Black Plastic Biaxial Geogrid

As infrastructure projects grow in complexity and scale, reinforced soil technologies are becoming essential for road construction, embankment stabilization, and foundation reinforcement. Among these solutions, black plastic biaxial geogrid has gained global attention for its strength, durability, and cost-efficient performance. This article provides a comprehensive, SEO-optimized overview for B2B buyers, including market trends, technical specifications, applications, manufacturing processes, and procurement guidelines.

Black Plastic Biaxial Geogrid: A Complete Technical Guide for Global Infrastructure Projects

As infrastructure projects grow in complexity and scale, reinforced soil technologies are becoming essential for road construction, embankment stabilization, and foundation reinforcement. Among these solutions, black plastic biaxial geogrid has gained global attention for its strength, durability, and cost-efficient performance. This article provides a comprehensive, SEO-optimized overview for B2B buyers, including market trends, technical specifications, applications, manufacturing processes, and procurement guidelines.

Growing Demand for Soil Reinforcement Materials

Global investments in transportation, mining, and urban development continue to expand, driving the demand for high-performance ground stabilization materials. According to recent industry analyses, the geosynthetics market is projected to exceed USD 20 billion by 2030, with biaxial geogrid being one of the fastest-growing categories.

Several factors contribute to the rising use of black plastic biaxial geogrid:

Need for longer-lasting pavement structures

Increasing adoption of geosynthetics in environmentally sensitive areas

Cost reduction in roadbed preparation

Rising standards for load-bearing capacity in highways and logistics routes

What Is Black Plastic Biaxial Geogrid?

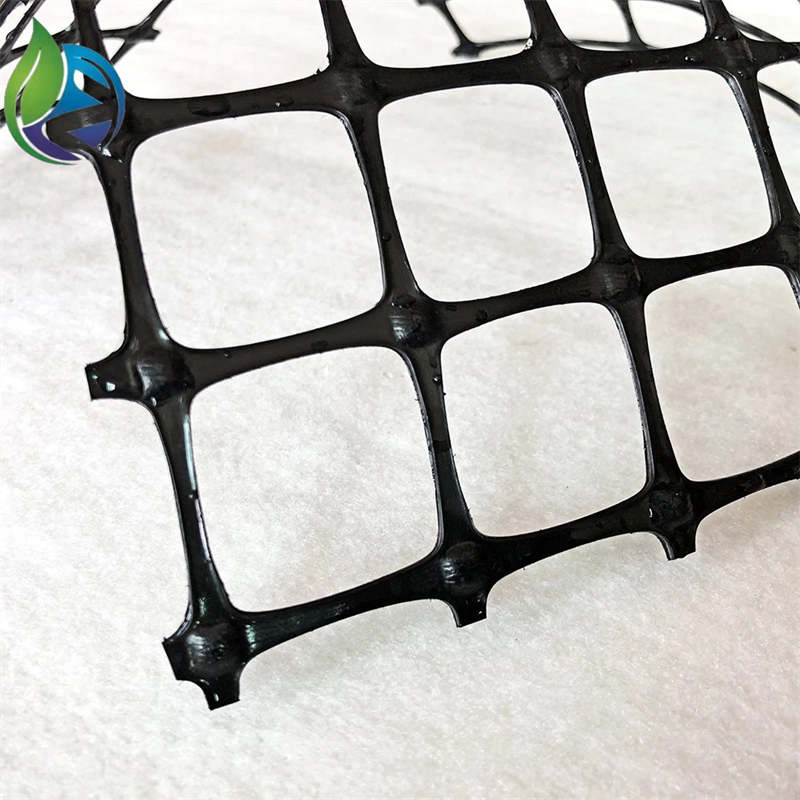

Black plastic biaxial geogrid is a polymer-based geosynthetic reinforcement material engineered with tensile strength in both longitudinal (MD) and transverse (TD) directions. This two-directional strength distribution provides superior load spreading, making it ideal for base reinforcement, subgrade improvement, and soil stabilization.

Key Characteristics

Material: Typically HDPE or PP

Structure: Stretched grid with uniform apertures

Color: Black, with UV stabilization

Strength: Balanced tensile strength in both directions

Applications: Roads, parking lots, railways, slopes, embankments, retaining walls

Its ability to lock aggregate in place significantly increases the stiffness and stability of granular layers.

Technical Advantages of Black Plastic Biaxial Geogrid

1. Improved Load Distribution

The biaxial structure enables the geogrid to disperse heavy loads across a broader area. This reduces rutting, prevents settlement, and extends pavement lifespan.

2. Enhanced Soil–Aggregate Interlock

The precise grid aperture design enhances interlock with aggregates, resulting in greater shear resistance and structural integrity.

3. Durability in Harsh Environments

Black plastic biaxial geogrid is designed to resist:

UV radiation

Chemical corrosion

Biological degradation

Freeze-thaw cycles

These features make it suitable for regions with extreme temperatures or corrosive soil conditions.

