Warp Knitting Polyester Geogrid

Polyester biaxial geogrid is a high-strength, lightweight, and durable reinforcement material commonly used in civil engineering applications. It is a woven or knitted fabric made from high-tenacity polyester yarns, arranged in two perpendicular directions to provide bidirectional reinforcement. This unique structure allows the geogrid to distribute and withstand tensile and shear forces effectively, enhancing the overall stability and load-bearing capacity of soil, pavement, and retaining structures. Its resistance to chemical degradation, UV radiation, and temperature fluctuations makes it an ideal choice for a wide range of projects, from road construction and slope stabilization to soil reinforcement and embankment reinforcement.

Warp Knitting Polyester Geogrid for Road & Highway Construction

Warp knitting polyester geogrid for road & highway construction is an advanced geosynthetic material designed to reinforce soil, improve load-bearing capacity, and extend the lifespan of pavements. With its unique high-strength structure and exceptional durability, warp knitting polyester geogrid for road & highway construction is widely used in civil engineering, particularly for base stabilization, subgrade reinforcement, and minimizing deformation under heavy traffic.

Choosing warp knitting polyester geogrid for road & highway construction enhances project efficiency, reduces maintenance costs, and supports sustainable infrastructure development.

What Is Warp Knitting Polyester Geogrid?

