Composite Net for Drainage

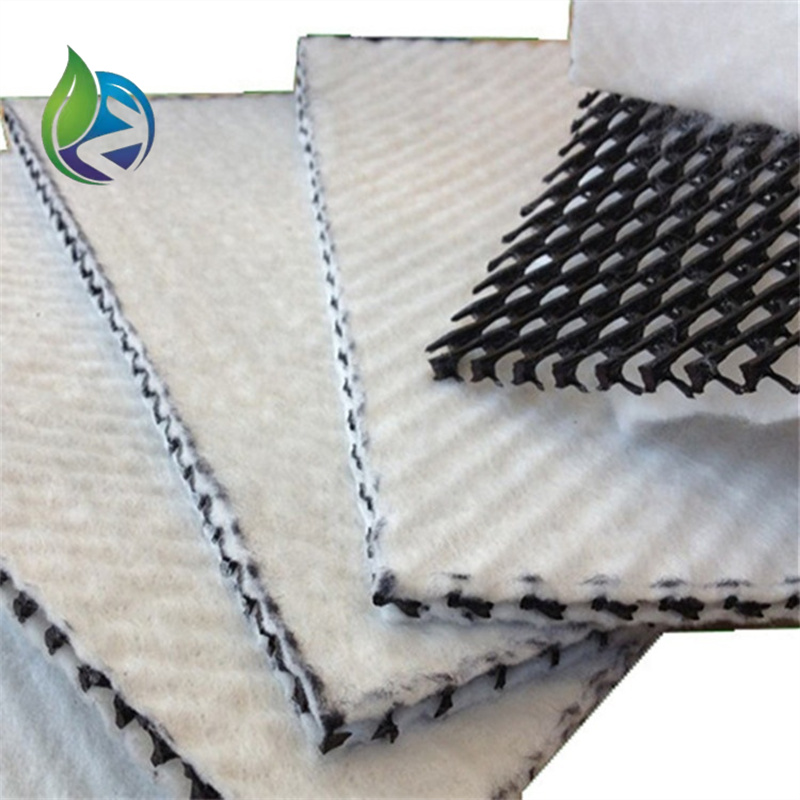

The three-dimensional composite drainage geonet is an innovative geosynthetic material composed of a high-density polyethylene (HDPE) plastic mesh as its core, with one side bonded to a filter geotextile and the other side to an impermeable geomembrane. This material is uniquely designed with a pore maintenance system that can block capillary water under high loads and serves as an isolation and foundation reinforcement. It is primarily used for drainage in landfill sites, roadbeds, and tunnel walls, effectively replacing traditional layers of sand and gravel. When laid between the foundation and subbase, it can rapidly drain water, block capillary water, and effectively integrate into the edge drainage system, shortening the drainage path and time. Additionally, it prevents fine materials from the subbase from entering the foundation, serving as an isolation layer. In transportation infrastructure projects, the three-dimensional composite drainage network plays a crucial role in the drainage system, impacting the safety and service life of the project.

HDPE Geotextile Geonet Composite for Drainage: Reliable Solution for Subsurface Water Management

