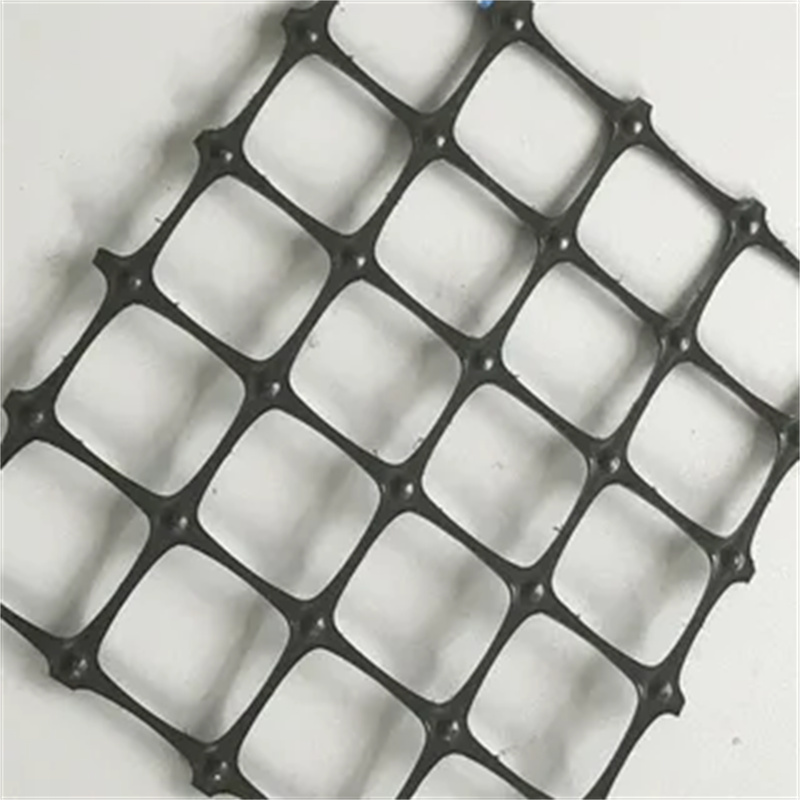

Biaxial Polypropylene Geogrid

The bidirectional plastic stretch geogate is made of high polymer through extrusion. plate forming, punching process and then longitudinal and transverse stretching. The material has great tensile strength in both longitudinal and transverse aspects, and this structure can also provide an ideal interlocking system for more effective force bearing and diffusion in the soil. which is suitable for the reinforcement of large areas of permanent load.

When it comes to ensuring long-term structural stability in roads, railways, and embankments, biaxial tensile plastic geogrids for foundation reinforcement have become an industry game-changer. These engineered materials are designed to dramatically improve soil bearing capacity, minimize settlement, and extend the lifespan of infrastructure projects. If you’re looking for a reliable, cost-effective way to reinforce soft soil foundations, biaxial tensile plastic geogrids for foundation reinforcement offer unmatched performance.

What Are Biaxial Tensile Plastic Geogrids?

Biaxial tensile plastic geogrids are high-strength polymer grid structures manufactured from polypropylene (PP) or high-density polyethylene (HDPE). The key feature is their equal strength in both longitudinal and transverse directions, allowing them to distribute loads uniformly across a foundation surface.

In foundation engineering, biaxial tensile plastic geogrids for foundation reinforcement provide a high level of stiffness and interlocking performance, making them ideal for reinforcing subgrades and base courses under roads, pavements, platforms, and retaining structures.

Why Choose Biaxial Tensile Plastic Geogrids for Foundation Reinforcement?

1. Superior Load Distribution

One of the core benefits of using biaxial tensile plastic geogrids for foundation reinforcement is their ability to spread applied loads over a wide area, reducing localized stress on subgrade soils. This minimizes rutting and structural deformation over time.

2. Exceptional Soil Stabilization

These geogrids interlock with aggregates to confine the material and reduce lateral displacement. The result? Increased foundation stiffness and lower differential settlement.

3. High Durability & Corrosion Resistance

Manufactured with UV-stabilized polymers, biaxial tensile plastic geogrids resist chemical degradation, making them suitable for challenging environments like landfills, wastewater treatment plants, and acidic soils.

