Roof Water Storage And Drainage Board

Manufacturing Process

Polymer granule drying and material blending

Injection molding or thermoforming using precision steel molds

Controlled cooling to stabilize panel geometry

Automated trimming and dimensional calibration

In-line load testing for compressive performance

Surface quality inspection and stacking

Labeling, lot tracking, and protective pallet packaging

Product Definition

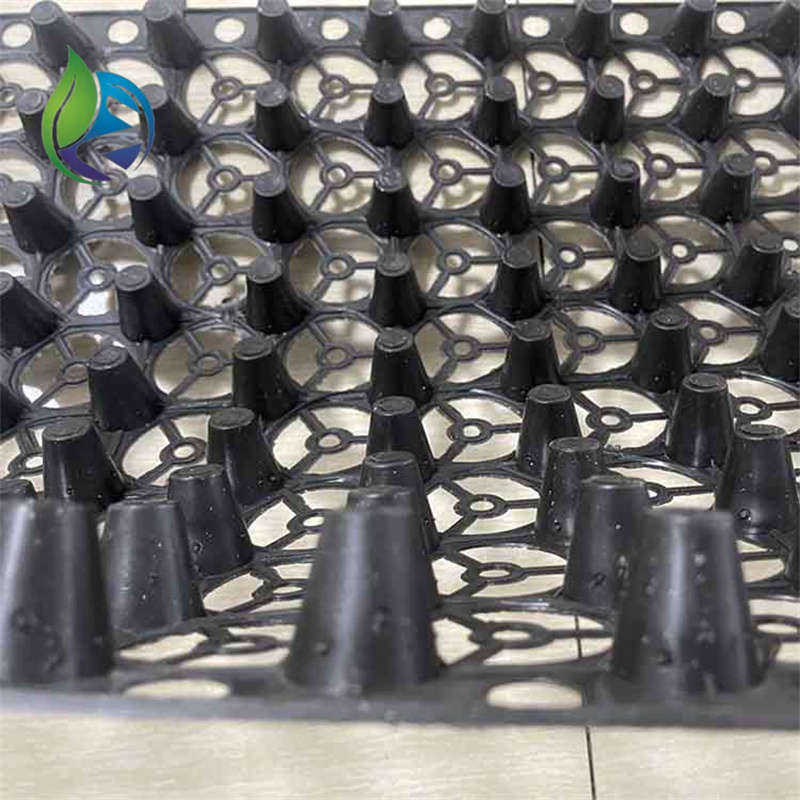

Roof Water Storage And Drainage Board is a modular plastic panel system designed for rooftop rainwater retention, delayed discharge, and horizontal drainage. It creates controlled water storage voids while maintaining structural stability, protecting waterproofing layers and improving roof hydrological performance.

Technical Parameters and Specifications

Base material: HDPE or recycled polypropylene (PP)

Standard thickness: 20 mm, 25 mm, 30 mm, 40 mm, 50 mm

Water storage capacity: 8–30 L/m² (model dependent)

Compressive strength: 150–500 kN/m²

Vertical load resistance: ≥200 kN/m² (short-term)

Drainage flow rate: ≥15 L/(m·s)

Operating temperature range: -30°C to +80°C

Panel size: 500 × 500 mm or 500 × 1000 mm

Connection type: Interlocking edge or snap-fit system

Structure and Material Composition

Top support plate with distributed load ribs

High-void conical or columnar water storage cups

Integrated lateral drainage channels

Bottom support grid for load transfer

Anti-aging polymer base with UV stabilizers

Optional filter fabric lamination interface

Manufacturing Process

Polymer granule drying and material blending

Injection molding or thermoforming using precision steel molds

Controlled cooling to stabilize panel geometry

Automated trimming and dimensional calibration

In-line load testing for compressive performance

Surface quality inspection and stacking

Labeling, lot tracking, and protective pallet packaging

Industry Comparison

| System Type | Water Retention Capacity | Drainage Efficiency | Structural Load Capacity | Service Life |

|---|---|---|---|---|

| Roof Water Storage And Drainage Board | High | High | High | 25–40 years |

| Gravel Drainage Layer | Low | Medium | Medium | 10–15 years |

| Foam Drainage Panels | Medium | Low | Low | 8–12 years |

| Expanded Clay Aggregate | Medium | Medium | Medium | 10–20 years |

Application Scenarios

Green roofs and rooftop gardens for real estate developers

Commercial podium decks for EPC project contractors

Industrial plant roofs requiring flood mitigation

Rainwater harvesting systems for institutional buildings

Urban sponge city roof infrastructure projects

Core Pain Points and Engineering Solutions

Excess roof load: Hollow structural design reduces dead load while maintaining strength.

Ponding water: Integrated drainage channels ensure rapid horizontal water movement.

Clogging risk: Compatible filter fabric interfaces prevent fine particle blockage.

Waterproofing damage: Smooth bottom surface protects membrane layers.

Risk Warnings and Mitigation Measures

Risk of improper slope design – ensure minimum roof gradient of 2%.

Risk of overload from heavy landscaping – verify compressive class before selection.

Risk of UV degradation during storage – keep panels covered before installation.

Risk of joint separation – use compatible interlocking systems during assembly.

Procurement and Selection Guide

Confirm structural roof load capacity with the project engineer.

Calculate required water retention volume per square meter.

Select panel height based on drainage and storage design goals.

Verify material type for fire and environmental regulations.

Request compressive strength and creep test reports.

Evaluate installation complexity and labor availability.

Check compatibility with waterproofing and root barrier systems.

Engineering Case Example

In a commercial office complex, Roof Water Storage And Drainage Board panels with a 30 mm profile were installed over 12,000 m². The system achieved a designed retention capacity of 18 L/m² while maintaining stable drainage during peak rainfall exceeding regional stormwater discharge limits.

FAQ

Q1: What is the primary role of Roof Water Storage And Drainage Board?

A: To store and control rooftop rainwater while providing drainage.

Q2: Can it be used directly on waterproof membranes?

A: Yes, with appropriate protection layers.

Q3: Is it suitable for green roof systems?

A: Yes, it is widely used in vegetated roofing.

Q4: How is drainage capacity calculated?

A: Based on panel geometry and hydraulic test results.

Q5: What materials are typically used?

A: HDPE or polypropylene polymers.

Q6: What is the maximum service temperature?

A: Typically up to +80°C.

Q7: Does it support pedestrian loads?

A: Yes, when specified with sufficient compressive strength.

Q8: Can panels be cut on site?

A: Yes, using standard construction tools.

Q9: Is additional geotextile required?

A: Recommended in soil-based green roof systems.

Q10: How long is the service life?

A: Typically 25–40 years under standard conditions.

Call to Action (CTA)

For project-specific quotations, technical datasheets, drainage calculations, or engineering samples of Roof Water Storage And Drainage Board, submit detailed roof drawings and load requirements for technical assessment.

E-E-A-T Author Credentials

This technical content is prepared by a building drainage and geosynthetic systems engineer with over 15 years of experience supporting EPC contractors, developers, and infrastructure consultants in large-scale commercial and industrial roofing projects.