Drainage board for Roof Gardens

Manufacturing Process

Drainage board for roof gardens is produced through controlled industrial processes:

Polymer resin selection and formulation

Thermoforming or extrusion molding of drainage sheets

Precision forming of dimples or channel structures

Cooling and dimensional stabilization

Optional geotextile lamination

Inline inspection for thickness and strength

Roll or panel cutting and packaging

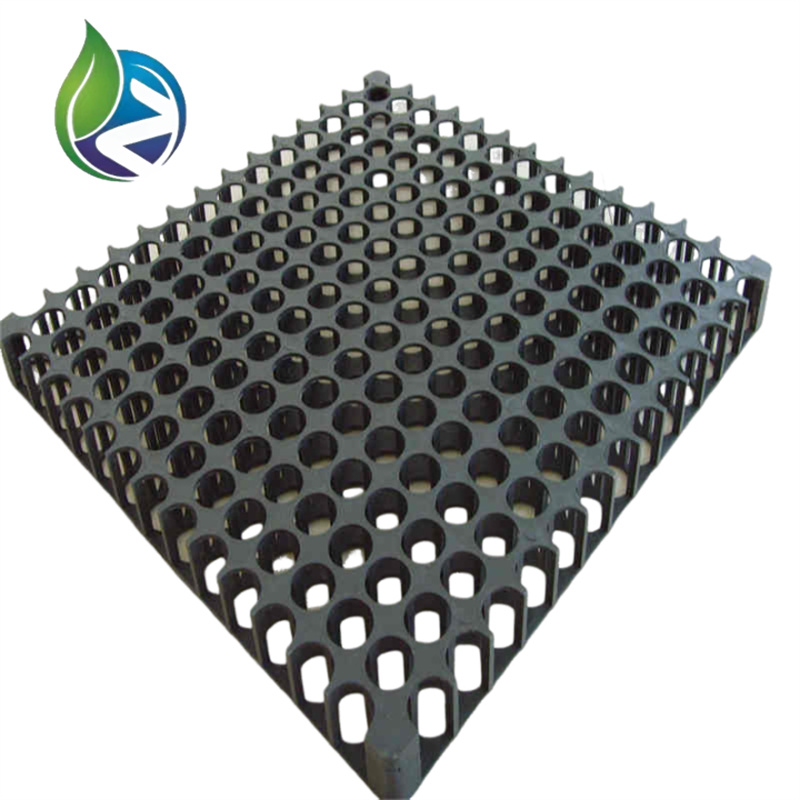

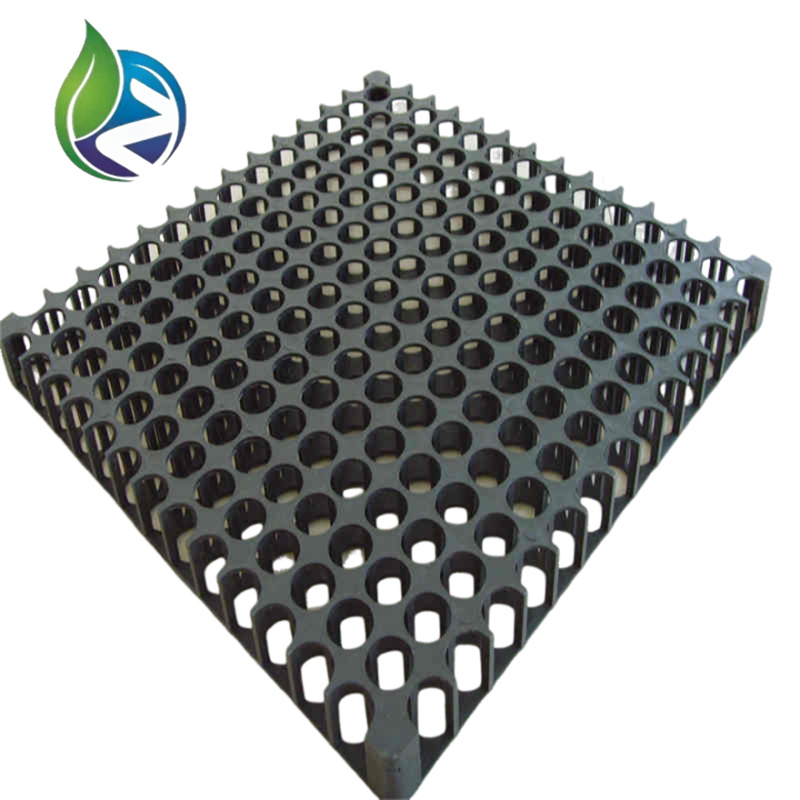

Product Definition

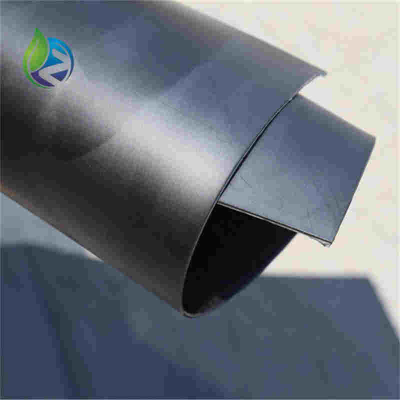

Drainage board for roof gardens is a high-strength polymer-based drainage layer installed above waterproofing systems to efficiently discharge excess water, protect