Filament Geotextile for Sale

Filament geotextile is an essential material in railway construction, providing crucial separation and reinforcement functions. Its exceptional strength and durability allow it to effectively isolate different soil layers and materials, preventing their mixing and enhancing the structural stability of the railway. As a reinforcement agent, filament geotextile significantly improves the load-bearing capacity of the soil, reducing the risk of settlement or deformation. Moreover, its anti-aging properties ensure reliable performance even in harsh environments, making it a trusted choice for railway separation and reinforcement applications.

Filament Geotextile Separation and Reinforcement for Railway

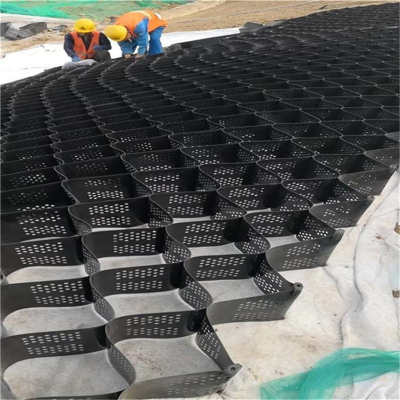

Filament geotextile separation and reinforcement for railway systems plays a crucial role in enhancing the performance, longevity, and safety of modern rail infrastructure. This engineered solution provides an effective barrier between different soil layers while simultaneously offering structural support. In railway construction, where ground stability and drainage are vital, filament geotextile separation and reinforcement for railway is increasingly becoming the material of choice.

Key Functions in Railway Applications

1. Separation

The primary use of filament geotextile separation and reinforcement for railway is to prevent the mixing of subgrade soil and aggregate materials. Without a separation layer, fine particles can migrate upward into the ballast, leading to reduced drainage capacity and faster degradation of the track bed. The geotextile maintains the structural integrity of each layer, ensuring consistent performance over time.

2. Reinforcement

By distributing applied loads over a wider area, filament geotextile separation and reinforcement for railway enhances the overall strength of the railway foundation. It improves the bearing capacity of weak soils and minimizes settlement. The reinforcement effect is critical in areas with soft or variable ground conditions, where traditional construction methods may not provide sufficient support.

3. Filtration and Drainage

An important feature of filament geotextile separation and reinforcement for railway is its ability to allow water to pass through while retaining soil particles. This filtration function prevents clogging and maintains proper drainage, which is essential for the long-term stability of railway embankments and subgrades.

