A powerful tool for soil and water conservation: Geocells are widely implemented

Geocells: A Powerful Tool for Soil Erosion Control – Widely Implemented Globally

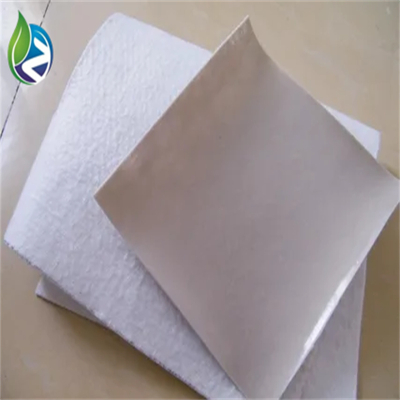

Soil erosion’s been a constant headache for infrastructure builds, environmental work, farming worldwide. Steep highway embankments, beat-up old mine sites, riverbanks, farmland—losing topsoil isn’t just hard on ecosystems. Puts buildings, roads, other key structures in real danger too. Past few years, though, a cheap, eco-friendly solution’s stepped up: geocells. These 3D honeycomb structures, mostly made from tough materials like high-density polyethylene (HDPE), have become a staple across different industry sectors. Hold soil tight, stop erosion dead in its tracks, help jumpstart ecosystem recovery. Today, geocells aren’t some niche product anymore—standard go-to for soil erosion control projects, and they’ve proven they can hold up in practically any environment or use case.

The Core Value of Geocells in Soil Erosion Control

Soil erosion happens when water, wind, or human activity washes away the topsoil layer. What’s left is dry, unstable ground—useless for growing anything, supporting structures. Traditional fixes, stuff like concrete retaining walls or rock riprap, usually costly, require lots of labor, take a heavy toll on the environment. Block natural water flow, kill any chance for plants to grow, break down over time. Geocells fix these issues by working with nature, not against it. Their honeycomb design, expanded and filled with soil, gravel, even plants sometimes on actual job sites, makes a stable, connected structure. Spreads weight evenly, boosts soil’s resistance to sliding, cuts down on surface runoff—simple, but it works.

Why do geocells work so well? Geocell specs, let’s be honest, are the real backbone. Material choice’s a big deal. HDPE’s the top pick, mostly ‘cause it stands up to UV rays, chemicals, extreme temperatures. Won’t crack or fade after years in sun and rain—holds up fine in harsh outdoor conditions. Cell size matters too. Typical dimensions 100mm to 300mm, right in the sweet spot. Soil stays put, but plants still get enough room to grow. Thicker geocell walls mean more tensile strength. Can handle heavy loads or really steep slopes without buckling. These specs aren’t random, either—engineered for specific erosion issues, so geocells adapt easy to different soil types, slope angles, on-site hurdles.

What really sets geocells apart? They stop erosion and help restore ecosystems at the same time. Unlike concrete or rock, geocells let water and air seep through to the soil—perfect for seeds to sprout, plants to take root. As those plants grow, roots wrap tighter around the soil. End up with a self-sustaining ecosystem that’s way more erosion-resistant long-term. This mix of man-made structure and natural growth makes geocells a smart pick for projects that need to be functional but gentle on the planet.

Adaptability and Construction Advantages of Geocells

One big reason geocells have gotten so popular? Adaptability. Work in practically any terrain—steep slopes, flat land, coastal areas, dry deserts. All soil types too: sandy, clay-heavy, whatever you’re dealing with. That versatility makes ‘em good for all sorts of projects: highway and railway slope protection, riverbank stabilization, landfill covers, farm terraces. Unlike rigid solutions that need super precise site prep, geocells fit right into uneven, bumpy surfaces. No need for tons of digging or grading to get ‘em going. Saves time, money, whole lot of hassle in day-to-day construction.

Geocells are flexible ‘cause of their design too. Their specs, things like tensile strength and bendability, let ‘em fit all kinds of scenarios. Take steep slopes, for example—geocells used there (up to 60 degrees or more) need higher tensile strength to fight gravity. Those used in wet areas have to handle waterlogging and chemical damage without falling apart. Manufacturers usually let you customize specs—project managers can pick the right cell size, wall thickness, material grade for what they need. That flexibility means geocells hold up well, no matter what unique challenges a project throws at ‘em.

Working with geocells is straightforward, easy on the budget—no fancy steps, no extra hassle. Come in flat, compact rolls. Moving and storing ‘em’s a breeze—no need for huge trucks or extra storage space. On-site, just unroll ‘em, expand ‘em into that honeycomb shape, stake ‘em down, fill ‘em up. No bunch of heavy equipment cluttering the site. Whole process moves pretty fast, cutting labor costs and shortening project timelines. Compared to traditional erosion control methods, geocells often save 30-50% on costs. Perform better long-term too—fewer repairs, less maintenance. This mix of easy installation, cost savings, solid performance has made geocells a top choice for engineers, contractors, environmental agencies.