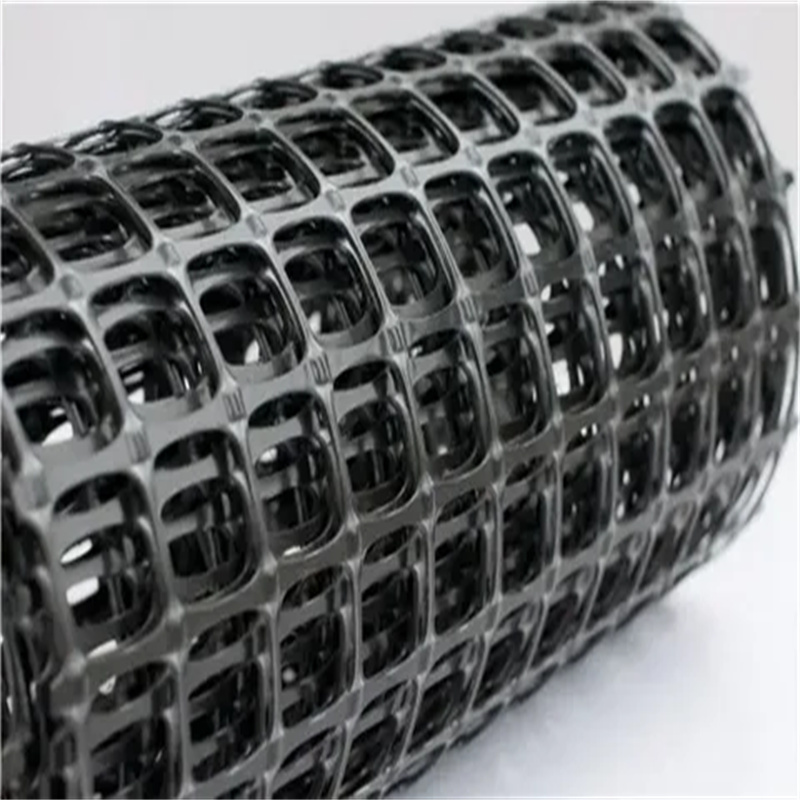

4. Easy and Fast Installation

Compared to traditional soil reinforcement methods, biaxial tensile plastic geogrids for foundation reinforcement are lightweight and easy to handle. This reduces labor costs and shortens construction schedules.

Key Applications of Biaxial Tensile Plastic Geogrids

Road and highway base reinforcement

Railway trackbed stabilization

Airport runway foundation

Retaining wall and slope support

Warehouse and parking lot ground reinforcement

Temporary access roads in soft soil areas

Wherever weak subgrades threaten stability, biaxial tensile plastic geogrids for foundation reinforcement provide a reliable, cost-effective solution.

How to Install Biaxial Tensile Plastic Geogrids for Foundation Reinforcement

Prepare the Foundation: Clear debris and level the subgrade.

Roll Out the Geogrid: Lay the geogrid flat without wrinkles, with overlap at joints.

Anchor and Secure: Use U-pins or fill material to fix the geogrid in place.

Place the Aggregate: Fill and compact layers as specified.

Continue Construction: Proceed with road surfacing or structure building.

Tip: Always follow the manufacturer’s guidelines for overlap length, fill depth, and compaction procedures to maximize the effect of biaxial tensile plastic geogrids for foundation reinforcement.

Boost Your Project’s Lifespan with Our Premium Geogrids

Looking to reinforce your foundation with confidence? Our high-performance biaxial tensile plastic geogrids for foundation reinforcement are:

✅ ISO & CE certified

✅ Available in custom widths and lengths

✅ Backed by expert engineering support

✅ Shipped globally with fast delivery

With our geogrids, you're not just buying a product — you're investing in the strength, safety, and durability of your entire project.

? Contact us now for pricing, samples, and technical consultation. Let’s reinforce your foundation the smart way with biaxial tensile plastic geogrids for foundation reinforcement.

Final Thoughts

In modern civil engineering, no other material offers the combined benefits of stability, cost-efficiency, and ease of use like biaxial tensile plastic geogrids for foundation reinforcement. Whether you're working on road construction, railway stabilization, or site development, geogrids are your go-to solution for lasting results.

Key Features and Properties

High Tensile Strength in Two Directions: Unlike uniaxial geogrids, biaxial geogrids provide equal reinforcement in both horizontal directions, making them ideal for stabilizing weak soils.

Superior Load Distribution: Reduces differential settlement by evenly distributing loads over a larger area.

Chemical and UV Resistance: Resistant to chemicals, biological degradation, and ultraviolet (UV) exposure, ensuring durability in harsh environmental conditions.

Lightweight and Easy to Install: The geogrid’s structure allows for quick installation, reducing labor and material costs.

Improved Drainage: The open grid structure facilitates water drainage, preventing soil erosion and water accumulation.

Long-Term Performance: Provides lasting reinforcement, reducing maintenance and repair costs over time.