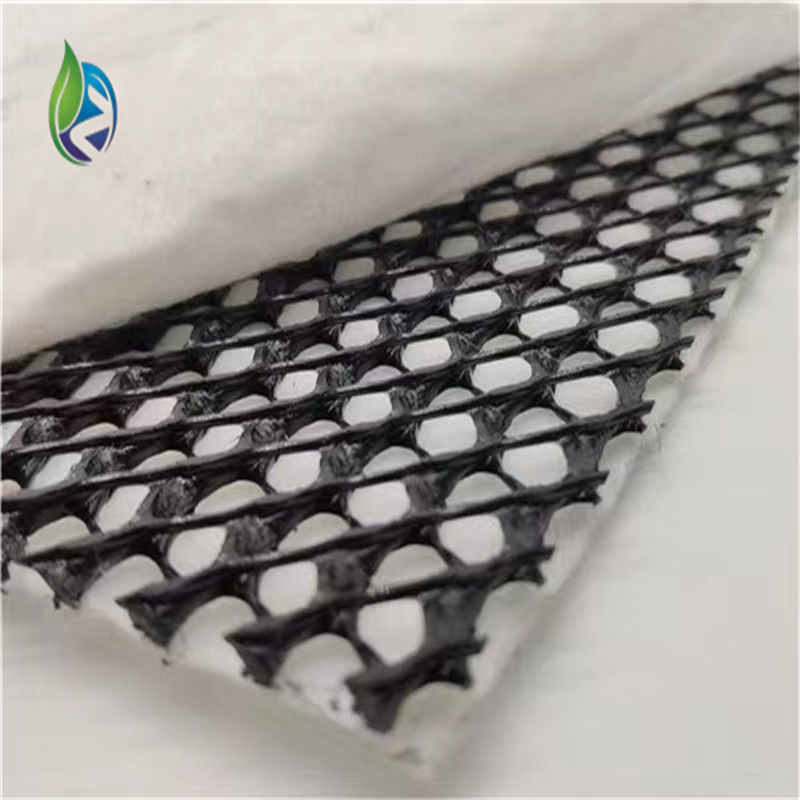

HDPE geotextile geonet composite for drainage is a high-performance geosynthetic material engineered for efficient fluid transmission and filtration in civil, environmental, and geotechnical engineering projects. Designed by bonding a high-density polyethylene (HDPE) geonet core with one or two layers of nonwoven geotextile, the HDPE geotextile geonet composite for drainage provides both separation and drainage in one integrated system.

What Is HDPE Geotextile Geonet Composite for Drainage?

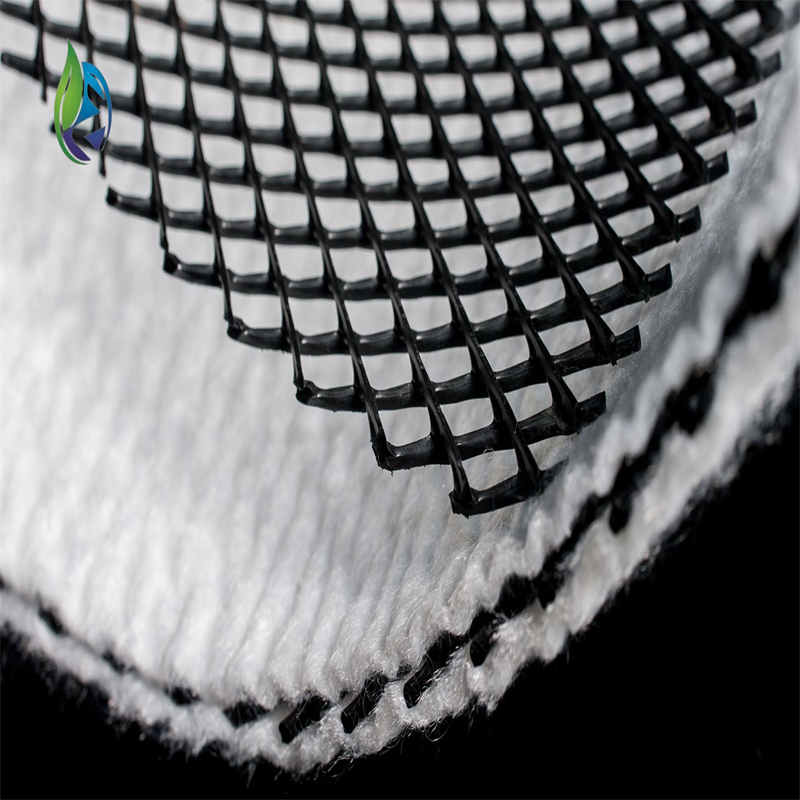

The HDPE geotextile geonet composite for drainage consists of a three-dimensional HDPE geonet core laminated with geotextiles on one or both sides. The geonet functions as the drainage medium, while the geotextile layers filter soil particles and protect the core from clogging. This structure is ideal for rapid drainage, long-term performance, and easy installation in a variety of drainage systems.

The HDPE geotextile geonet composite for drainage is especially suitable for use under landfill caps, road embankments, retaining walls, tunnel linings, and green roofs where both water transmission and soil separation are required.