structural slabs, and create stable growing conditions for vegetation in green roof and rooftop landscape projects.

Technical Parameters and Specifications

The following parameters are commonly specified in commercial and municipal roof garden projects:

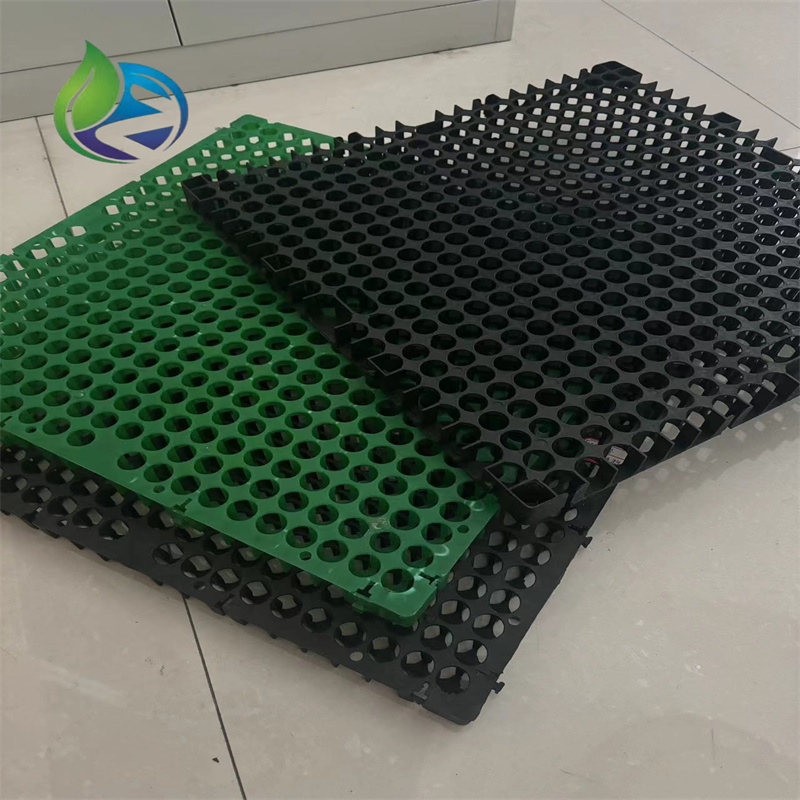

Board thickness: 8 mm – 30 mm

Compressive strength: ≥ 150 kPa (10% deformation)

Material: High-density polyethylene (HDPE) or polypropylene (PP)

Drainage capacity: ≥ 8.0 L/(m·s)

Surface load resistance: ≥ 400 kN/m² (with soil cover)

Operating temperature range: -30°C to +70°C

Design service life: ≥ 25 years

Structure and Material Composition

The functional performance of drainage board for roof gardens depends on its engineered layered structure:

