Technical Iteration of Geotextiles Empowers Low-Carbon Transformation of Infrastructure

Geotextile Technology Iteration: Empowering Low-Carbon Transformation in Infrastructure

The world’s pretty serious about cutting carbon lately, building more sustainable infrastructure right along. Demand for materials that balance performance, durability, environmental responsibility? Hasn’t been this high in years. Geotextiles have long been solid workhorses in construction and civil engineering—folks in the industry know, they’ve seen some major tech upgrades lately. No longer just basic protective fabrics, they’re high-performance, eco-friendly solutions now, driving low-carbon changes across roads, railways, water conservancy and ecological restoration projects. These upgrades don’t just make projects stronger; they shift how the industry thinks about sustainability too, y’know what I mean. Turns out, building infrastructure and caring for the environment can actually work hand in hand.

The Evolution of Geotextile Materials: From Durability to Eco-Friendliness

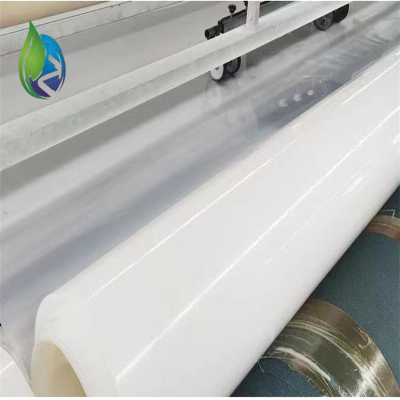

Geotextiles have come a long way since their early days—basic woven or non-woven fabrics, mostly used for separating soil and controlling erosion. Today’s versions? Years of R&D went into these things, focusing on two main things: boosting performance to cut long-term maintenance, and using eco-friendly materials to shrink carbon footprints. One of the biggest shifts? Ditching traditional petroleum-based materials—ones that pile up plastic waste and crank up greenhouse gas emissions—for recycled and biodegradable fibers.Material choices, let’s be real, play a huge part in this shift. Manufacturers are doubling down hard lately on recycled polyester from plastic bottles, reclaimed nylon—even natural fibers like jute and coconut coir. These geotextiles keep their strength, no doubt, but they’re way gentler on the planet. They don’t just keep waste out of landfills; they use less energy to make than new ones too. Recycled polyester geotextiles, for one, cut carbon emissions by up to 70% during production compared to those made with virgin petroleum-based polyester. This shift lines up with global pushes to make the construction supply chain more circular—turning waste into something useful instead of just tossing it out.Better material engineering helps too, real plus that is. It’s made geotextiles tougher against UV rays, chemical wear, mechanical strain—all the tough conditions you see on job sites. Modern geotextiles hold up against harsh weather, heavy loads, even long-term exposure to soil and water—they don’t break down, not for ages. That makes infrastructure last longer, so fewer replacements over time. This durability directly supports low-carbon goals, ‘cause it cuts down on the energy and materials needed for maintenance and reconstruction. Geotextile waterproofing? Stepped up big time lately. Advanced coatings and fiber blends make barriers that work better, last longer—slashing the risk of water damage that usually leads to carbon-heavy repairs.

How Geotextile Tech Drives Low-Carbon Infrastructure Practices

Advanced geotextiles’ low-carbon benefits aren’t just about how they’re made. Infrastructure projects—how they’re designed, built, run—all that changes with these geotextiles too. One clear change: using less material. Geotextiles act as reinforcement, separation and filtration layers, so engineers can use less concrete, asphalt and aggregate. Those materials take a ton of energy to extract, transport and process. In road construction, geotextile-reinforced base layers can cut the required thickness of asphalt or concrete by up to 30%. That saves on material costs, and cuts down on the carbon released when making those materials too.Geotextiles also make construction smoother, cutting down on on-site energy use. Traditional infrastructure projects usually involve a lot of digging, hauling and compacting—jobs that rely on heavy machinery burning fossil fuels. Using geotextiles to stabilize soil, improve drainage, and prevent erosion lets contractors dial back these operations. Take slope stabilization: geotextile mats mean no more massive concrete retaining walls, period. Instead, you use lightweight, easy-to-install fabrics. You need fewer trucks to transport them, less heavy equipment to set up. This not only speeds up construction but cuts diesel use and on-site emissions too—simple as that.Water management’s another area geotextiles help with low-carbon goals—and geotextile waterproofing’s a big piece of that. Good water control cuts the energy needed for pumping, treatment, and flood prevention—simple but effective. Geotextile waterproofing membranes go into landfills to stop leachate contamination, for one thing. They’re also used in reservoirs to reduce water seepage, so less energy-heavy water replenishment is needed. In urban infrastructure, permeable geotextiles help manage stormwater by letting water soak into the soil. That eases the load on municipal drainage systems that use a lot of energy, and lowers the risk of floods needing costly, carbon-heavy recovery work too. Geotextile waterproofing also stops water damage to structures—that means fewer repairs, and repairs almost always use materials and processes that emit a lot of carbon.