How Geocells Enhance Ecological Restoration Efficiency

Ecological restoration’s a big part of modern infrastructure and environmental projects. Geocells have been a real game-changer here. Soil erosion usually goes hand in hand with habitat destruction. Lose that topsoil and vegetation, throw entire ecosystems out of whack. Geocells fix this by stopping erosion first, then creating the right conditions for plants to thrive. Help restore natural habitats, boost biodiversity—something traditional methods never quite pulled off.

Ecological restoration isn’t just about stopping erosion. It’s about letting nature bounce back on its own, honestly. Geocell specs line up perfectly with that goal. Cell size and thickness calibrated to let plant roots grow through without breaking the soil structure. Larger cells work for deep-rooted plants like shrubs, smaller ones for grasses and groundcovers. HDPE’s inert and non-toxic, so no harmful chemicals leach into the soil or water. Keeps plants, animals, even groundwater safe. Plus, geocells are porous. Rainwater soaks into the soil instead of running off, recharging groundwater supplies and lowering flood risk after heavy rains.

Geocells help with climate change adaptation too—something getting more important every year. Extreme weather like heavy downpours and storms is getting more common. Means higher erosion risk for slopes, riverbanks, farmland. Geocells absorb and slow down water runoff, cutting flooding and soil loss during these events. And the plants growing in geocells take in carbon dioxide, cutting greenhouse gas emissions—a definite win for the planet. So geocells aren’t just a quick fix for erosion. They’re a sustainable solution that tackles long-term environmental challenges.

Future Trends and Expanded Industry Applications

Awareness around soil erosion and environmental protection’s growing fast. So demand for geocells is only gonna keep growing. The construction industry’s leaning harder into sustainable practices—geocells fit right in ‘cause they’re cheap, eco-friendly, better than traditional materials like concrete. Governments around the world are tightening environmental rules too. That’s pushing more projects—from big infrastructure builds to small public works, land development—to use geocells instead of harmful, unsustainable options. It’s a trend that’s only getting stronger.

As demand for sustainable infrastructure grows, geocells are popping up in more and more projects. Geocell specs are evolving to keep up, too. Manufacturers are putting more into R&D to improve geocells: higher tensile strength, better UV resistance, more flexibility. Custom specs for extreme climates getting more common—deserts where temperatures soar, cold regions where frost heave is a problem. Same with geocells designed for heavy-load uses, like industrial sites or airport runways. More manufacturers using recycled materials to make geocells these days. Lowers their environmental footprint even more, making ‘em an even greener pick for eco-focused projects.

Geocell uses are expanding beyond just erosion control too. In agriculture, they’re used to make terraces on sloped farmland. Stop erosion, hold onto water—helps crops grow better, higher yields, less waste. In coastal areas, stabilize sand dunes, protect shorelines from wave and tide erosion. Even in cities, geocells are finding uses: green roofs, retaining walls, stormwater management systems. Helping make cities more sustainable and resilient, which is crucial as urban populations grow.

One more trend’s pairing geocells with other technologies—things like remote sensing and real-time monitoring systems. By putting sensors in geocell structures, project managers can track soil moisture, temperature, stability as the project progresses. That way, they can handle maintenance proactively instead of waiting for issues to crop up. This tech not only makes projects more successful. Gives valuable data to tweak geocell specs and designs for future projects—making ‘em even more effective.

Conclusion

From highway slopes to farmland, riverbanks to mine sites, geocells are making a real difference on actual job sites. Protect soil, preserve ecosystems, make infrastructure more stable. Their easy installation, cost savings, environmental benefits have made ‘em a favorite among engineers, contractors, environmental professionals. As the world keeps focusing on sustainability and climate resilience, demand for geocells will only grow. New uses and better specs will keep driving their evolution, making ‘em even more useful in the years to come.

In a time when soil erosion and environmental damage are big threats to our planet, geocells offer a practical, no-nonsense solution. Balance human needs with the natural world’s health—something hard to find in many construction materials. The fact they’re used so widely says it all: work well, and they’re valuable. They’ll definitely play a bigger part in building a more sustainable, resilient future. Whether it’s large-scale infrastructure projects or small-scale ecological restoration efforts, geocells show that simple, innovative design can make a huge difference in solving some of our most pressing environmental problems. They’re not just a tool for erosion control—they’re a tool for building a better world.