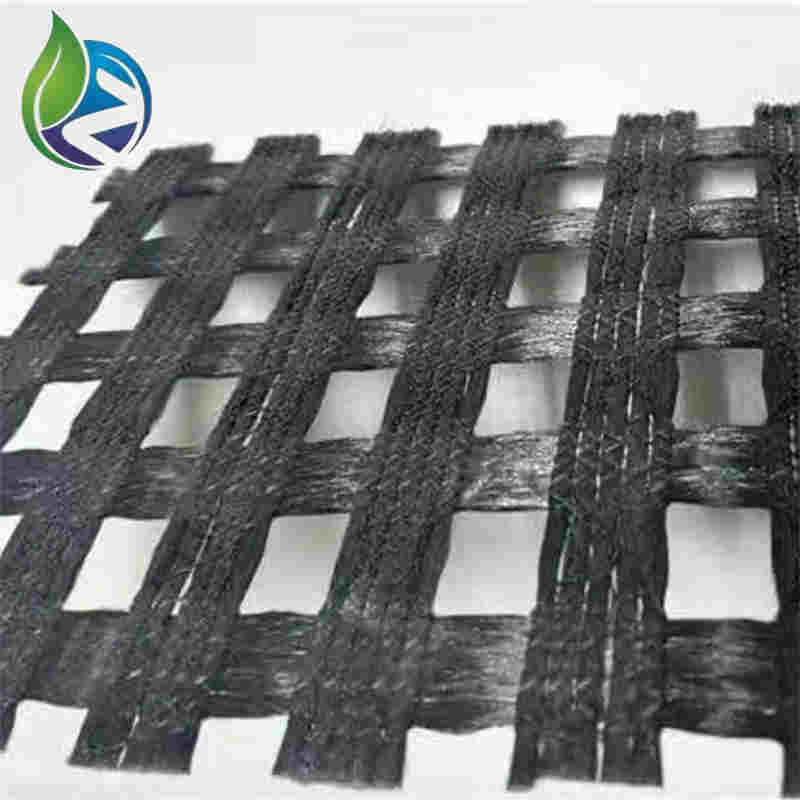

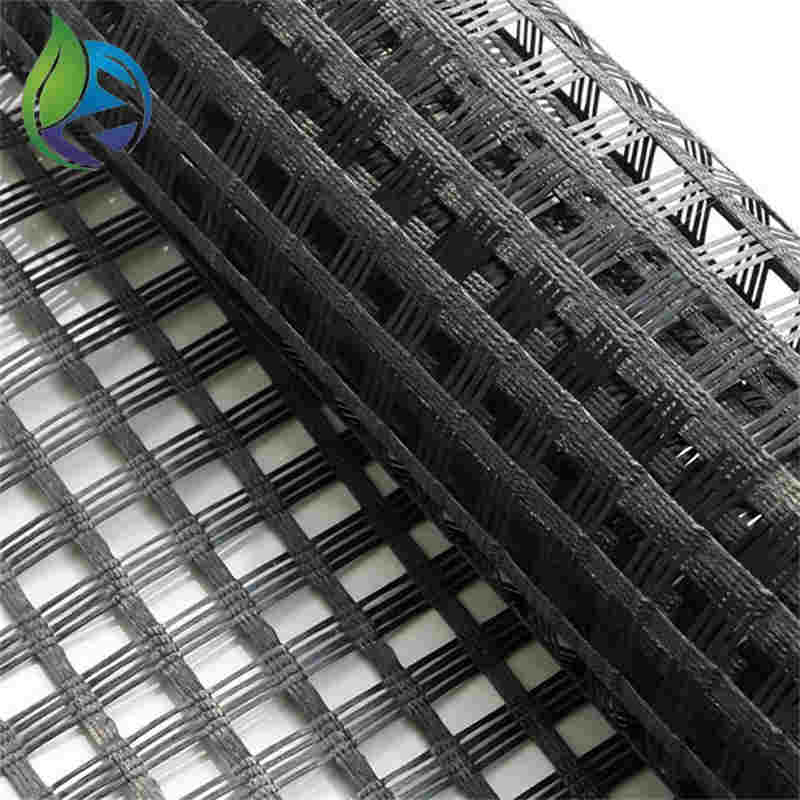

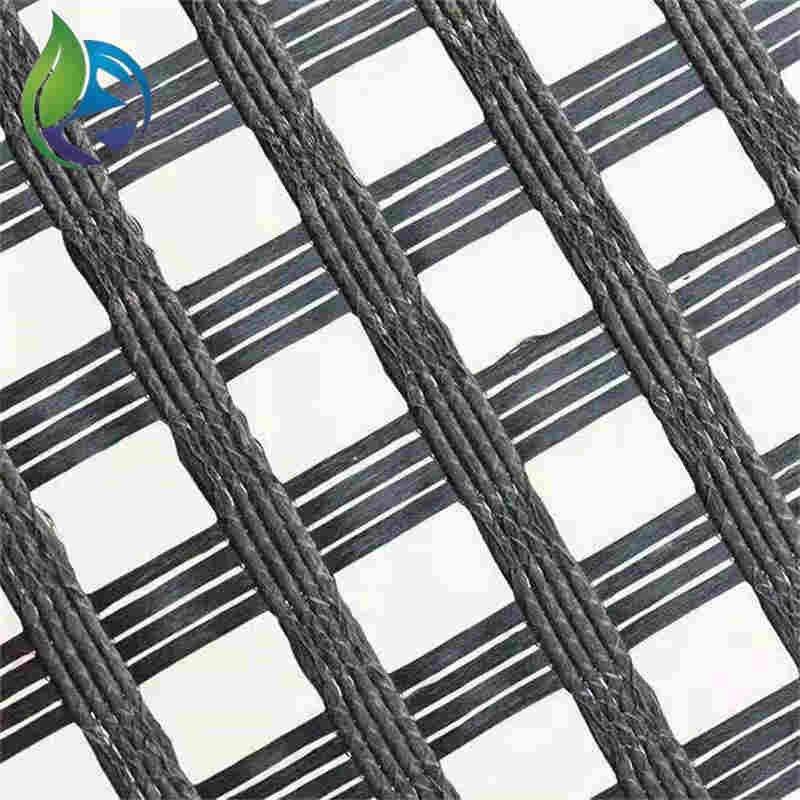

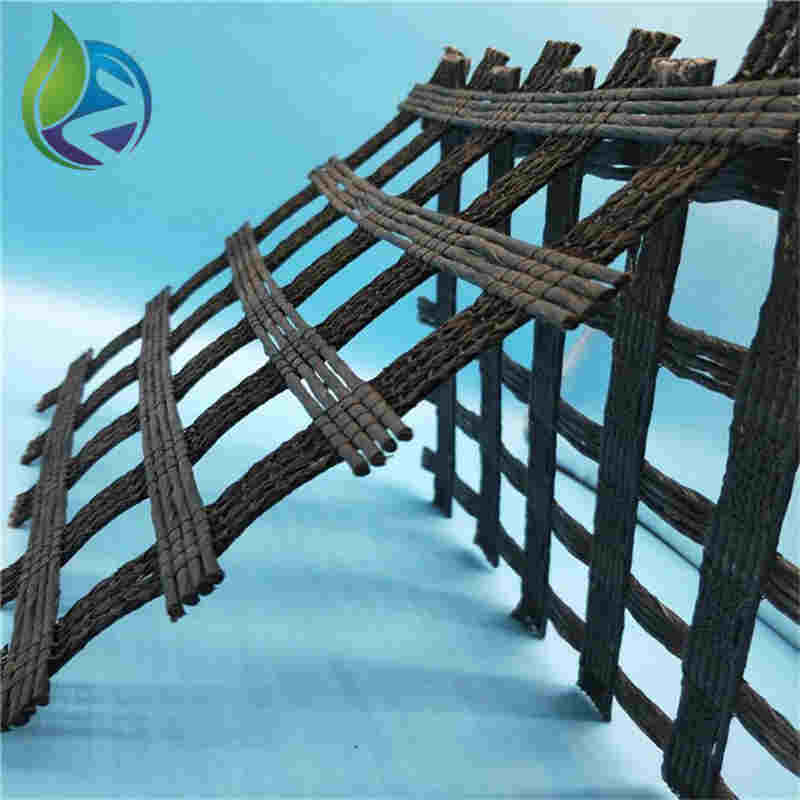

Warp knitting polyester geogrid for road & highway construction is a grid-like material made from high-tenacity polyester yarns woven in a warp-knitted pattern and coated with PVC or other polymers. The warp knitting technique allows for precise alignment and strong interlocking between soil particles and aggregate layers, significantly improving structural stability.

Key Features:

High tensile strength in both longitudinal and transverse directions

Excellent chemical and UV resistance

Superior dimensional stability

Minimal elongation under load

Lightweight and easy to install

These properties make warp knitting polyester geogrid for road & highway construction ideal for heavy-duty traffic zones and long-term infrastructure resilience.

Benefits of Warp Knitting Polyester Geogrid for Road & Highway Construction

Enhanced Load Distribution

Using warp knitting polyester geogrid for road & highway construction distributes vehicular loads evenly, preventing rutting and surface cracking while prolonging the service life of pavements.Subgrade Stabilization

Poor soil conditions are common challenges in construction. Warp knitting polyester geogrid for road & highway construction strengthens the subgrade, reducing differential settlement and increasing overall ground stability.Cost Efficiency

By minimizing the need for thick gravel layers and reducing future maintenance, warp knitting polyester geogrid for road & highway construction offers long-term cost savings for infrastructure projects.Easy Handling and Installation

The lightweight nature of warp knitting polyester geogrid for road & highway construction simplifies transport and deployment, accelerating construction timelines.Environmental Sustainability