Key Features of HDPE Geotextile Geonet Composite for Drainage

Excellent Drainage Capacity

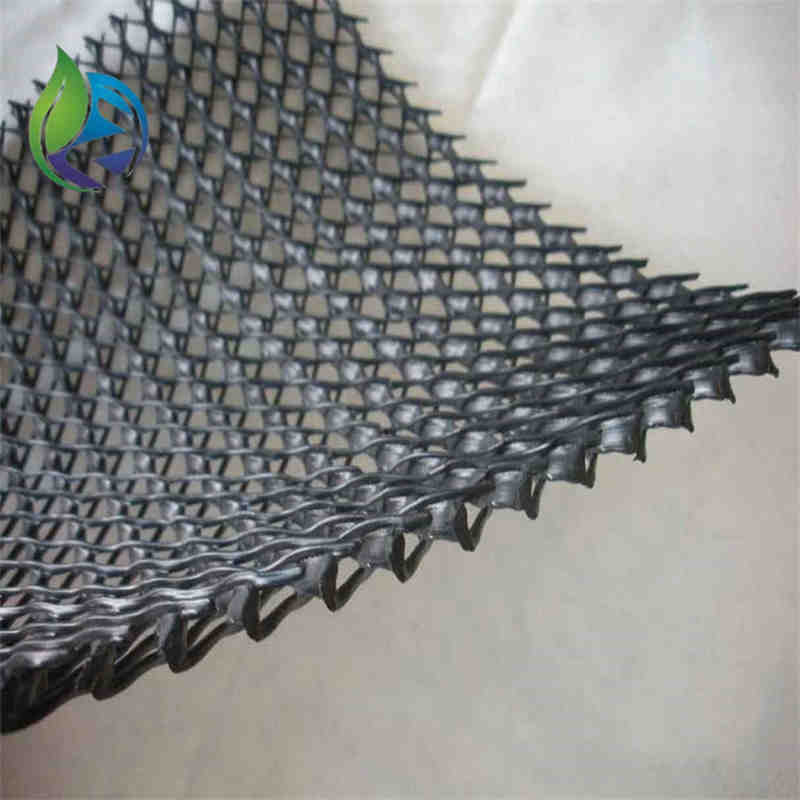

The three-dimensional core of the HDPE geotextile geonet composite for drainage ensures high flow rates under load, enabling rapid water discharge and pressure relief.Superior Filtration and Protection

The bonded nonwoven geotextile layers in the HDPE geotextile geonet composite for drainage prevent soil intrusion while maintaining water permeability.High Tensile and Compression Strength

Engineered from virgin HDPE, the HDPE geotextile geonet composite for drainage resists deformation under heavy loads and long-term stress.Chemical and UV Resistance

The HDPE geotextile geonet composite for drainage is stable against acids, alkalis, and exposure to UV rays, making it ideal for exposed or buried applications.Lightweight and Easy to Install

The composite material is easy to cut, transport, and install, reducing labor and equipment costs.

Applications of HDPE Geotextile Geonet Composite for Drainage

The HDPE geotextile geonet composite for drainage is widely used in:

Landfill Drainage Systems

Placed beneath landfill liners or caps to quickly remove leachate and reduce hydrostatic pressure.Retaining Wall Backfill Drainage

Prevents water buildup behind retaining structures and ensures soil stability.Road and Highway Subgrade Drainage

Enhances pavement life by efficiently draining subsurface water.Tunnel and Subway Waterproofing

Channels water away from structures to avoid seepage and structural damage.Roof Gardens and Green Roofs

Facilitates excess water removal while allowing root penetration and aeration.

Each of these applications benefits from the high efficiency of HDPE geotextile geonet composite for drainage in managing water flow and maintaining structural integrity.

Installation Tips for HDPE Geotextile Geonet Composite for Drainage

To ensure the best performance of HDPE geotextile geonet composite for drainage, follow these best practices:

Surface Preparation

Clean and level the subgrade before placing the composite to avoid puncture and voids.Proper Alignment

Roll out the HDPE geotextile geonet composite for drainage in the direction of water flow for optimal drainage efficiency.Overlap and Seam Joining

Maintain adequate overlap (usually 10–20 cm) between adjacent rolls and use heat welding or sealing tape where necessary.Backfill Carefully

Place protective layers gently over the composite to avoid compression or movement during backfilling.

Why Choose HDPE Geotextile Geonet Composite for Drainage?

Combines filtration, separation, and drainage in one product

High flow capacity under high loads

Long service life in buried or exposed conditions

Compatible with most geomembranes and waterproofing layers

Cost-effective solution for complex drainage designs

Conclusion

Efficient water management is critical in modern infrastructure. HDPE geotextile geonet composite for drainage provides a durable, efficient, and easy-to-install solution for subsurface drainage across a range of civil and environmental engineering applications. Its multi-functional design minimizes material usage and simplifies installation, delivering superior performance in both vertical and horizontal drainage systems.