The 'Anti-Settling' Logic of Geogrids in Road Engineering

In street engineering, contract is a continual and tough issue. It now not solely shortens the carrier existence of roads however additionally will increase renovation costs, and in extreme cases, even endangers site visitors safety. To tackle this problem, more than a few engineering substances and applied sciences have been developed and applied, amongst which geogrid material has progressively end up a key pressure in resisting contract due to its special overall performance advantages. This article will delve into the "anti-settling" good judgment of geogrid material in street engineering, exploring how it performs its position from more than one perspectives.

The Structural Characteristics of Geogrid Material: The Foundation of Anti-Settling

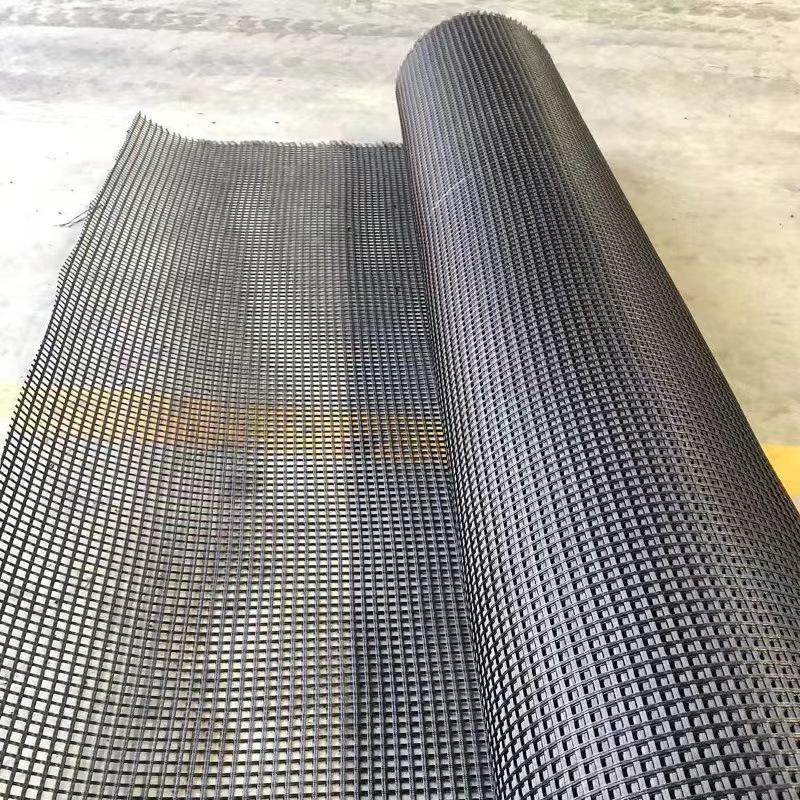

Geogrid material is a form of polymer artificial fabric with a grid-like structure, which is normally made of polypropylene, polyethylene, or polyester via procedures such as stretching. Its structural traits lay a stable basis for its anti-settling characteristic in street engineering.

The grid shape of geogrid material is its most exclusive feature. The dimension and structure of the grid are designed in accordance to unique engineering needs. Generally, the grid aperture levels from a few millimeters to quite a few centimeters. This shape approves soil particles to penetrate into the grid, forming a shut aggregate between the geogrid and the soil. When the street is subjected to exterior loads, the grid can disperse the stress to a large range, decreasing the stress awareness on the neighborhood soil and as a consequence inhibiting the incidence of settlement.

In addition, geogrid material has excessive tensile power and modulus of elasticity. Under the motion of exterior forces, it is now not handy to deform, which can efficaciously avert the lateral displacement of the soil. In avenue engineering, when the soil is beneath pressure, it tends to enlarge laterally. The existence of geogrid material can restriction this lateral expansion, making the soil greater compact and enhancing the ordinary balance of the roadbed, thereby decreasing the opportunity of settlement.

The Interaction Mechanism Between Geogrid Material and Soil: The Core of Anti-Settling

The anti-settling impact of geogrid material in street engineering is now not carried out with the aid of itself alone, however thru its shut interplay with the soil. This interplay mechanism is the core of its anti-settling logic.

On one hand, there is a frictional pressure between geogrid material and the soil. The floor of the geogrid is typically designed with positive roughness, which will increase the friction coefficient between it and the soil. When the soil is about to slide or deform, this frictional pressure can stop the relative motion between the soil and the geogrid, making the two structure a unified stress system. This unified device can higher stand up to exterior masses and minimize the contract prompted via soil displacement.

On the different hand, geogrid material can play a function in reinforcing the soil. When the geogrid is embedded in the soil, it can enhance the shear electricity of the soil. The shear power of the soil is an vital indicator to measure its capability to withstand deformation. By growing the shear strength, the soil is no longer convenient to shear and fail beneath the motion of exterior forces, which can efficiently manipulate the agreement of the roadbed. For example, in smooth soil foundations, the shear electricity of the soil is especially low, and the agreement hassle is extra prominent. After laying geogrid material, the shear electricity of the tender soil can be appreciably improved, thereby lowering the contract of the road.

