Geomembrane with high tensile strength

Manufacturing Process

Industrial manufacturing of geomembrane with high tensile strength follows controlled engineering steps:

Resin drying and gravimetric dosing of polymer and additives

Twin-screw extrusion compounding

Flat die or blown film extrusion forming

Online thickness monitoring by laser gauge systems

Surface texturing via embossed roller systems

Cooling by water bath or air ring systems

Automatic edge trimming and winding

Roll inspection and mechanical property testing

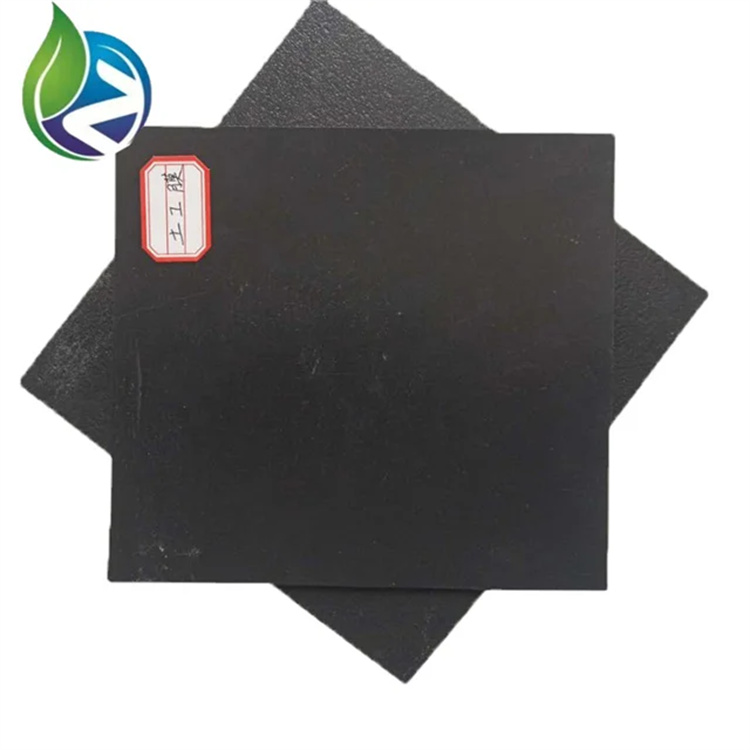

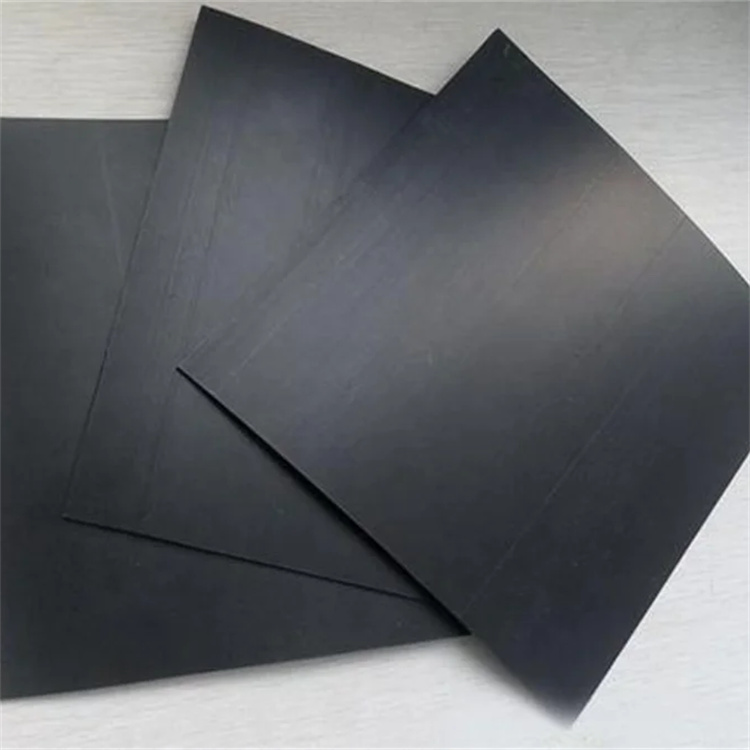

Product Definition

Geomembrane with high tensile strength is a polymer-based impermeable liner engineered to withstand high mechanical stress while providing long-term hydraulic containment, used in geotechnical and environmental engineering projects requiring superior load resistance, puncture resistance, and deformation control under complex field conditions.

