A Brief Discussion on the Construction Plan of HDPE Composite Geotextile for Channel Anti-seepage River Management

Product Definition

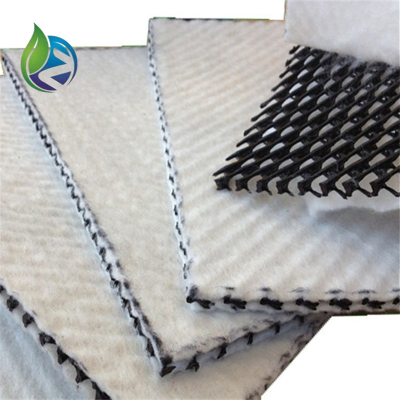

HDPE composite geotextile is an engineered anti-seepage material combining an HDPE geomembrane with nonwoven geotextiles. It is widely used in channel lining and river management projects to control seepage, improve structural stability, and enhance long-term hydraulic and environmental performance.

Technical Parameters and Specifications

The construction plan for HDPE composite geotextile must be based on standardized technical parameters to ensure hydraulic safety and durability.

Geomembrane material: High Density Polyethylene (HDPE)

Geotextile material: Polypropylene (PP) nonwoven

Total thickness: 0.8–2.0 mm (HDPE layer)

Geotextile mass: 200–600 g/m² (single or double-sided)

Tensile strength: ≥15 MPa (HDPE)

Elongation at break: ≥500%

Hydrostatic pressure resistance: ≥0.6 MPa

Seam strength: ≥80% of parent material

Operating temperature range: -40°C to +60°C

Structure and Material Composition

HDPE composite geotextiles are multilayer systems designed to integrate impermeability and mechanical protection.

Upper protective geotextile layer: Reduces puncture and construction damage

Central HDPE geomembrane: Primary anti-seepage barrier

Lower geotextile layer: Enhances friction and subgrade compatibility

Thermal bonding interface: Ensures long-term layer integrity

Manufacturing Process

Engineering-Oriented Production Steps

HDPE resin melting and flat-die extrusion into geomembrane sheets

Nonwoven geotextile production via needle-punching lines

Thermal lamination of geotextile and geomembrane layers

Cooling, surface inspection, and thickness calibration

Roll cutting, labeling, and quality testing

Core equipment: Extrusion lines, needle looms, laminating machines, ultrasonic thickness gauges, tensile testers.

Key process controls: Bond strength uniformity, membrane thickness tolerance, and surface cleanliness.

Industry Comparison

| Material Type | Anti-Seepage Performance | Mechanical Protection | Construction Efficiency | Service Life |

|---|---|---|---|---|

| HDPE Composite Geotextile | Very High | High | High | 30–50 years |

| Single HDPE Geomembrane | High | Low | Medium | 25–40 years |

| Concrete Lining | Medium | Very High | Low | 40–60 years |

| Clay Lining | Low–Medium | Low | Low | Variable |

Application Scenarios

HDPE composite geotextile construction plans are widely adopted in hydraulic and environmental engineering.

Irrigation channels: Seepage control and water conservation

River regulation works: Bank protection and leakage prevention

Flood control channels: Structural stability under fluctuating water levels

EPC projects: Integrated hydraulic infrastructure delivery

Core Pain Points and Engineering Solutions

Seepage-induced soil erosion: Continuous HDPE membrane ensures impermeability

Construction damage risk: Composite geotextile provides puncture resistance

Uneven subgrade settlement: Flexible lining adapts to deformation

High maintenance costs: Long service life reduces lifecycle expenditure

Risk Warnings and Mitigation Strategies

Improper subgrade preparation may cause stress concentration

Unqualified welding can lead to leakage paths

Extended UV exposure before backfilling may reduce performance

Inadequate anchoring increases uplift risk

Procurement and Selection Guide

Confirm hydraulic design requirements and seepage control standards

Determine membrane thickness based on water pressure

Select appropriate geotextile weight for protection needs

Specify welding and seam testing requirements

Verify compliance with ASTM / EN / ISO standards

Assess supplier quality assurance and project references

Plan installation sequencing and site logistics

Engineering Case Example

In a regional irrigation channel rehabilitation project, a 1.5 mm HDPE composite geotextile with double-sided 400 g/m² nonwoven layers was installed along a 6 km channel. The construction plan included staged subgrade leveling, membrane welding, vacuum seam testing, and soil cover placement. Post-completion monitoring showed significant reduction in seepage losses and improved channel stability.

FAQ

What is the main role of HDPE composite geotextile? Channel anti-seepage and structural protection.

Is it suitable for high groundwater levels? Yes, with proper anchoring design.

How are seams tested? Vacuum box or air pressure testing.

Can it replace concrete lining? In many projects, yes.

What thickness is commonly used? 1.0–1.5 mm for channels.

Does it resist chemical exposure? HDPE offers strong chemical resistance.

How long is the service life? Typically 30–50 years.

Is installation weather-sensitive? Yes, extreme temperatures should be avoided.

Can it handle subgrade settlement? Yes, due to flexibility.

Is third-party testing recommended? Strongly recommended for EPC projects.

CTA

For detailed construction specifications, engineering drawings, or project-based quotations for HDPE composite geotextile systems, please submit a formal request for technical documentation or material samples.

E-E-A-T Author Credentials

This technical discussion is authored by a civil and hydraulic engineering materials specialist with over 15 years of experience in geosynthetics applications for river management, channel lining, and large-scale water conservancy projects, supporting EPC contractors and international procurement teams.