Gathering strength to prevent seepage and lay a solid foundation, high-quality geomembranes safeguard engineering construction

Solidifying Anti-seepage Foundations, High-quality Geomembranes Escort Engineering Construction

In modern civil engineering and infrastructure development, project stability and long-term durability are always the core focus of all construction work. For all large and medium engineering projects, anti-seepage and waterproof protection is never just a simple auxiliary step. It is a basic part that directly decides a project’s overall service life, operational safety and long-term use effect. From water conservancy projects, reservoir building and sewage treatment systems, to landfill anti-seepage, road base reinforcement and ecological restoration work, effective anti-seepage measures are necessary to keep engineering foundations firm and stable. Driven by this strong industry demand, high-quality geomembrane materials have slowly become the top choice for engineering anti-seepage work. Their irreplaceable role in construction keeps showing more clearly in real application. Good anti-seepage work builds the base for solid engineering projects, and reliable geomembrane products are what make this solid base possible. Picking qualified, high-performance geomembranes can stop quality issues like water seepage and soil erosion from happening later on. It also cuts down on repair and renovation costs after a project finishes, and truly turns engineering projects into sturdy, long-lasting infrastructure with strong stability and anti-risk ability.

The Irreplaceable Status of Anti-seepage Work in Modern Engineering Construction

Engineering construction is always a systematic job that needs strict attention to every small detail, and anti-seepage protection is a key part that runs through the whole construction process and can never be overlooked. For most engineering projects – underground construction, water conservancy facilities and environmental protection projects included – seepage problems will bring a chain of bad results right away. Softened soil structure, foundation settlement, corroded and aged concrete structure, even structural damage and project failure in serious situations. These problems do not just make follow-up maintenance more expensive, they also affect a project’s normal use and core functions. Worse still, they bring hidden safety risks to the nearby environment and people’s daily production and living. As engineering construction standards keep getting higher, and the industry cares more about project quality and safety, the need for professional, effective anti-seepage materials keeps growing year after year. The market also asks more from anti-seepage materials in terms of performance, quality and practical use. In this trend, hdpe black smooth geomembrane has become a mainstream anti-seepage material trusted by the whole engineering industry. It relies on steady physical performance and outstanding anti-seepage effects, and now acts as a key material for building strong anti-seepage barriers in all kinds of engineering projects. Building a solid foundation is the core of engineering construction, and anti-seepage work is the first defense line to make this foundation firm. Only with good anti-seepage protection can engineering structures stay stable, and real project quality be guaranteed.

Core Characteristics of High-quality Geomembranes for Engineering Anti-seepage Applications

Geomembranes are impermeable membrane materials made from polymer synthetic materials through special processing and forming. Their main function is to stop water flow from penetrating, and prevent soil and liquid medium loss. The quality of geomembrane products directly impacts a project’s anti-seepage effect, so choosing high-quality geomembrane materials is a very important decision in the whole construction process. Most high-quality geomembranes on the market use high-density polyethylene as the main raw material. With reasonable formula and strict production control, the finished products have even thickness, smooth surfaces, strong tensile strength and good flexibility. Unlike cheap, low-quality geomembranes, high-quality ones can keep stable performance in different construction environments and climate conditions. They do not crack or deform easily, nor age fast. They form a full, tight anti-seepage layer on construction surfaces, and provide long-lasting, effective anti-seepage protection. More importantly, high-quality geomembranes resist chemical corrosion well. They can stand the erosion of acid, alkali, salt and other chemical media in soil and water, and fit well in all kinds of complex engineering scenes – from fresh water conservancy projects to industrial waste treatment sites. Among high-quality geomembrane products, hdpe black smooth geomembrane stands out with better material structure and surface design. Its smooth surface does not stick to impurities and soil easily, making construction laying and later cleaning maintenance much easier. Its black raw material formula also has better anti-ultraviolet performance, which slows down aging damage from long-time sun exposure, and extends the anti-seepage layer’s service life further. For engineering construction, these stable, reliable geomembrane materials are the best choice for building solid anti-seepage foundations, and the core support for raising overall project quality.