Technical Parameters and Specifications

Typical technical parameters for geomembrane with high tensile strength used in industrial and civil projects are as follows:

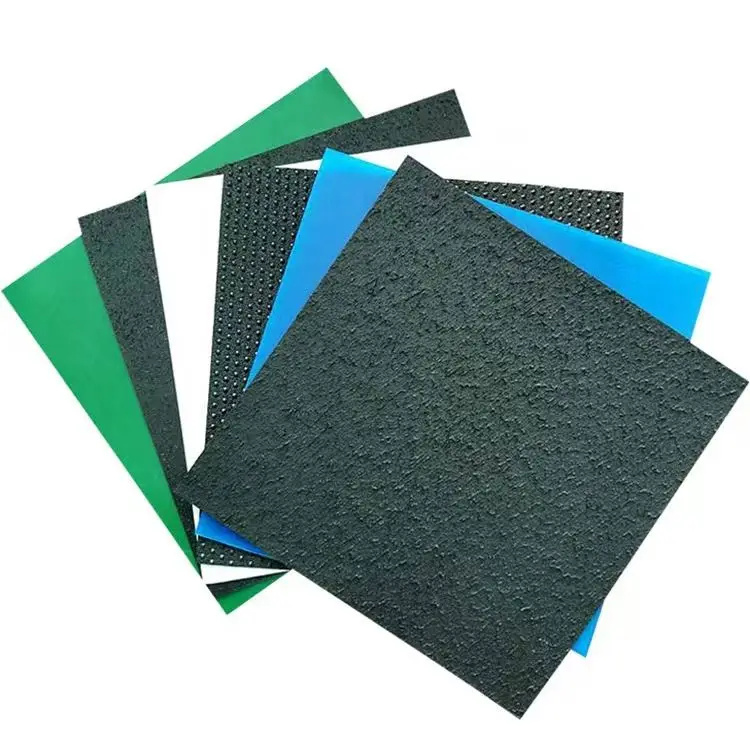

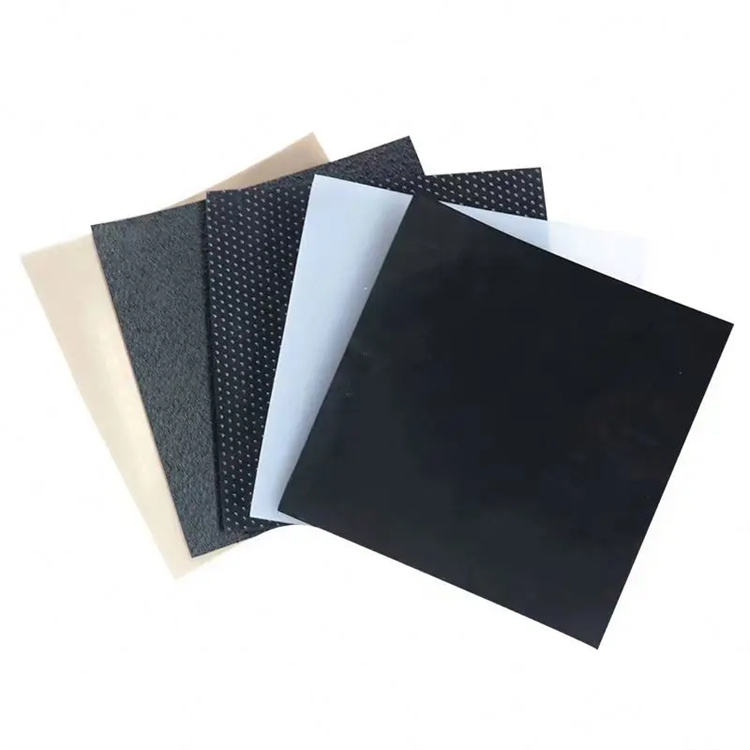

Base polymer: HDPE, LLDPE, or reinforced PVC

Standard thickness range: 0.5 mm – 3.0 mm

Density (HDPE type): 0.94 g/cm³ – 0.96 g/cm³

Tensile strength at yield: 16–28 MPa

Tensile strength at break: 22–35 MPa

Elongation at break: 600% – 800

Puncture resistance: 600 – 1200 N

Tear resistance: 200 – 400 N

Carbon black content: 2.0% – 3.0%

Service temperature range: -40°C to +60°C

Design service life: 20 – 30 years in buried applications

Structure and Material Composition

The geomembrane with high tensile strength adopts a multilayer structural design:

Top surface layer: UV-stabilized polymer skin

Core layer: High-density polyethylene or reinforced composite core

Reinforcement layer (optional): Polyester or glass fiber grid

Bottom layer: Anti-slip or textured functional layer

Additives: Carbon black, antioxidants, and thermal stabilizers

Manufacturing Process

Industrial manufacturing of geomembrane with high tensile strength follows controlled engineering steps:

