandwich is highly versatile and suitable for various industrial applications, including:

Landfills: Used to prevent leakage and contamination of groundwater.

Dams and Reservoirs: Provides waterproofing and soil protection against erosion.

Wastewater Treatment: Utilized to line treatment ponds and lagoons to ensure proper containment.

Mining Operations: Applied in heap leach pads for efficient water and chemical management.

Core Pain Points and Solutions

Pain Point: Leakage and groundwater contamination in landfills.

Solution: Geomembrane composite sandwich provides high waterproofing performance, preventing any leakage.

Pain Point: Material degradation due to UV exposure and harsh chemicals.

Solution: The composite structure offers excellent UV and chemical resistance, ensuring long-term durability.

Pain Point: High installation and maintenance costs.

Solution: Simple installation methods, coupled with low-maintenance requirements, reduce overall project costs.

Pain Point: Poor drainage in certain applications.

Solution: Perforated versions of the composite sandwich enhance drainage in areas with excess water buildup.

Risk Warnings and Precautionary Advice

While the geomembrane composite sandwich is highly effective, there are a few risks to consider:

Improper Installation: Ensure that the material is installed correctly to avoid leaks and other failures.

Chemical Exposure: Certain chemicals may degrade materials, so ensure compatibility before use.

UV Exposure: Extended UV exposure may reduce the longevity of materials; consider UV-protected layers for long-term use.

Procurement and Selection Guide

Follow these steps to select the ideal geomembrane composite sandwich for your project:

Identify the environmental conditions (temperature, chemical exposure, UV exposure).

Determine the required tensile and compressive strength based on the project's load-bearing needs.

Assess waterproofing needs and confirm performance requirements (e.g., leakage prevention).

Ensure the material is compatible with other construction systems in place (e.g., drainage systems).

Evaluate the ease of installation and long-term maintenance costs.

Consult with suppliers to confirm compliance with industry standards and regulations.

Case Studies and Real-World Applications

Below is a real-world application of the Geomembrane Composite Sandwich in a large construction project:

Project: Wastewater Treatment Facility Lining

Location: Industrial Zone, Heavy Chemical Exposure

Challenge: Prevent leakage and chemical contamination from wastewater.

Solution: The geomembrane composite sandwich was installed as the primary lining material, offering superior waterproofing and chemical resistance.

Result: The facility successfully contained wastewater without contamination, ensuring compliance with environmental regulations.

FAQ

What is the lifespan of a geomembrane composite sandwich? Typically, 25-30 years when properly installed and maintained.

Can it be used in high-temperature environments? Yes, it can withstand temperatures from -40°C to 80°C.

Is the geomembrane composite sandwich suitable for mining applications? Yes, it is widely used in mining operations, especially for heap leach pads.

Can the material be perforated? Yes, perforated versions are available for applications requiring drainage.

Is installation complicated? No, the material is easy to install in rolls or sheets.

How resistant is the material to chemicals? It has excellent resistance to most chemicals, making it ideal for wastewater and landfill applications.

Is the material environmentally friendly? Yes, it is designed to prevent contamination and promote sustainability.

Can geomembrane composite sandwich be recycled? Yes, the material is recyclable after use.

How does it compare to traditional geomembranes? It offers better durability and additional protective layers, improving performance.

Can it be used for dam construction? Yes, it is commonly used in dams for waterproofing and protection against erosion.

Request a Quote

If you are interested in purchasing the Geomembrane Composite Sandwich or require further technical details, please contact us for a detailed quote, technical documentation, or engineering samples.