Building roads with low carbon, geogrid is the right time.

Low-Carbon Road Construction: Geogrids Are the Right Choice Right Now

In today’s infrastructure scene, “low-carbon” isn’t some fancy buzzword anymore—it’s a must. Governments, builders, green advocates everywhere are hunting for ways to slash carbon emissions at every step of the construction process. Road building? It’s one of the worst offenders when it comes to carbon footprints. Think digging up raw materials, running all those heavy machines—none of it’s kind to the planet. Finding eco-friendly fixes here isn’t optional; it’s a necessity. That’s where geogrids come in, quietly changing how we build roads while keeping carbon goals on track.

The Carbon Problem Plaguing Traditional Road Construction

Let’s be honest—traditional road building is far from green. First off, it guzzles huge amounts of natural aggregates: gravel, crushed stone, all that stuff. Quarrying these materials tears up big chunks of land, messes up local ecosystems, and pumps out tons of CO₂. Blame the bulldozers, excavators, transport trucks—they’re all in on it. Then there’s the maintenance hassle. Roads built the old way? They start sinking, cracking, getting ruts after just a few years. Fixing those issues? Needs even more materials, more machines, more trips to the site. Every single round-trip adds to the carbon count.

What’s worse, traditional road bases are usually overbuilt. Builders use way more material than needed just to make sure the road stays stable. This waste doesn’t just burn through cash—it burns energy too. Every ton of aggregate mined, processed, hauled? Uses fossil fuels. Adds to the greenhouse gases that warm the planet. As cities spread, rural areas need better roads—this cycle of high-carbon building and fixing gets harder to keep up with. Weak subgrades make it even worse. Left untreated, they deform fast under heavy traffic. You end up with “washboard” surfaces, potholes that force constant repairs. We need a solution that cuts materials, makes roads last longer, slashes emissions—all at once. And that solution? Closer than you think.

Another big issue with traditional road construction? How it harms soil quality. Heavy machines compact the soil under the road. Makes it hard for water to seep in, hard for plants to grow nearby. This leads to more runoff, which carries dirt and pollutants into rivers and streams. Over time, this hurts aquatic life. Makes the road less able to handle heavy rains—flood risks go up, more damage happens. It’s a vicious cycle old building methods can’t break. That’s why more and more construction pros are looking for alternatives that tackle both carbon emissions and ecological harm.

1.1 Geogrid Retaining Wall: A Game-Changer for Slope Stability

Building roads in hilly or mountainous areas? Slope stability is a huge worry. Traditional retaining walls—concrete or stone—they work, sure, but they come with a massive carbon price tag. Industry folks know it: concrete production alone accounts for around 8% of global CO₂ emissions. Stone walls? They need heavy materials hauled long distances. That boosts carbon footprints too. Then there’s the geogrid retaining wall—a lightweight, tough alternative that’s flipping the script. These walls use high-strength polymer geogrids to reinforce soil. Creates a stable structure without piles of concrete or stone. Cuts down material use, cuts the number of truck trips needed to haul supplies. Better yet, geogrid retaining walls are easier to install. Less time on-site means fewer emissions from construction machines. They’re flexible too—can handle small soil shifts without cracking or falling apart. For road builders aiming to go low-carbon? A geogrid retaining wall is a no-brainer for keeping slopes steady and emissions low.