The Application Logic of Geogrid Material in Different Road Scenarios

The anti-settling common sense of geogrid material will exhibit specific traits in one-of-a-kind street scenarios, and its utility strategies and consequences are additionally different.

In the building of new roads, geogrid material is normally laid in the roadbed. For roadbeds with negative soil quality, such as cohesive soil or sandy soil with low bearing capacity, laying geogrid can successfully enhance the bearing ability of the roadbed. During the development process, the geogrid is positioned between one of a kind soil layers, which can forestall the mixing of specific soil layers and hold the integrity of the soil structure. At the identical time, it can disperse the load from the pavement to a deeper soil layer, lowering the stress on the underlying soil and consequently lowering settlement.

In the reconstruction and enlargement of ancient roads, contract regularly happens at the junction of the historical and new roadbeds, which is basically due to the distinction in compaction diploma and bearing ability between the ancient and new soils. Geogrid material can play a suitable position in connecting and transitioning here. By laying geogrid at the junction, the stress at the junction can be evenly distributed, decreasing the distinction in contract between the historical and new roadbeds, and heading off the prevalence of cracks and uneven agreement at the junction.

For roads with heavy visitors loads, such as highways and industrial roads, the necessities for anti-settling are higher. Geogrid material with greater tensile power and modulus is commonly chosen in these scenarios. It can face up to the repeated motion of heavy loads, decrease the cumulative deformation of the roadbed, and make certain the long-term steadiness of the road. In addition, in these avenue projects, a couple of layers of geogrid material are once in a while laid to structure a multi-layer reinforcement system, which similarly enhances the anti-settling effect.

The Construction Technology of Geogrid Material: Ensuring the Anti-Settling Effect

The anti-settling impact of geogrid material in avenue engineering is additionally intently associated to its building technology. Only with the aid of making sure the scientific and lifelike building can the overall performance of the geogrid be absolutely exerted.

First, the laying of geogrid material have to be flat and free of wrinkles. If there are wrinkles, the stress on the geogrid will be uneven at some point of use, which will have an effect on its anti-settling impact and even purpose the geogrid to break. Therefore, for the duration of construction, it is vital to pull the geogrid tightly and repair it firmly.

Second, the overlapping size of geogrid material ought to meet the diagram requirements. Generally, the overlapping size is 10-30 cm. Sufficient overlapping size can make certain the integrity of the geogrid system, stop stress awareness at the joint, and keep away from contract triggered by means of the failure of the joint.

In addition, the backfilling of soil after laying the geogrid is additionally crucial. The backfill soil have to be compacted in layers, and the compaction diploma have to meet the diagram standards. If the compaction is now not sufficient, the soil will have giant voids, and agreement will effortlessly take place beneath the motion of exterior loads, which will have an effect on the anti-settling impact of the geogrid. At the identical time, throughout the backfilling process, it is essential to keep away from destructive the geogrid, such as stopping sharp objects from piercing the geogrid.

The Advantages of Geogrid Material in Anti-Settling Compared with Traditional Materials

Compared with ordinary anti-settling substances such as gravel bedding and cement soil, geogrid material has apparent blessings in anti-settling.

In phrases of cloth performance, geogrid material has greater tensile electricity and higher durability. Traditional substances such as gravel bedding are effortlessly affected with the aid of environmental elements such as water and temperature, ensuing in decreased overall performance over time. Geogrid material, on the other hand, has true corrosion resistance, growing older resistance, and temperature resistance, and can preserve steady overall performance for a lengthy time in a range of harsh environments, making sure the long-term anti-settling impact of the road.

In phrases of building efficiency, the building of geogrid material is extra handy and fast. Traditional substances frequently require a lot of transportation and on-site mixing, which is time-consuming and labor-intensive. Geogrid material is mild in weight, handy to transport and lay, and can notably shorten the development period, decreasing the have an effect on of building on traffic.

In phrases of financial benefits, even though the preliminary funding of geogrid material may additionally be greater than that of regular materials, thinking about its lengthy carrier lifestyles and low preservation cost, its complete monetary advantages are greater significant. Traditional substances regularly want to be repaired and changed regularly due to negative anti-settling effect, which will increase the usual price of the project.

Conclusion

In avenue engineering, the anti-settling good judgment of geogrid material is a complete end result of its structural characteristics, interplay with soil, software in distinctive scenarios, and scientific development technology. Its special grid structure, excessive tensile strength, and appropriate interplay with soil allow it to successfully disperse stress, prevent soil displacement, and enhance the bearing capability of the roadbed, thereby enjoying an vital position in resisting settlement.

With the non-stop improvement of avenue engineering technology, geogrid material will be always accelerated and optimized, and its anti-settling overall performance will be similarly enhanced. In the future, it is believed that geogrid material will be extra broadly used in avenue engineering, making higher contributions to enhancing the first-rate and carrier existence of roads.