Practical Ways to Extend the Lifespan of HDPE Geomembrane

Practical Ways to Extend the Lifespan of HDPE Geomembrane

Introduction

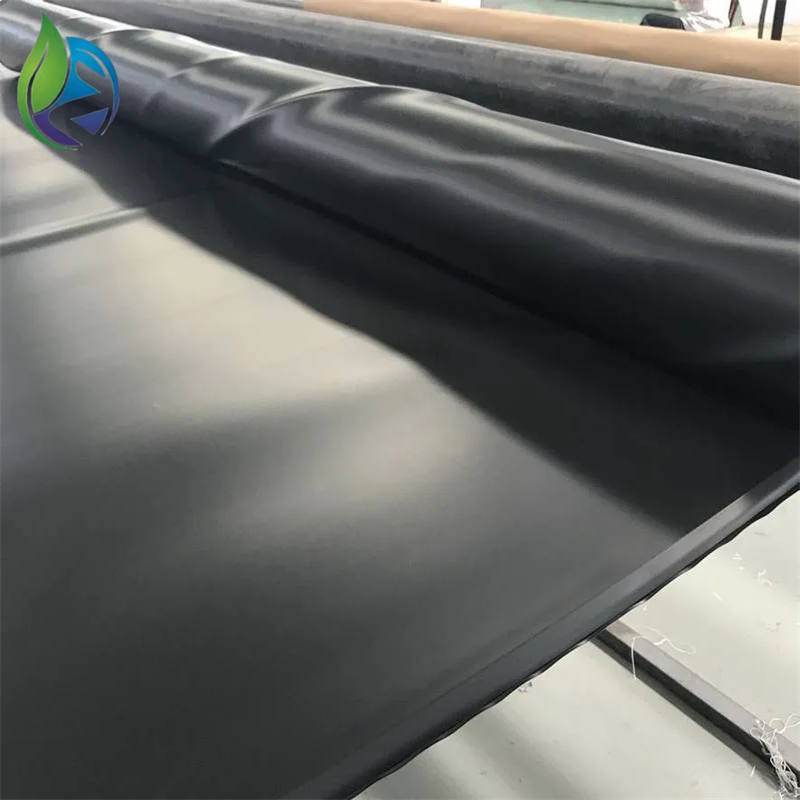

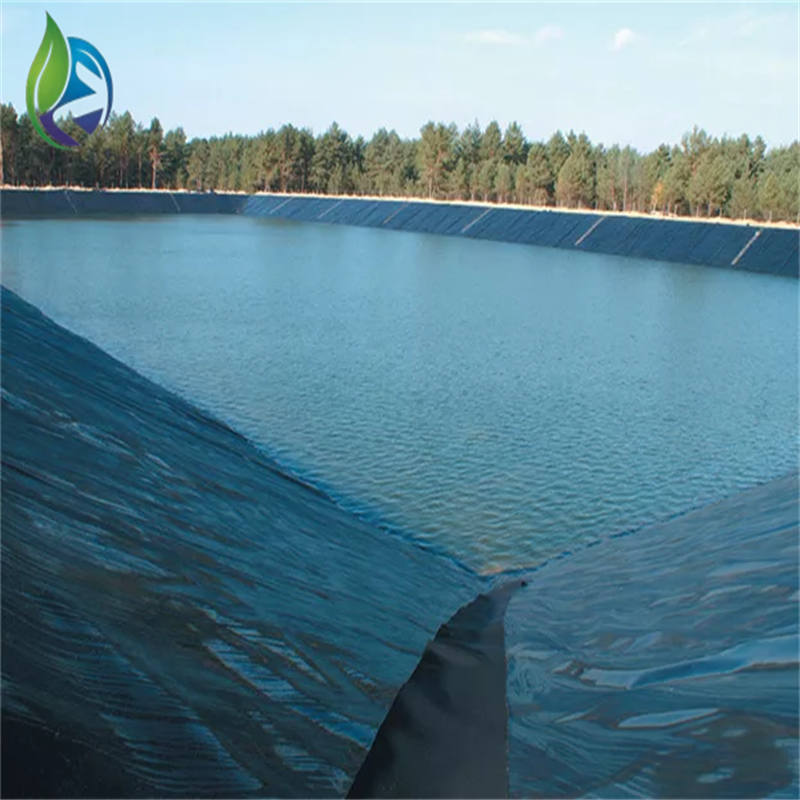

HDPE geomembrane is one of the most commonly used materials in environmental protection projects, including landfills, pond liners, and stormwater management systems. Known for its excellent chemical resistance, durability, and low permeability, HDPE (High-Density Polyethylene) geomembrane has become a staple in various industries. However, like any construction material, the longevity of HDPE geomembrane depends on several factors, including proper installation, maintenance, and environmental conditions.

In this article, we will explore practical ways to extend the lifespan of HDPE geomembrane, ensuring that it remains effective in protecting the environment and underlying structures. Whether you are involved in landfill management, waterproofing, or any other project requiring geomembranes, these strategies will help maximize the performance and durability of your HDPE liners.

The Importance of HDPE Geomembrane Longevity

Before delving into specific strategies, it's essential to understand why extending the lifespan of HDPE geomembranes is critical. Geomembranes serve as barriers to prevent contaminants from leaching into the surrounding environment. In landfill operations, for example, they act as liners that protect the soil and groundwater from hazardous waste. In water applications, geomembranes serve as effective waterproofing solutions.

The cost of replacing damaged geomembranes or addressing environmental consequences from failed liners can be significant. By taking steps to extend the life of HDPE geomembranes, you can save on operational costs and reduce environmental risks.