4. Reduced Base Thickness and Construction Costs

Using biaxial geogrid allows engineers to reduce aggregate thickness by up to 40% while maintaining or improving structural performance.

5. Fast Installation and Low Maintenance

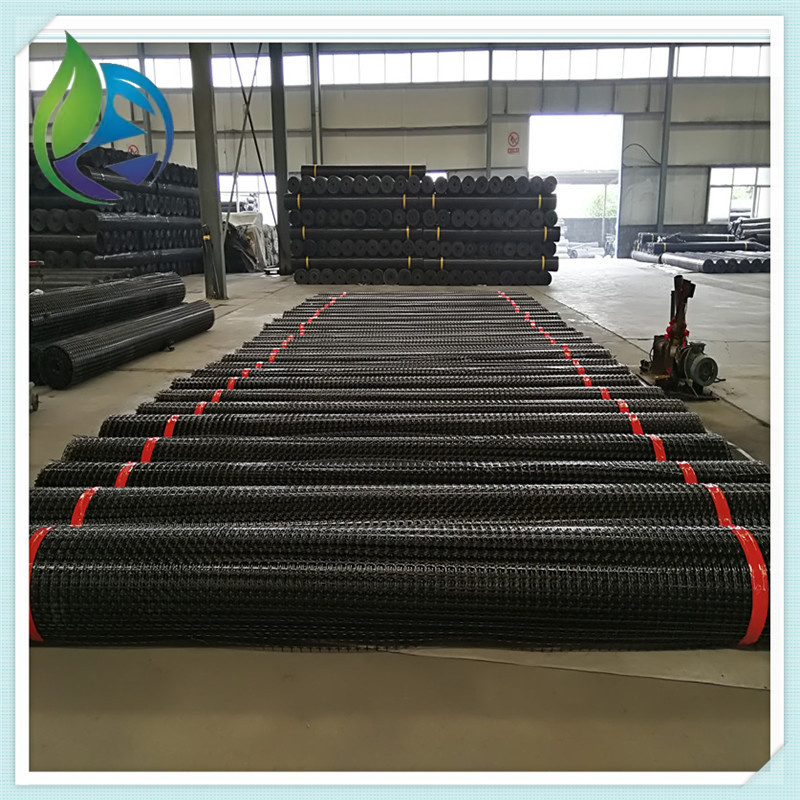

Lightweight, roll-packaged, and easy to deploy, the product saves labor time and lowers equipment requirements.

Manufacturing Process Overview

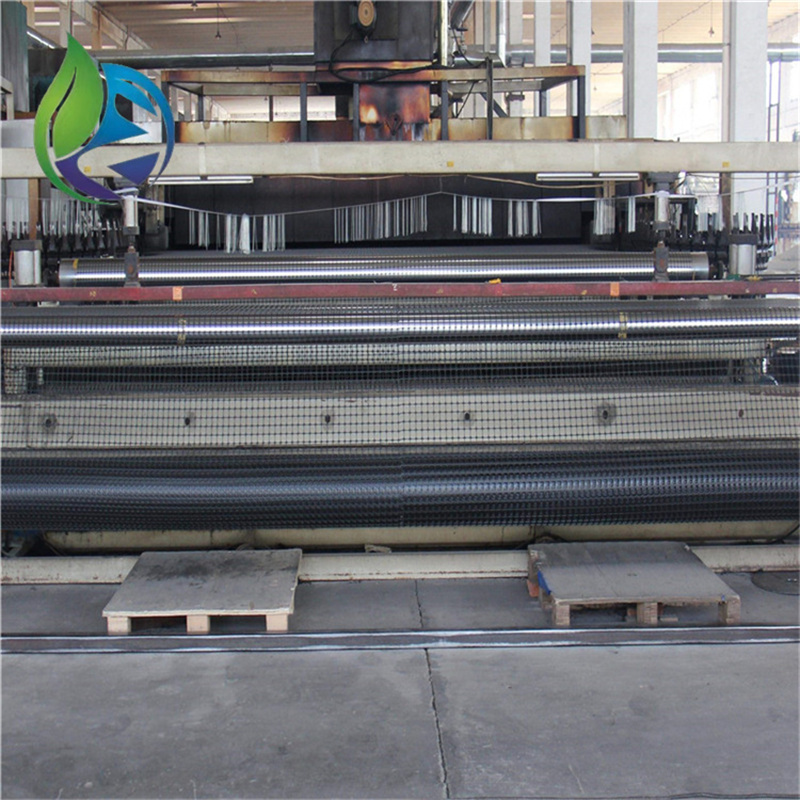

High-quality black plastic biaxial geogrid is typically produced through the following steps:

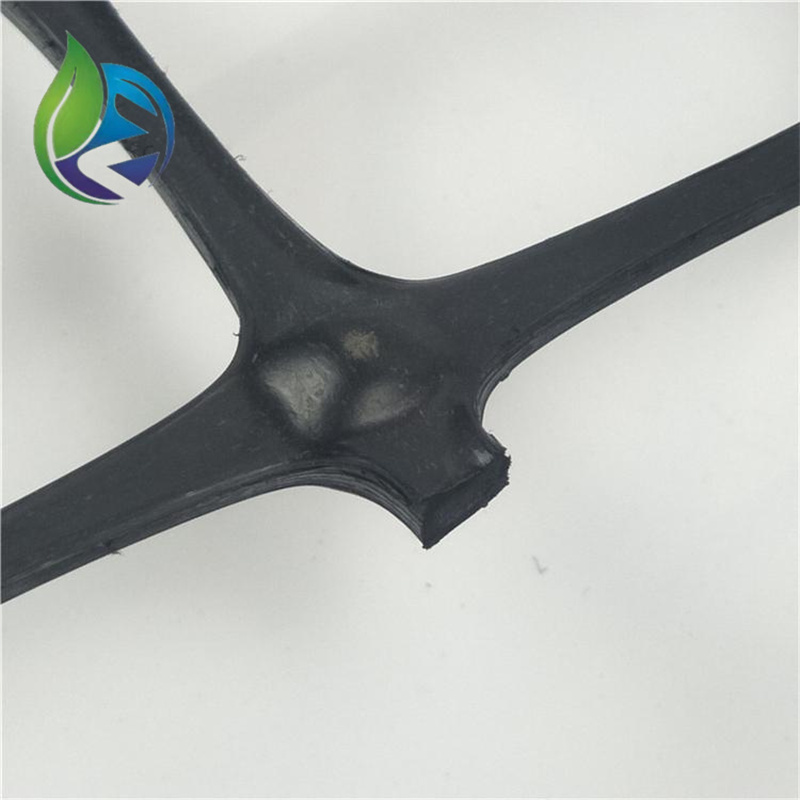

1. Extrusion

Polymer resin (HDPE or PP) is melted and extruded into a flat sheet.

2. Punching

The sheet is punched with a controlled aperture pattern.

3. Stretching

The punched sheet is stretched in both machine and transverse directions, enhancing tensile strength and molecular alignment.

4. Surface Treatment

UV stabilizers and antioxidants are added to extend outdoor service life.

5. Quality Testing

Every batch undergoes testing for:

Tensile strength (MD/TD)

Elongation

Aperture size uniformity

Chemical resistance

Durability under environmental stress

Key Applications Across Global Infrastructure

Road Construction

Black plastic biaxial geogrid is widely used in:

Highway base reinforcement

Asphalt overlay stabilization

Rural road improvement projects

Heavy-load industrial roads

Railway Subgrade

Its ability to reduce settlement and vibration helps extend the service life of railway ballast layers.

Parking Lots and Logistics Yards

The material strengthens soft soil bases and prevents deformation caused by repetitive vehicle loading.

Embankments and Slopes

By enhancing shear strength, it prevents sliding, erosion, and long-term settlement.

Retaining Wall Systems

Used as a reinforcing layer behind retaining structures to increase stability and load-bearing capacity.

Market Trends: Why Biaxial Geogrid Demand Is Growing

Increasing Infrastructure Budgets

Many developing regions are investing heavily in transportation upgrades, creating stable demand for geogrid materials.

Shift Toward Sustainable Engineering

Geogrids reduce the need for natural aggregates, supporting resource conservation and environmental compliance.

Rising Standards and Regulations

Global engineering guidelines increasingly recommend geogrid reinforcement in road and rail foundation design.

Expansion of Private Sector Construction

Industrial parks, logistics centers, and mining projects require stronger and more stable subgrade structures.

Buyer FAQs

1. How do I choose the right strength specification?

Selection depends on soil type, load requirements, and project design. Higher-strength models are recommended for heavy-duty roads, railways, and industrial floors.

2. Can black plastic biaxial geogrid be used on soft soil?

Yes. It is especially effective in stabilizing weak subgrades by improving bearing capacity and reducing settlement.

3. Is it suitable for cold or hot climates?

The product performs well across wide temperature ranges and resists freeze-thaw damage and UV exposure.

4. How long does biaxial geogrid last?

With proper installation, service life often exceeds 25 years, depending on environmental conditions and soil chemistry.

Conclusion: Why Black Plastic Biaxial Geogrid Is a Reliable Choice

From highways to industrial landscapes, black plastic biaxial geogrid offers a durable, cost-effective, and technically advanced solution for soil reinforcement. Its proven ability to enhance load distribution, reduce material consumption, and extend structural longevity makes it a preferred choice for modern infrastructure projects worldwide.

Professional Call to Action

We provide engineering-grade black plastic biaxial geogrid with consistent quality, customizable specifications, and global export support. Contact our technical team today for datasheets, design recommendations, or bulk pricing. Strengthen your next project with reliable geogrid reinforcement solutions.