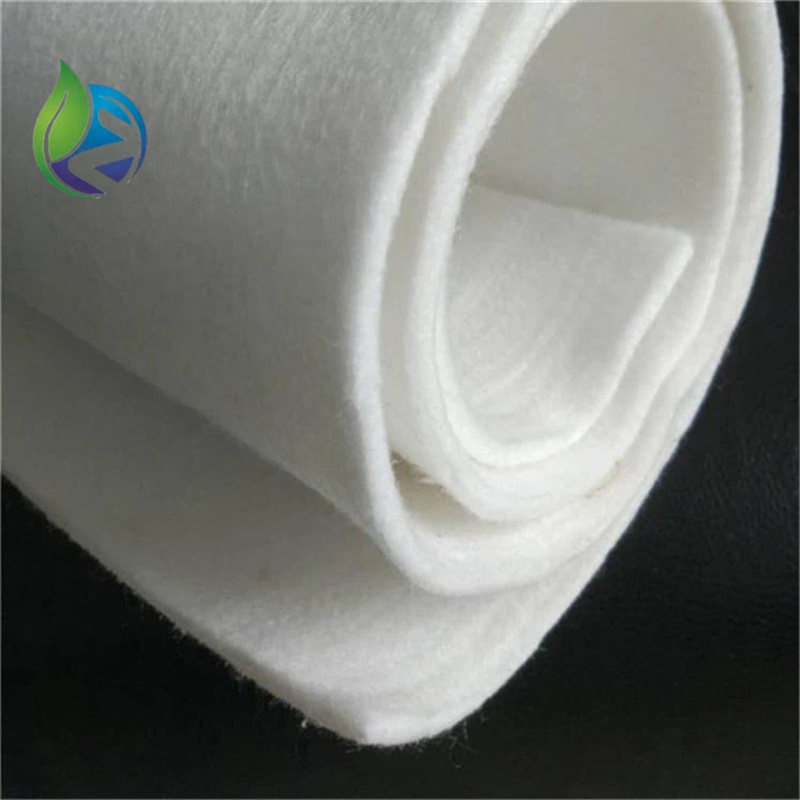

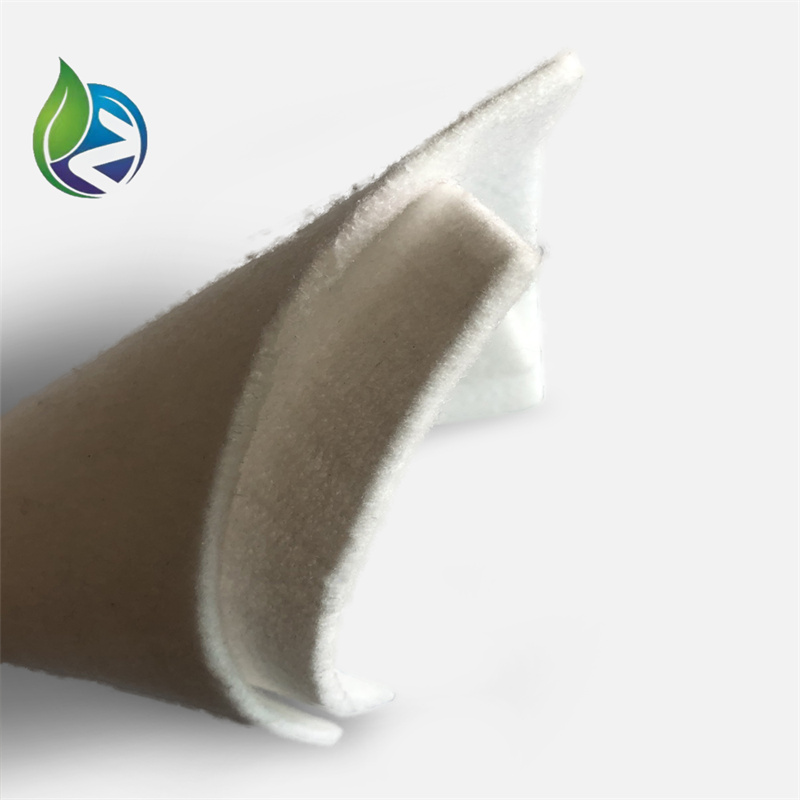

What is Filament Geotextile?

Filament geotextile is a synthetic fabric made from continuous polyester or polypropylene filaments that are thermally bonded. This durable, nonwoven textile exhibits high tensile strength and excellent filtration capabilities. The primary functions of filament geotextile separation and reinforcement for railway include preventing the intermixing of subgrade and ballast, distributing loads evenly, and improving soil strength under repeated train loads.

Benefits of Using Filament Geotextile in Railway Engineering

Improved Track Stability

The consistent separation and reinforcement provided by filament geotextile separation and reinforcement for railway ensure that the track remains level and well-supported, reducing maintenance needs.Enhanced Load Distribution

Train loads, especially from heavy freight or high-speed systems, are better managed with filament geotextile, minimizing deformation of the subgrade.Reduced Maintenance Costs

By preventing contamination of the ballast layer and improving drainage, filament geotextile separation and reinforcement for railway helps prolong the lifespan of the track system and reduces the frequency of repairs.Environmental Resistance

Filament geotextiles are resistant to biological and chemical degradation, ensuring long-term performance even in harsh environmental conditions.

Installation in Railway Construction

Installing filament geotextile separation and reinforcement for railway involves placing the fabric directly over the prepared subgrade before adding the ballast layer. Proper overlap and anchoring are essential to ensure continuous coverage and performance. The geotextile must be selected based on project-specific load requirements, soil conditions, and anticipated environmental exposure.

Applications Beyond Railways

Although optimized for railway projects, filament geotextile separation and reinforcement for railway is also widely used in:

Highway embankments

Airport runways

Retaining walls

Coastal erosion control

Landfill caps and liners

This versatility demonstrates the material’s wide-reaching benefits in both infrastructure and environmental engineering.

Why Choose Filament Geotextile for Rail Projects?

Long-Term Performance: High durability and chemical resistance.

Cost-Effective Solution: Reduces ballast contamination and track failures.

Engineered Reliability: Withstands dynamic and static train loads.

Eco-Friendly Option: Minimizes resource consumption through extended track life.

When engineers prioritize reliability and sustainability, filament geotextile separation and reinforcement for railway stands out as the optimal solution.

Filament geotextile separation and reinforcement for railway is a proven, high-performance solution that addresses the structural challenges of modern rail systems. By combining the key functions of separation, reinforcement, and filtration, this geotextile ensures safe, durable, and low-maintenance railway infrastructure. Its adaptability and strength make it an indispensable material for both new railways and rehabilitation projects.