How Geogrids Drive Low-Carbon Road Construction Forward

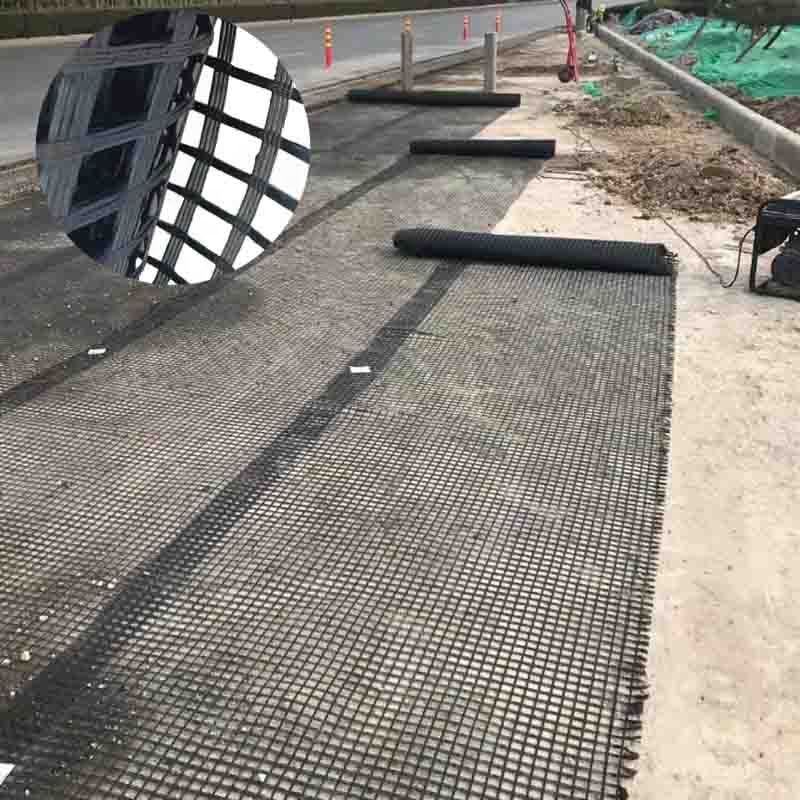

So, what are geogrids exactly? Put simply, they’re synthetic materials—usually polypropylene or polyester—made in a grid pattern. They look thin, but don’t let that fool you. These things are tough as nails. Geogrids are built to handle high tensile strength. Can take heavy loads without stretching or breaking. In road construction, you lay them in the road base layer. They act as a reinforcement system. Pros call this creating a “mechanically stabilized layer” (MSL). The grid locks aggregate particles together during compaction—kind of like a snowshoe spreading weight evenly over soft ground. This does two key things: spreads traffic weight more evenly across the road surface, stops the soil underneath from shifting or settling over time.

First big win with geogrids? Less material use. Because geogrids strengthen the road base, you don’t need as much aggregate as traditional methods. In some cases, you can cut aggregate use by up to 30%. That’s a huge drop in the material that needs quarrying and hauling. Less quarrying means less land disruption. Less hauling means fewer truck emissions. Win for the planet, win for the construction budget. Let’s keep it real—every project has a bottom line. Saving money on materials while going green? Massive selling point for geogrids.

Another key plus? Geogrids make roads last longer. Roads reinforced with geogrids? Way less likely to get potholes, cracks, ruts. That means fewer maintenance runs, fewer repairs, fewer emissions from maintenance vehicles. Think about it: a road that lasts 20 years instead of 10? Cuts the number of tear-downs and rebuilds in half. Tons of carbon saved over time. Geogrids help with reflective cracking too—one of the biggest issues for flexible pavements. Add a grid interlayer? Stops cracks from spreading up through the surface. Road stays smooth longer. They even make roads better at handling heavy traffic. Important as more trucks hit the roads to move goods. Busy highway, rural access road—geogrids make it tougher, longer-lasting.

Geogrids help with road water management too. Traditional road bases? Get waterlogged after heavy rain. Weakens the structure, causes damage. Geogrids have an open grid design. Lets water drain through the road base more easily. Reduces waterlogging, keeps the road stable even in wet weather. Better drainage means less runoff—protects nearby waterways from pollution. Just another way geogrids make road construction more sustainable.