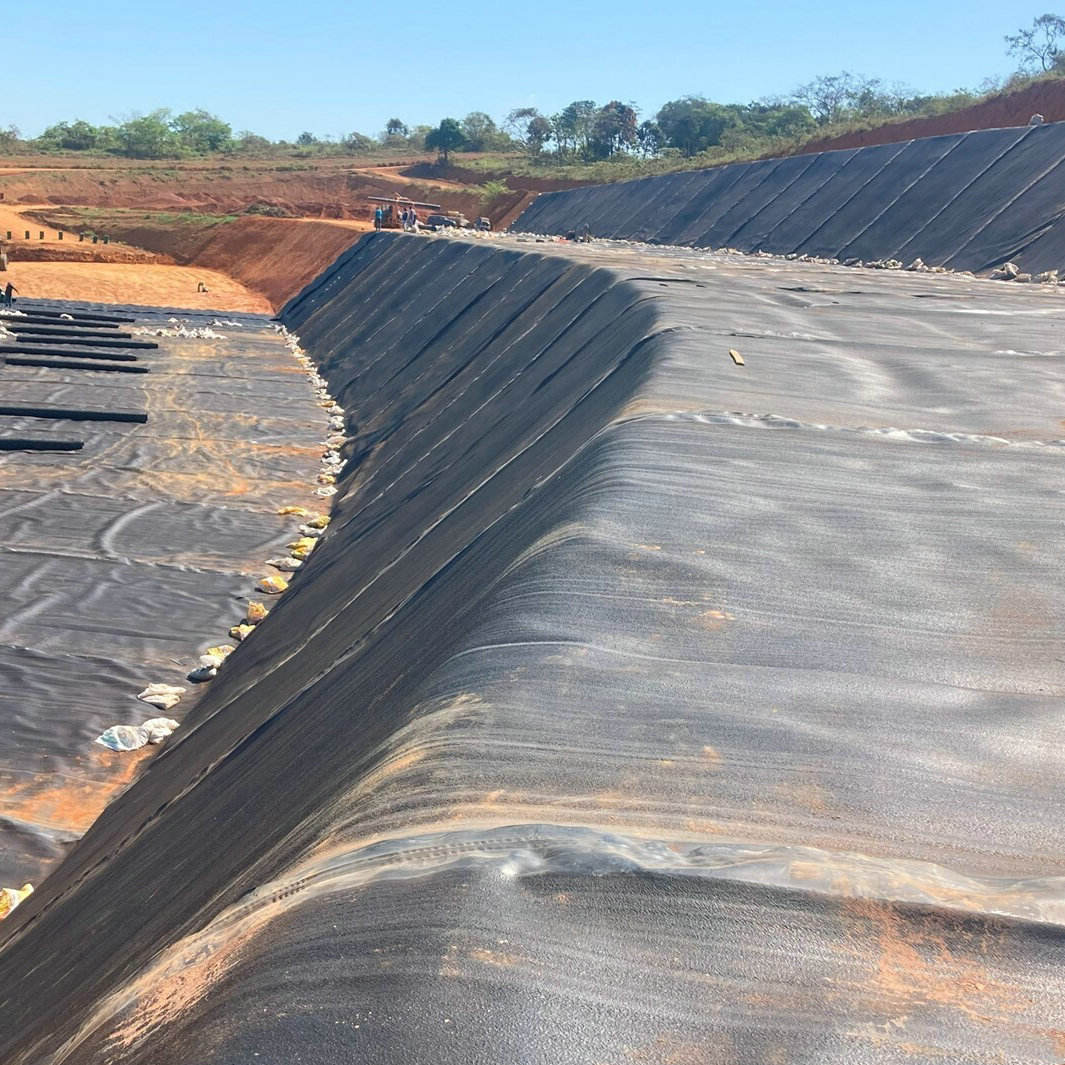

How High-quality Geomembranes Build a Solid Anti-seepage Foundation for Engineering Projects

The real value of high-quality geomembranes shows in their practical use in engineering construction, and their ability to combine with project structures to form effective anti-seepage defense lines. Geomembrane laying and construction go hand in hand with the whole project schedule, and laying quality directly decides the final anti-seepage result. High-quality geomembrane materials have good ductility and toughness, so they fit well with uneven construction base surfaces. They can be laid tightly against the base with no gaps left, which stops water seepage from joint areas. In construction, professional laying skills and proper joint treatment match with high-quality geomembranes perfectly. Together they form seamless, whole anti-seepage membrane surfaces, and block all possible seepage channels of a project from the root. This tight, reliable anti-seepage protection is what keeps projects stable for a long time, and it is why more construction teams choose high-quality geomembranes as their core anti-seepage material now. Instead of only chasing low costs, the engineering industry focuses more on material cost performance and long-term use value now. Choosing high-quality geomembranes may add a little to the initial purchase cost, but it saves a lot of follow-up maintenance fees caused by seepage problems. It also ensures normal project operation and avoids safety accidents. In this process, hdpe black smooth geomembrane becomes a reliable choice for many projects.

It ensures good anti-seepage performance, and is also easy to lay and construct. Its smooth surface reduces friction during laying, speeds up construction progress, and the tight bonding effect after laying raises the whole project’s anti-seepage quality. It really achieves the goal of building solid anti-seepage foundations with high-quality materials.

