Grass grid paving takes on a new look, meeting both greening and hardening standards

Grass Pavers Plastic Renovate Pavement Surfaces, Achieving Dual Standards of Greening and Hardening

Steady development in urban building and garden greening always brings one common problem. Pavement hardening and ecological greening often clash, and this issue never gets fully fixed without the right materials and methods. Cities need tough, long-lasting pavement for foot traffic, cars and daily use. They also want to keep as much green space as possible, to make the local ecology better, stop soil from washing away and lift up the overall environmental quality of the area. This need for both practical use and eco-friendliness pushes builders to look for better pavement materials and laying ways. These days, building material tech has stepped up, and people care more about real ecological building work too. A new pavement material has spread fast across different construction jobs. It fills the gap between hard pavement build and green space needs perfectly. It meets strict hardness and load-bearing rules for paved ground, and it also keeps as much live green grass as possible on site. This material is what truly makes pavement renewal work look and perform better in every way.

The Core Requirement of Modern Pavement Construction: Greening and Hardening Both Matter

For years, a lot of construction projects got stuck in one wrong thought. People thought pavement hardening and ecological greening had to be two separate things. If you wanted a tough, wear-proof hard pavement, you had to cut down most green vegetation. If you wanted to keep a good green coverage rate, you had to scale back hard paving—and that left the ground easy to damage, unable to hold heavy weight at all. This problem pops up in every kind of construction site. It’s seen in residential parking lots, sidewalks and green belts, as well as municipal roads, slope protection work and park square building. Builders and users alike want one thing: pavement that’s solid enough to last, and still keeps the eco-friendly green benefits the land needs. This strong market need drives better pavement material designs forward, and grass pavers plastic came into use right for this reason. It quickly became a top pick for both old pavement renewal and new construction projects all around.

Greening isn’t just planting a few grasses and plants on the ground. It’s a key part of real ecological building. Green cover soaks up dust, cleans the air, holds soil and water in place, and softens the urban heat island effect too. All these bring lasting eco benefits to the whole area. Hardening is the basic need for usable pavement. It makes sure people and cars move smoothly, stops the ground from turning muddy and broken, and cuts down on repair costs later on. These two goals don’t have to fight each other. They just need to be balanced well together. Modern pavement build works best when it gets both right at the same time. And that’s exactly what a good quality pavement material should deliver for every project.

The Unique Advantages of Grass Pavers Plastic in Pavement Renovation Work

grass pavers plastic didn’t become popular in pavement and greening work by chance. It’s popular because it has real, practical strengths—strengths that fit the green and hard pavement needs of modern building work perfectly. Just first, on hardening performance: plastic grass pavers are made from high-density engineering plastic, formed with high heat and full pressing. The whole structure is solid and firm, with strong pressure resistance. It holds up well under regular cars, heavy trucks and even construction machines. Pavement laid with these pavers won’t warp, crack or sink, even under years of constant weight. This level of durability matches traditional cement and asphalt pavement fully. It hits all the basic hardness rules for every type of paved ground out there.

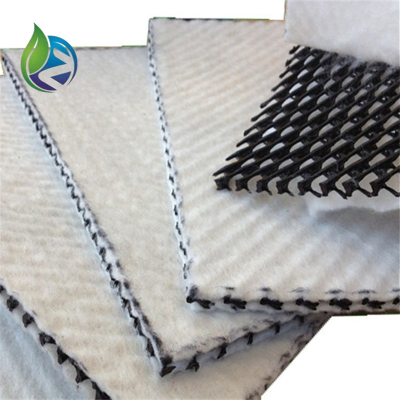

And also, the design of grass pavers plastic lines up perfectly with ecological greening needs. Unlike solid traditional hard pavement, plastic grass pavers have hollow grid shapes in different sizes. You fill these hollow grids with nutrient soil and grass seeds. After a short time of basic care, green grass grows right through the gaps of the pavers. Grass roots grip the soil and the paver structure tight, making a thick green layer on top of the hard pavement. This design changes pavement for good. It’s no longer just a plain hard surface. It becomes a green hard pavement, mixing plant life with strong building material. It keeps the pavement usable for all normal needs, and brings back the green coverage of the ground too. This is how real integration of hard paving and ecological greening actually happens.

What’s more, plastic grass pavers are light, easy to work with and simple to lay down. Compared with heavy cement bricks and stone slabs, these plastic pavers are easier to transport and carry to the site. You don’t need complex machines or super skilled workers to lay them either. Regular construction teams can finish the laying work fast, following basic standard steps. This cuts down the whole build time a lot, and saves on labor and material costs for the project. For old pavement renewal, this plus point is even clearer. You can lay these pavers right over the old ground, no big demolition or rebuild needed. This means construction work has almost no impact on how the area is used day to day, and no big disturbance to the surrounding environment either.

Grass Pavers Plastic Adapt to All Kinds of Construction Scenarios with Strong Compatibility

grass pavers plastic is widely used in pavement renewal work mainly because it fits so many different environments and build sites. It’s not a material that only works for one single job. It can be used flexibly for nearly all construction projects that need both green cover and hard pavement. It works well in every different setting, and brings consistent use performance and eco benefits each time.

