Analysis of Application Effects and Construction Key Points of Geocells in Highway Soft Ground Treatment

Product Definition

Geocells are three-dimensional polymer grid structures used for soil confinement and load distribution in soft ground engineering. In highway construction, geocells improve bearing capacity, reduce differential settlement, and enhance long-term pavement stability by forming a reinforced composite layer with infilled soil or aggregate.

Technical Parameters and Specifications

For highway soft ground treatment, geocell performance is governed by geometric dimensions, material properties, and mechanical strength.

Cell height: 75 mm / 100 mm / 150 mm / 200 mm

Cell size (expanded): 300–450 mm

Material: HDPE or PP (UV-stabilized)

Tensile strength at yield: ≥ 20 MPa

Seam peel strength: ≥ 10 kN/m

Thickness: 1.2–1.8 mm

Design service life: ≥ 50 years (buried conditions)

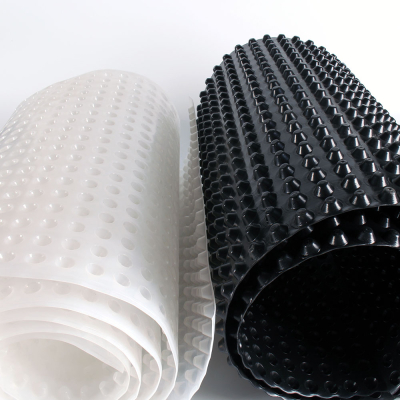

Structure and Material Composition

Geocells used in highway soft ground treatment consist of interconnected polymer strips welded ultrasonically to form a honeycomb structure.

Cell walls: High-density polyethylene with controlled elongation

Weld joints: Ultrasonic welds ensuring shear resistance

Perforations (optional): Improve drainage and soil interlock

Infill materials: Sand, crushed stone, graded gravel, or stabilized soil

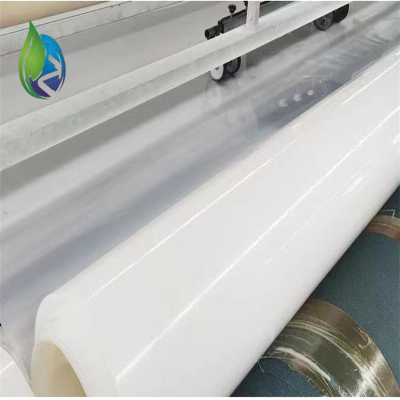

Manufacturing Process

Industrial production of highway-grade geocells follows standardized, quality-controlled steps.

Polymer compounding with anti-aging and UV additives

Sheet extrusion with thickness tolerance control

Precision punching (for perforated designs)

Ultrasonic welding to form cell arrays

Dimensional inspection and tensile testing

Factory expansion testing and packaging

Industry Comparison

| Solution | Load Distribution | Construction Speed | Material Cost | Suitability for Soft Ground |

|---|---|---|---|---|

| Geocells | High (3D confinement) | Fast | Medium | Excellent |

| Geogrids | Medium (2D reinforcement) | Fast | Low | Moderate |

| Stone replacement | High | Slow | High | Good |

| Pile-supported embankment | Very High | Slow | Very High | Excellent |

Application Scenarios

Geocells are widely applied in highway engineering projects involving weak or compressible subgrades.

Expressway embankments over soft clay

Highway widening projects with differential settlement risk

Temporary access roads on saturated soils

Service roads and shoulders in marshland areas

Bridge approach transition sections

Core Engineering Pain Points and Solutions

Low bearing capacity: Geocell confinement increases composite modulus

Excessive settlement: Load dispersion reduces stress concentration

Lateral soil displacement: 3D grid restrains horizontal movement

High construction cost: Reduced fill thickness lowers material volume

Risk Warnings and Mitigation Measures

Risk of inadequate anchorage on slopes → Use U-shaped steel pins

Improper infill gradation → Follow project-specific gradation design

UV exposure during storage → Cover and limit exposure time

Uneven subgrade preparation → Ensure compaction uniformity before installation

Procurement and Selection Guide

Confirm soil bearing capacity and design load

Select appropriate cell height based on deformation control needs

Verify material certification and mechanical test reports

Match perforation design to drainage requirements

Assess supplier welding strength consistency

Request project references in highway soft ground treatment

Engineering Case Example

In a coastal highway project with soft clay subgrade (cu = 18–25 kPa), a 150 mm high geocell layer infilled with graded crushed stone was installed beneath the base course. Plate load tests showed a bearing capacity increase of over 2.3 times, while post-construction settlement was reduced by approximately 40% compared to untreated sections.

FAQ

Q1: Are geocells suitable for very soft clay?

A: Yes, when combined with proper infill and separation layers.Q2: Can geocells replace piling?

A: In moderate loads, yes; heavy loads may still require piles.Q3: What is the typical installation speed?

A: 1,500–3,000 m² per day per crew.Q4: Do geocells require maintenance?

A: No maintenance when buried properly.Q5: Are geocells environmentally safe?

A: Yes, inert polymers with long-term stability.Q6: Can local soil be used as infill?

A: If gradation and strength meet design requirements.Q7: What standards apply?

A: ASTM, ISO, and regional highway specifications.Q8: How is quality checked on site?

A: Visual inspection and weld peel testing.Q9: Are geocells reusable?

A: Generally no, intended for permanent works.Q10: What is the design lifespan?

A: Typically over 50 years in buried conditions.

Call to Action

For project-specific design support, technical datasheets, or material samples for highway soft ground treatment, please submit your engineering requirements to request a detailed quotation and technical proposal.

E-E-A-T Author Credentials

This article is authored by a geotechnical engineering specialist with over 15 years of experience in highway subgrade reinforcement, soil stabilization systems, and polymer geosynthetics. The content reflects practical EPC project knowledge and internationally recognized engineering standards.