The Adaptability of Premium Geomembranes to Diverse Engineering Anti-seepage Demands

Modern engineering construction covers many different types of projects. Different projects have different environmental features and anti-seepage needs, which means geomembrane materials need to meet various performance and applicability requirements. Water conservancy projects like reservoirs, canals and dams need geomembranes that resist high water pressure and long-time immersion well. Landfill and sewage treatment projects need geomembranes with strong chemical corrosion resistance, to block harmful chemical substances from penetrating. Ecological restoration and slope protection projects need flexible, eco-friendly geomembranes that adapt to natural soil settlement and deformation. Facing these different engineering needs, high-quality geomembrane materials show strong adaptability and compatibility. They can be adjusted and optimized based on different project features, to meet the personalized anti-seepage needs of all kinds of projects. Geomembrane production technology improves all the time with engineering industry development, product specifications and performance indexes get better and better, and they can cover anti-seepage needs of all project types – from small civil construction to large national key infrastructure projects. High-quality geomembranes are not rigid, single-type products. They are flexible, adjustable anti-seepage solutions that match different engineering scenes well. Among these various geomembrane products, hdpe black smooth geomembrane becomes a universal anti-seepage material in the industry for its balanced performance and wide applicability. It can be used in most engineering anti-seepage scenes: water conservancy, environmental protection, road construction and ecological restoration all included. It plays a stable, effective anti-seepage role in all these fields, and its consistent quality and performance make it a trusted choice for construction parties. This wide adaptability not only proves the high quality of geomembrane products, but also makes high-quality geomembranes a necessary part of all kinds of engineering projects, and keeps escorting the construction and operation of different engineering projects.

Long-term Durability and Sustainable Development Value of High-quality Anti-seepage Geomembranes

Now the whole industry advocates green construction and sustainable engineering development. Besides basic performance, long-term durability and eco-friendliness have become important standards to evaluate building materials. For geomembranes used in engineering anti-seepage, long-term durability means the anti-seepage layer can keep stable performance for a long time under natural environment and project use. No frequent replacement or maintenance is needed, which cuts down later project operation costs, and also reduces environmental impact from material replacement and construction waste. High-quality geomembranes are made of high-grade polymer raw materials with strict production control. They have excellent anti-aging, anti-ultraviolet and anti-corrosion performance, their service life matches well with a project’s designed service life, and they realize long-term anti-seepage protection for engineering projects.

At the same time, high-quality geomembranes are produced with eco-friendly concepts. Raw materials are non-toxic and harmless, no harmful substances are released to soil and water during use. All these meet the eco-friendly requirements of modern engineering construction, and fit the green, low-carbon development concept. This sustainable application value makes high-quality geomembranes not just materials to ensure project quality, but also important support for promoting the engineering industry’s sustainable development. In long-term anti-seepage applications, hdpe black smooth geomembrane has obvious advantages. Its black polyethylene material resists ultraviolet radiation strongly, slowing down membrane aging from long outdoor exposure effectively. Its smooth surface does not gather dirt and moss easily, reducing damage from external factors, and extending the anti-seepage layer’s service life further. This long durability makes the anti-seepage foundation built by high-quality geomembranes more solid, and brings more stable, long-term use guarantees for engineering projects. It is a clear reflection of geomembrane materials’ sustainable development value in engineering construction.

Concluding Remarks

Engineering construction is all about solidity and durability, every construction step has a close connection with the final project quality and safety. As the foundation of project stability, anti-seepage protection always has an irreplaceable important position in the whole construction process. High-quality geomembrane materials are the core carrier to achieve effective anti-seepage protection. From raw material selection to production control, from construction laying matching to engineering scene adaptation, high-quality geomembranes keep improving their performance and quality in every aspect. They have become an important material for building solid anti-seepage foundations in modern engineering construction. The engineering industry keeps developing towards higher standards and better quality, and the demand for anti-seepage materials keeps upgrading too. High-quality geomembrane materials represented by hdpe black smooth geomembrane will keep up with the industry development, optimize performance constantly and expand application scope, always standing in the front line of engineering anti-seepage protection.

Building a solid anti-seepage foundation is the first step to build high-quality engineering projects, and high-quality geomembranes are the reliable guarantee for this step. In the future development of engineering construction, high-quality geomembrane materials will keep playing their core anti-seepage role. With stable performance and reliable quality, they will keep escorting all kinds of engineering construction, build solid anti-seepage defense lines for every project, and contribute to the long-term stability and sustainable development of the whole engineering industry. All engineering construction stands on solid foundations, and reliable anti-seepage protection is the cornerstone of all solid foundations. With high-quality geomembranes, engineering projects can stand firm and develop steadily for a long time.