In residential communities, plastic grass pavers are the top choice for parking lots, fire lanes and neighborhood walkways. Parking lots laid with these pavers hold up to all types of car weight easily. The grass growing in the gaps also cuts down car driving noise and harsh sunlight reflection, making the whole neighborhood feel quieter and more comfortable. Fire lanes with this material meet all hard pavement fire safety rules, and add more green space to the community too—making residential areas look greener and nicer overall. For municipal garden projects, plastic grass pavers go into park squares, scenic trails and green belt dividers. They let tourists walk around smoothly, and keep the garden’s green landscape intact too. It all blends human activity with natural green space in a gentle way.

Even more, grass pavers plastic is irreplaceable for slope protection and soil fixing work—like road edges, river banks and hillside projects. The hollow grid structure of these pavers locks soil on slopes tight, stopping rainwater from washing soil away and causing erosion. Grass roots growing in the grids hold the soil structure even firmer, creating a double layer of protection: paver plus live grass. This eco-friendly slope protection works better and lasts longer than traditional cement slope work. It also brings green grass back to slopes, and fits perfectly with the simple idea of eco protection and green building. No matter if it’s flat ground build or slope engineering, plastic grass pavers perform well and fit right in. They’ve become a must-have material for real modern ecological construction work.

Long-term Use Value of Grass Pavers Plastic: Low Maintenance Cost and Durable Greening Effect

For any construction material, short-term performance counts—but long service life and low upkeep costs make the real difference to a project’s overall value. grass pavers plastic excels right here. Its long-term advantages make this material even more practical. It also makes the dual goals of greening and hardening stable and long-lasting, not just a quick surface fix for a project inspection.

In terms of material durability, good quality plastic grass pavers are made with anti-aging and anti-corrosion engineering plastic. They stand up to rain, sun, extreme heat and cold for years on end. They don’t fade, get brittle or warp from natural weather changes. Qualified plastic grass pavers last more than ten years easily—way longer than regular cement bricks and grass mats. When it comes to later maintenance, plastic grass pavers are a breeze too. The grass in the grids only needs regular watering and simple trimming, no fancy care steps required. The pavers themselves hardly get damaged at all. Even if one or two pieces break, you can replace them fast and simple, no big repair work or full rebuild needed. This low maintenance cost makes plastic grass paver pavement great value over time. It also makes sure the pavement keeps its hard strength and green look for years, no extra hassle added.

The best part is, the green effect from grass pavers plastic is real and long-lasting eco greenery. Grass growing through the pavers is live natural vegetation. It soaks up carbon dioxide and releases oxygen, softens the small local climate of the area, and even gives small insects and microbes a good place to live. This creates a tiny natural cycle right on the pavement surface. This kind of eco value is way more than what artificial turf can offer. It’s also a real reflection of modern building ideas: green development first, and eco care as a priority. Hard pavement with lasting green grass meets people’s daily life and work needs, and makes cities and rural areas nicer and more livable places to be.

Grass Pavers Plastic Create a New Pattern of Ecological Pavement with Greening and Hardening Dual Compliance

At its core, grass pavers plastic changes pavement renewal work because it breaks the old divide between greening and hardening. With smart material design and simple structural innovation, it unites these two key needs perfectly. For a long time, construction projects had to pick one: too much hard paving meant lost green space, too much green meant damaged pavement. Neither choice met real construction and use needs. Now, with plastic grass pavers being used more widely, this old problem is gone for good.

Pavement renewed with grass pavers plastic meets all national and industry hard pavement standards fully. It has enough load-bearing power, solid structure, and wears well under pressure—meeting all needs for people and vehicle movement. At the same time, the green grass coverage on this pavement hits all relevant green construction rules. It even adds more green space while keeping the hard pavement strong. This means construction projects pass hard pavement checks easily, and score well on greening standards too. This is the real meaning of greening and hardening dual compliance. It’s also why pavement renewal work truly looks and functions like a whole new space.

People care more and more about real ecological civilization construction these days. The need for green, eco-friendly pavement materials will only grow, and construction projects will keep raising the bar for balancing greening and hardening together. grass pavers plastic fits this trend perfectly, so it will surely be used more widely in urban and rural building, garden greening, slope protection and more. It’s not just a simple upgrade to pavement materials. It’s proof that construction ideas have shifted—from just focusing on practical use, to making eco care and practicality work side by side.

Pavement renewal is a small detail, but it ties right into building a fully green and ecological city. Every small choice in material and construction method makes a difference. Grass pavers plastic prove that hard pavement build and ecological greening can exist together well, and support each other too. Pavement that’s hard, strong and covered in green grass is more than just a nice sight in cities and towns. It’s a solid base for steady eco construction development. As plastic grass paver tech keeps getting better and more refined, it will keep making pavement and greening work better too. It will keep building a better future for ecological pavement—one that always hits both greening and hardening standards, no compromises needed.