Resin drying and gravimetric dosing of polymer and additives

Twin-screw extrusion compounding

Flat die or blown film extrusion forming

Online thickness monitoring by laser gauge systems

Surface texturing via embossed roller systems

Cooling by water bath or air ring systems

Automatic edge trimming and winding

Roll inspection and mechanical property testing

Industry Comparison

| Material Type | Tensile Strength | Puncture Resistance | Service Life | Typical Cost Level |

|---|---|---|---|---|

| Geomembrane with High Tensile Strength | High | High | 20–30 Years | Medium |

| Standard HDPE Geomembrane | Medium | Medium | 15–20 Years | Low |

| PVC Geomembrane | Low–Medium | Low | 10–15 Years | Low |

| Bituminous Liners | Low | Low | 8–12 Years | Low |

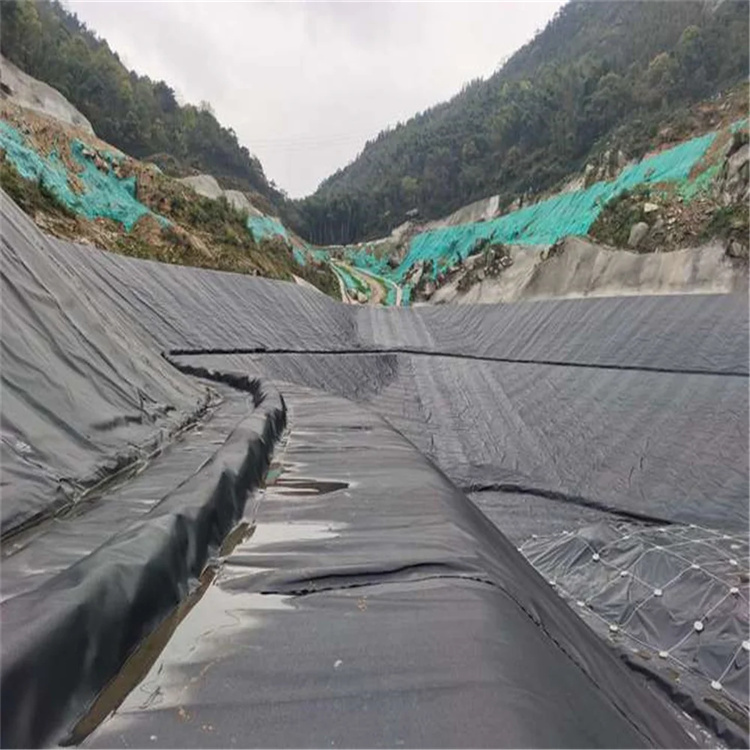

Application Scenarios

The geomembrane with high tensile strength is widely adopted by:

Distributors of geosynthetic construction materials

EPC contractors for environmental and hydraulic projects

Civil engineering contractors managing landfill and tailings projects

Infrastructure developers for water containment systems

Typical engineering uses include landfill liners, mining tailings ponds, water reservoirs, canal lining, biogas digesters, and industrial wastewater treatment ponds.

Core Pain Points and Solutions

Risk of tearing under heavy soil load — solved by using high tensile core formulations

Puncture damage from sharp aggregates — mitigated by increased thickness and protective geotextile layers

Long-term UV degradation — reduced by carbon black and UV-stabilized resin systems

Seam failure risk — addressed by automated hot wedge and extrusion welding methods

Risk Warnings and Mitigation Recommendations

Incorrect subgrade preparation may cause local stress concentration — perform ground leveling and remove sharp debris

Improper welding parameters can weaken seams — use calibrated welding equipment and real-time seam testing

Thermal expansion may generate wrinkling — install during controlled temperature windows

Incompatible chemical exposure may degrade polymer — verify chemical resistance charts before material selection

Procurement and Selection Guide

Define project hydraulic and mechanical loading requirements

Select polymer type based on chemical and temperature exposure

Determine minimum thickness according to design codes

Verify tensile and puncture test reports from accredited laboratories

Request factory quality control and traceability documentation

Confirm compatibility with available welding equipment on site

Evaluate long-term maintenance and inspection plans

Engineering Case Example

In a mining tailings storage facility project, a geomembrane with high tensile strength with 2.0 mm thickness was installed over a compacted clay liner and nonwoven geotextile. The system covered approximately 45,000 m² and was hot wedge welded with dual-track seams. Post-installation testing showed stable tensile performance under long-term static load and improved resistance to deformation from tailings settlement.