Key Factors Affecting the Lifespan of HDPE Geomembrane

Several elements can affect the longevity of HDPE geomembranes, including:

1. UV Exposure

HDPE geomembranes are susceptible to degradation from prolonged exposure to ultraviolet (UV) radiation from the sun. Over time, UV rays can break down the polymer chains in HDPE, leading to brittleness and cracking. This is particularly important in outdoor applications like landfills and ponds, where geomembranes are exposed to direct sunlight for extended periods.

2. Chemical Exposure

HDPE geomembranes are known for their excellent chemical resistance, but extreme exposure to certain chemicals, such as aggressive acids or alkalis, can cause degradation. Industries using geomembranes in wastewater treatment or chemical containment need to monitor and assess chemical exposure levels carefully.

3. Mechanical Stress

Physical damage is another significant factor that can reduce the lifespan of HDPE geomembranes. This can result from mechanical stress during installation, sharp objects in the surrounding environment, or pressure from external loads. Careful handling and installation are crucial to minimizing physical damage.

4. Temperature Fluctuations

Temperature extremes—especially rapid fluctuations—can lead to expansion and contraction of the HDPE geomembrane, increasing the risk of cracking. High temperatures, particularly in regions with hot summers and cold winters, can also reduce the material's flexibility, making it more prone to failure.

Practical Ways to Extend the Lifespan of HDPE Geomembrane

Now that we understand the factors affecting the lifespan of HDPE geomembranes, let's explore some practical strategies that can help extend their effectiveness and longevity.

1. Proper Installation Techniques

The foundation of a long-lasting HDPE geomembrane begins with proper installation. Ensuring that the geomembrane is laid correctly can prevent numerous issues down the line.

Seam Welding: High-quality seam welding is crucial to ensuring the integrity of the geomembrane. Overlap welding or extrusion welding should be done with precision to create seamless joints that prevent leaks and seepage.

Careful Handling: During installation, the geomembrane must be handled with care to avoid punctures and tears. It’s essential to protect the material from sharp objects and other damage during transportation and placement.

Thickness Selection: Choosing the appropriate thickness for the geomembrane is another essential factor. Thicker materials tend to be more resistant to mechanical stress and punctures, thus providing better long-term protection.

2. Use UV Protection Additives

In applications where HDPE geomembranes are exposed to significant sunlight, incorporating UV stabilizers or additives can greatly extend the material’s lifespan. These stabilizers work by slowing down the breakdown of polymer chains caused by UV rays, ensuring that the geomembrane remains flexible and resistant to cracking.

For projects with high UV exposure, it’s recommended to use HDPE geomembranes with built-in UV protection or add a protective UV coating during installation.

3. Periodic Inspections and Maintenance

Regular inspections are crucial to identifying potential issues early and extending the lifespan of HDPE geomembranes. Routine checks can help identify signs of wear and tear, punctures, or chemical damage that may compromise the system's effectiveness.

Visual Inspections: Inspect the geomembrane for any visible signs of physical damage, such as cracks or holes. Pay special attention to seams and joints, as these are common failure points.

Cleaning: Keeping the geomembrane clean from debris, soil, and vegetation can reduce the risk of mechanical damage and ensure proper water drainage.

Repairs: Any damage found during inspections should be repaired promptly using appropriate materials. For small holes or tears, a specialized geomembrane patch or welding system can be used for effective repairs.

4. Reduce Mechanical Stress

Minimizing external mechanical stress can help protect the HDPE geomembrane from unnecessary wear. This includes:

Avoiding heavy equipment or vehicles driving over the geomembrane.

Ensuring that the surrounding landscape and soil do not exert excessive pressure on the geomembrane.

Using a protective layer, such as a geotextile fabric, to shield the geomembrane from punctures caused by sharp objects in the soil.

5. Temperature Management

While HDPE geomembranes are designed to withstand a range of temperatures, extreme temperature fluctuations can still cause damage. Where possible, temperature management should be part of the design. In colder climates, insulating layers or temperature-controlled environments may be used to minimize the thermal expansion and contraction of the geomembrane.

Frequently Asked Questions (FAQ)

1. How long does an HDPE geomembrane typically last?

With proper installation and regular maintenance, an HDPE geomembrane can last between 20 to 30 years. Some applications, like landfill liners, can even extend the lifespan with ongoing care and UV protection.

2. Can HDPE geomembranes be repaired if damaged?

Yes, HDPE geomembranes can be repaired using specialized welding or patching techniques. Small tears can be fixed with geomembrane patches, while larger damages may require welding for a seamless fix.

3. What is the best way to protect HDPE geomembrane from UV damage?

Adding UV stabilizers to the geomembrane during installation or using geomembranes specifically designed for high UV exposure can effectively extend their lifespan. Protective coatings are also available for extra protection.

4. Can HDPE geomembranes be used in all climates?

HDPE geomembranes can be used in most climates, but extreme temperature fluctuations or excessive UV exposure can shorten their lifespan. Protective layers, UV additives, and regular maintenance can help mitigate these risks.

Conclusion

Extending the lifespan of HDPE geomembranes is not only cost-effective but also essential for protecting your investment in infrastructure and environmental projects. By following proper installation procedures, using UV stabilizers, performing regular maintenance, and reducing mechanical stress, you can significantly increase the durability and effectiveness of your geomembrane liner.

Whether you're working on a landfill, a pond liner, or any other waterproofing project, implementing these strategies will ensure the longevity of your geomembrane. Contact us today to learn more about how you can protect your investment and extend the life of your HDPE geomembrane.