Less excavation and reduced material use means that warp knitting polyester geogrid for road & highway construction supports green building practices and helps minimize the project’s environmental impact.

Applications of Warp Knitting Polyester Geogrid for Road & Highway Construction

Warp knitting polyester geogrid for road & highway construction is extensively used in:

Highways and expressways

Rural and urban roads

Airport runways

Railroad embankments

Parking lots and logistics centers

Bridge approach embankments

In every case, warp knitting polyester geogrid for road & highway construction enhances durability and safety under constant dynamic loads.

How to Install Warp Knitting Polyester Geogrid

Installing warp knitting polyester geogrid for road & highway construction involves a straightforward process:

Prepare the subgrade by leveling and compacting the soil.

Lay the geogrid flat, ensuring there are no wrinkles or overlaps.

Secure the edges and overlaps using pins or staples if necessary.

Place the base material (gravel or aggregate) over the geogrid.

Compact and level the base to integrate the geogrid fully.

This seamless process helps optimize performance and ensures the long-term integrity of road and highway structures.

Choosing the Right Warp Knitting Polyester Geogrid

When selecting warp knitting polyester geogrid for road & highway construction, consider the following:

Tensile strength (e.g., 50–400 kN/m)

Mesh size for proper aggregate interlock

Coating type for durability in harsh environments

Project-specific soil and load conditions

Working with a qualified supplier ensures you get the best warp knitting polyester geogrid for road & highway construction to meet your exact engineering requirements.

Conclusion

Warp knitting polyester geogrid for road & highway construction is a reliable, cost-effective, and environmentally responsible solution for improving road foundation strength and longevity. Its superior performance under heavy loads, resistance to harsh conditions, and ease of use make it indispensable in modern infrastructure projects.