Expanding Applications: Geotextiles in Modern Infrastructure Projects

Advanced geotextiles are cropping up in new uses across all infrastructure sectors—and every time, they bring low-carbon benefits to projects that used to be total resource guzzlers. In transportation, they’re a staple in road and railway projects these days. They reinforce subgrades, separate different soil layers and improve drainage. This not only makes roads and railways last longer, but lets engineers use local, lower-quality soils too.

That cuts down on the need to transport aggregates from faraway quarries—a major source of carbon emissions in construction.In water conservancy projects, geotextiles are used for riverbank protection, dam reinforcement and wetland restoration. They can stop erosion while letting water and nutrients seep through, making them perfect for ecological restoration. They support plant growth and wildlife habitats without disrupting natural processes. Unlike concrete or rock armoring, geotextile erosion control mats blend right into the environment. They boost biodiversity while cutting the carbon footprint of river and coastal protection projects. Geotextile waterproofing’s especially useful here, in dam and reservoir projects. It provides a reliable barrier against water seepage without the environmental harm of traditional concrete liners.Geotextiles play a key role in renewable energy infrastructure too. Solar farms need stable, erosion-free ground to support solar panels—geotextile mats stabilize the soil, stop weed growth and improve drainage, all while letting rainwater soak in and support local ecosystems. Wind farms use geotextiles as well—in access roads and turbine foundations. They cut down on soil compaction and erosion, keeping the environmental impact of these projects low. By making renewable energy infrastructure more sustainable to build, geotextiles indirectly cut carbon emissions from fossil fuel power generation.Even in urban development, geotextiles are doing their part to make cities greener. They’re used in green roofs to improve drainage and soil stability, in permeable pavements to manage stormwater, and in urban landscaping to prevent erosion in parks and green spaces. These uses not only reduce the urban heat island effect but lower the carbon footprint of city construction too. They cut down on the need for concrete and other high-emission materials.

Meeting Global Low-Carbon Standards: The Industry Impact of Geotextile Innovation

Countries worldwide are rolling out stricter carbon reduction targets these days. Initiatives like the Paris Agreement and 2050 net-zero goals mean construction firms and infrastructure developers face more pressure than ever to adopt sustainable practices. Advanced geotextiles have emerged as a cost-effective solution—they help meet these standards without sacrificing performance. Many governments and international groups now see geotextiles as a key material for low-carbon infrastructure, offering incentives for projects using eco-friendly geotextile solutions.The growth of the sustainable geotextile market’s driving even more innovation these days. Manufacturers are sinking money into research to develop even greener materials. Fully biodegradable geotextiles for temporary uses, like construction site erosion control—these break down naturally after use, no waste left behind. Others are focusing on making geotextiles more recyclable, creating closed-loop systems where old geotextiles get collected and turned into new materials. These small tweaks not only shrink geotextiles’ environmental footprint, but make them more appealing to companies wanting to boost their sustainability credentials too.Geotextile innovation’s fostering more collaboration across the industry too.

Engineers, material scientists and construction companies are teaming up—designing projects that maximize the potential of advanced geotextiles, from initial planning to long-term maintenance. This collaborative approach leads to more efficient, sustainable infrastructure solutions that set new standards for low-carbon development. It creates a blueprint for future infrastructure projects, using geotextile strengths to cut emissions and boost durability.Geotextile waterproofing has become a benchmark for sustainable water management in infrastructure. As regulators tighten standards for water conservation and pollution prevention, geotextile waterproofing solutions offer a compliant, low-carbon alternative to traditional methods. Their ability to cut water waste, stop contamination and reduce maintenance needs makes them a key part of projects looking to meet green building certifications like LEED or BREEAM.

Conclusion

Geotextile technology has come a long way from its simple beginnings—it’s now a cornerstone of low-carbon infrastructure development. Material innovation, better performance, more applications—all of this adds up to advanced geotextiles helping the construction industry shrink its carbon footprint. At the same time, they’re building projects that are more durable, resilient and eco-friendly. From roads and railways to water conservancy and renewable energy infrastructure, sustainability and performance don’t have to clash. You can have both, easy.The world will keep prioritizing carbon reduction in the years ahead, so the role of geotextiles will only grow. Manufacturers will keep pushing the limits on eco-friendly materials and performance. Engineers and developers will find new ways to use these solutions to meet the needs of a changing planet. Geotextile waterproofing, a key part of this innovation, will remain critical. It ensures infrastructure is protected from water damage while keeping environmental impact low.In the end, upgrading geotextile tech isn’t just about making a better building material; it’s about rethinking how we build for the long haul. Choosing advanced geotextiles lets the infrastructure industry take a real step toward reducing carbon emissions, saving resources and creating a world where development and environmental stewardship work together. As more projects embrace these innovations, geotextiles will keep empowering low-carbon transformation—laying the groundwork for a greener, more resilient planet.