Upper Support Layer: Raised dimples supporting soil and landscape loads

Drainage Channel Layer: Interconnected cavities enabling horizontal water flow

Base Protection Layer: Continuous sheet protecting waterproof membranes

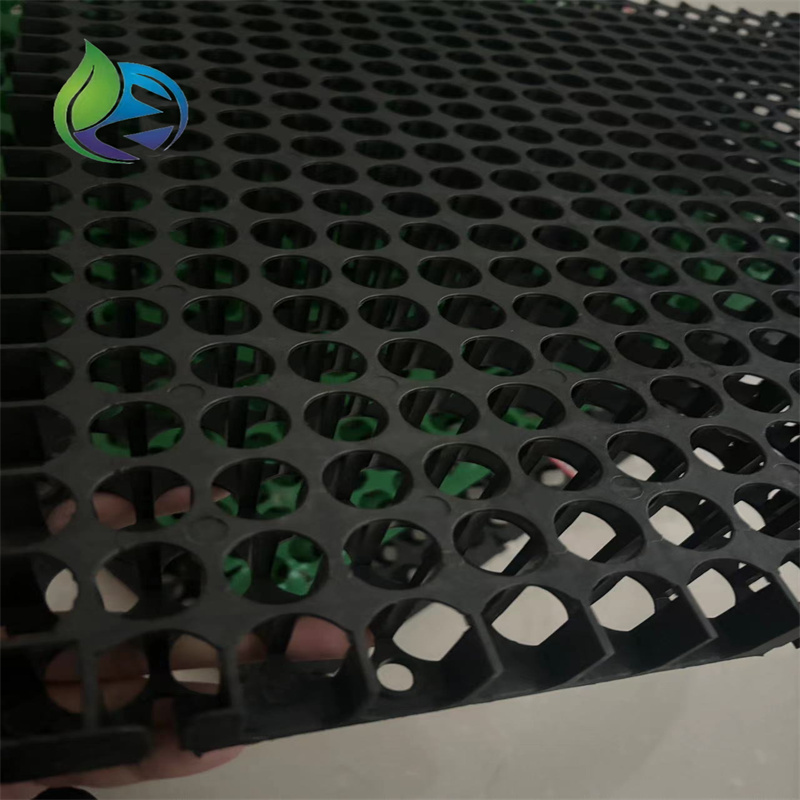

Optional Filter Layer: Nonwoven geotextile preventing soil particle blockage

Material Additives: Anti-aging agents and UV stabilizers

Manufacturing Process

Drainage board for roof gardens is produced through controlled industrial processes:

Polymer resin selection and formulation

Thermoforming or extrusion molding of drainage sheets

Precision forming of dimples or channel structures

Cooling and dimensional stabilization

Optional geotextile lamination

Inline inspection for thickness and strength

Roll or panel cutting and packaging

Industry Comparison

| Drainage Method | Drainage Efficiency | Structural Protection | Service Life | Maintenance Requirement |

|---|---|---|---|---|

| Drainage Board | High | Excellent | 25+ years | Low |

| Gravel Layer | Medium | Limited | 10–15 years | High |

| Drainage Pipes | Localized | Moderate | 15–20 years | Medium |

| Sand Bed | Low | Poor | 5–8 years | High |

Application Scenarios

Drainage board for roof gardens is widely specified by:

Commercial building developers

EPC contractors for green roof systems

Municipal infrastructure and public buildings

Residential and mixed-use rooftop landscapes

Industrial facilities with roof greening requirements

Core Pain Points and Solutions

Pain Point: Water accumulation causing root rot

Solution: Continuous horizontal drainage channelsPain Point: Waterproof layer damage under load

Solution: Load-distributing dimple structurePain Point: Soil clogging drainage paths

Solution: Integrated geotextile filtrationPain Point: Long-term maintenance costs

Solution: Durable polymer materials with long service life

Risk Warnings and Mitigation

Key risks and preventive measures include:

Improper overlap: maintain minimum 100 mm board overlap

Insufficient slope: ensure roof slope ≥ 2%

Point load concentration: apply protection boards where required

Filter layer omission: always use geotextile in soil-based systems

Procurement and Selection Guide

Confirm roof load-bearing capacity

Determine required drainage capacity

Select appropriate board thickness

Verify compatibility with waterproofing system

Check compressive strength certifications

Request laboratory test reports

Evaluate supplier production consistency

Engineering Case Study

In a commercial office roof garden project, a 20 mm drainage board for roof gardens was installed beneath 300 mm of planting soil. After two years of operation, no water retention issues were observed, and waterproof membrane inspections showed no mechanical damage.

FAQ

What is the main function of drainage board? Efficient water discharge and structural protection.

Is geotextile always required? Yes, for soil-based roof gardens.

Can it be used on flat roofs? Yes, with proper slope design.

Does it replace waterproofing? No, it protects waterproof layers.

What thickness is commonly used? 10–20 mm for most projects.

Is it resistant to root penetration? Yes, when properly specified.

Can boards be cut on site? Yes, using standard tools.

What is the typical roll or panel size? Commonly 2 m width or modular panels.

How long is the service life? Typically over 25 years.

Is testing required before installation? Recommended for large-scale projects.

Call to Action

To request pricing, technical datasheets, or engineering samples of drainage board for roof gardens, please contact our technical sales department with your project requirements.

E-E-A-T Author Statement

This article is prepared by building envelope and green roof engineering specialists with over 15 years of experience in roof drainage systems, waterproof protection, and landscape infrastructure projects.