2.1 Geogrid Retaining Wall: Blending Function and Eco-Friendliness in Roadside Projects

Roadside construction often means building retaining walls. Stop erosion, protect nearby properties—all that. But as we said before, traditional walls are andrains. Helps recharge groundwater, lowers flood risks. What’s more, you can cover these walls with plants. Improves their look, adds another layer of erosion control and carbon capture. For roadside projects that need to balance function and eco-friendliness? A geogrid retaining wall is perfect. Tough, cheap, kind to the planet—everything you want in a low-carbon construction solution.ything but green. The geogrid retaining wall? Better option, hands down. Unlike heavy, rigid concrete walls, geogrid retaining walls are built by filling grid cells with local soil or recycled materials. Use what’s already on-site? Cuts hauling costs, cuts emissions. These walls are permeable too—let water seep through instead of running into

The Future of Low-Carbon Roads: Geogrids Leading the Way

As the world pushes harder for net-zero emissions, demand for sustainable construction materials will only grow. Geogrids? They’re already gaining ground in road building, but their full potential’s far from tapped. Next few years? We’ll see even more geogrid tech innovations. Think stronger, more durable polymers. Grids that biodegrade over time after they’ve done their job. These upgrades will make geogrids even more appealing for low-carbon road construction.

Governments are starting to see the value of geogrids too—for meeting carbon reduction targets. Many countries now offer incentives for projects using sustainable materials and methods. Tax breaks, grants, faster permits—all for projects that use geogrids and other green tech. As these incentives become more common, more builders will switch to geogrids. This trend? Only speeds up as the world gets serious about fighting climate change.

Another exciting development? Using geogrids with other sustainable materials. For example, some projects pair geogrids with recycled asphalt pavement (RAP) to make even greener road bases. RAP cuts down on the need for new asphalt—made from oil, a finite resource. Combine RAP with geogrids? Creates a road base just as strong as traditional ones, but with a fraction of the carbon footprint. Even for rigid pavements, geogrids prove useful. Reduce the need for thick aggregate bases, make the whole structure lighter, more eco-friendly. This kind of innovation? It’ll drive the future of low-carbon road construction.

3.1 Geogrid Retaining Wall: Paving the Path for Sustainable Infrastructure Expansion

As cities spread, roads get built into untouched areas—the need for sustainable slope stabilization grows even more. The geogrid retaining wall? Perfectly suited to meet this demand. Its lightweight design makes it ideal for remote areas. Hauling heavy concrete or stone there? Hard, expensive. Geogrid walls skip that hassle. Their eco-friendly build means you can use them in environmentally sensitive areas without harming local ecosystems. Better yet, geogrid retaining walls go up fast. Speeds up project timelines, cuts down on construction emissions. Rural bypass, mountain highway—these walls fit right in with low-carbon goals. As we build more roads to connect communities and protect the planet, the geogrid retaining wall will be a key tool in our low-carbon infrastructure toolbox. It’s a solution that works for people and the environment—and that’s the kind of innovation we need more of.

Conclusion

Low-carbon road construction is the future—no getting around it. Traditional building methods? Use too many resources, pump out too much carbon to be sustainable long-term. Geogrids offer a practical, cost-effective, eco-friendly alternative. Fixes all the big issues with traditional road building: cuts material use, extends road life, improves water management, slashes emissions. Geogrids check every box for a sustainable construction solution.

And we can’t forget the role of the geogrid retaining wall in this shift. Stabilizing slopes in mountains, protecting roadside properties from erosion—these walls prove sustainable construction doesn’t mean giving up on function. They’re a perfect example of how innovative materials help us build a better, greener world.

As more construction pros learn about geogrids’ benefits—from the “snowshoe effect” on weak subgrades to the cost savings of reduced aggregates—they’ll become a staple in road projects worldwide. The days of high-carbon, wasteful road building are coming to an end. With geogrids leading the way, we’re one step closer to building roads that are strong, durable, kind to the planet. Low-carbon road construction isn’t just a trend—it’s a responsibility. And geogrids? They’re the right choice, right now, to help us meet that responsibility head-on.