FAQ

Q1: What tensile strength is considered high for geomembranes?

A: Typically above 20 MPa.Q2: Can the geomembrane be used in chemical ponds?

A: Yes, if chemically compatible with the fluid.Q3: What thickness is recommended for landfills?

A: Commonly 1.5–2.0 mm.Q4: How are seams tested?

A: By air pressure or vacuum box testing.Q5: Is UV resistance mandatory for buried installations?

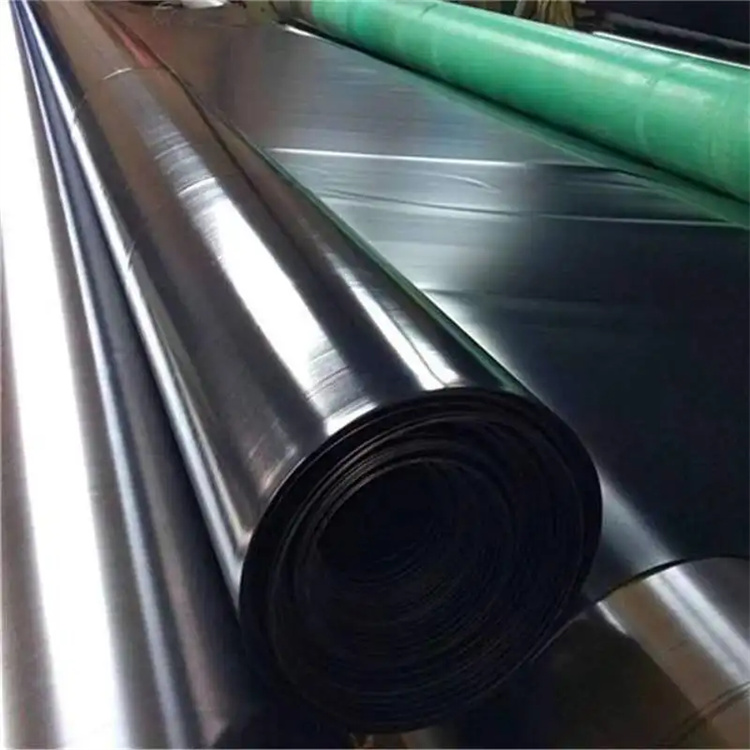

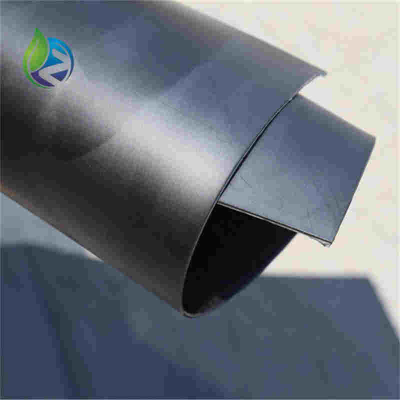

A: Beneficial during construction and exposed phases.Q6: What is the typical roll width?

A: 5–8 meters.Q7: Can it handle differential settlement?

A: Yes, within design elongation limits.Q8: How long can it be exposed before covering?

A: Typically 2–4 weeks, depending on climate.Q9: Does it require special storage conditions?

A: Store away from direct UV and standing water.Q10: What standards govern testing?

A: ASTM and ISO geosynthetics standards.

CTA – Commercial Technical Request

For formal project procurement, request commercial quotation, detailed technical datasheets, and engineering samples of geomembrane with high tensile strength through official technical sales channels.

E-E-A-T Author Credentials

This document is prepared by geotechnical engineers and materials specialists with more than 15 years of experience in geosynthetics design, large-scale containment engineering, and international EPC project consulting, ensuring reliable technical guidance for professional B2B decision makers.

Geomembrane construction precautions:

Construction preparation: Before construction, the base surface should be levelled to ensure that no sharp objects protruded, so as not to puncture the soil diaphragm.

At the same time, the required leveling materials such as sand or clay, as well as welding equipment, should be prepared.

Laying and welding: When laying HDPE geomemofilm, it should be naturally developed to avoid excessive stretching or discounting. The two adjacent geomembranes

should be connected by thermal welding or special tape to ensure the sealing of the joints. When welding, the temperature and time should be controlled to avoid

overheating or undercooling leading to poor welding quality.

Inspection and acceptance: After the completion of construction, the HDPE geomembrane should be comprehensively inspected to ensure that it has no defects

such as damage, no bubbles, and no wrinkles. At the same time, acceptance tests, such as leakage tests, should also be carried out to ensure that its anti-seepage

performance meets the requirements.