Composite Geomembrane: An Excellent Engineering Anti - seepage Guardian

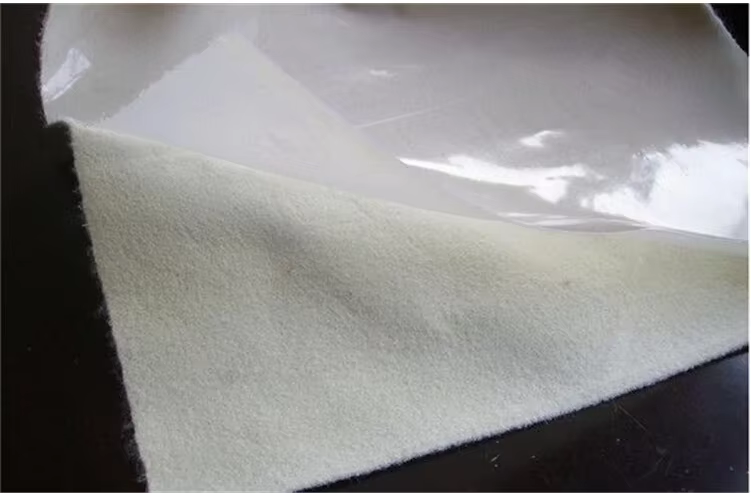

Composite geomembrane is a high - performance geosynthetic material, which is composed of a geomembrane (the core anti - seepage layer) and at least one layer of geotextile through processes such as thermal compounding, adhesive compounding or needling. Composite geomembrane cleverly combines the excellent anti - seepage/water - proof performance of the geomembrane with the protection, reinforcement, drainage (or reverse filtration) functions of the geotextile.

Core Structure:

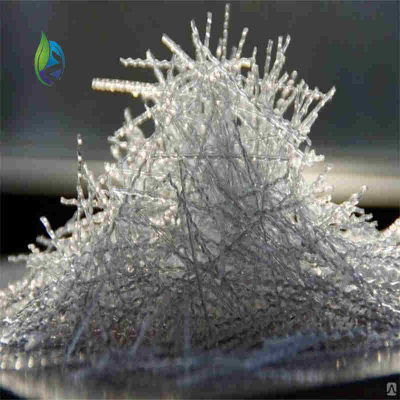

Impermeable Layer (Geomembrane): It usually uses polymer materials such as high - density polyethylene (HDPE), low - density polyethylene (LDPE), linear low - density polyethylene (LLDPE), polyvinyl chloride (PVC), ethylene - vinyl acetate copolymer (EVA). It provides excellent liquid and gas barrier performance.

Protective and Reinforcing Layer (Geotextile): It usually uses polyester (PET) or polypropylene (PP) needle - punched non - woven fabric or woven fabric. Its main functions are as follows:

Protection: Prevent the geomembrane from being punctured or scratched by sharp gravel, backfill materials or upper loads during construction and service.

Reinforcement: Improve the overall tensile strength, tear resistance and puncture resistance of the material, and enhance the interface friction performance with the soil.

Drainage/Exhaust: The fabric layer can form drainage channels to dredge the accumulated water or gas that may be generated under the membrane (especially in the structure of one fabric and one membrane).

Stress Dispersion: Disperse the local stress caused by the upper load or uneven settlement of the foundation to protect the geomembrane.

Common Types:

One fabric and one membrane: One layer of geotextile is compounded with one layer of geomembrane. It has the functions of protection, reinforcement and basic drainage.

Two fabrics and one membrane: Two layers of geotextile are compounded with one layer of geomembrane. It provides better two - way protection, reinforcement and drainage capacity, and is a commonly used type.

Multi - fabric and multi - membrane: Customized according to special engineering needs, it provides super protection or composite functions.

Core Characteristics and Advantages of Composite Geomembrane:

Excellent Anti - seepage: Composite Geomembrane has an extremely low hydraulic conductivity (usually <10⁻¹¹ cm/s), and is the core material for building a reliable anti - seepage barrier.

Ultra - high Strength and Durability: The reinforcement of geotextile greatly improves the tensile, tear and puncture resistance of the material, and extends its service life (the design life can reach 50 - 100 years).

Strong Integrity: The composite structure avoids the tediousness and dislocation risk of laying multiple layers of materials (membrane + fabric) on site, with high construction efficiency and more controllable quality.

Adaptability to Deformation: Good flexibility enables it to adapt to moderate deformation of the foundation.

Chemical Corrosion Resistance: Polymer materials can resist the erosion of various acids, alkalis, salts and organic substances, and are especially suitable for harsh environments such as landfills.

Convenient Construction: Composite Geomembrane has a wide width (usually 4 - 8 meters), relatively light weight per unit area, and high efficiency in laying and welding.

Cost - effectiveness: Although the unit price may be higher than that of a single - layer membrane, it has significant long - term economic benefits considering its advantages such as protection, simplified construction, reduced maintenance and extended engineering life.

Main Application Scenarios

With its comprehensive advantages of "anti - seepage + protection", composite geomembrane is widely used in various civil engineering, water conservancy and environmental protection projects that have strict requirements for anti - seepage and isolation:

1. Environmental Protection Engineering:

Sanitary Landfills: Foundation anti - seepage liners, leachate collection and drainage layer liners, and the core anti - seepage layer of the closure covering system. It is a key barrier to prevent toxic leachate from polluting soil and groundwater.

Hazardous Waste Disposal Sites: Prevent the leakage of harmful substances.

Sewage Treatment Plants: Anti - seepage liners for regulating tanks, anaerobic ponds, oxidation ponds, aeration tanks, sludge thickening tanks, etc.

Tailings Ponds/Red Mud Storage Sites: Anti - seepage for the bottom of the pond, in front of the dam and the slope of the reservoir area to prevent heavy metals or toxic substances from leaking with rainwater and polluting the environment.

2. Water Conservancy and Hydropower Engineering:

Artificial Lakes, Landscape Ponds, Rivers: Lining anti - seepage to reduce water loss.

Reservoir/Canal Lining: Improve water delivery efficiency, reduce leakage loss, and prevent salinization or collapsibility of the canal bed.

Dams/Embankments: Anti - seepage for the upstream slope, vertical anti - seepage walls, and anti - seepage blankets in the reservoir area.

Seawater/Saline - alkali Land Aquaculture Ponds: Anti - seepage and water retention to prevent salt from infiltrating and polluting groundwater or fresh water from infiltrating and affecting salinity.

3. Municipal and Construction Engineering:

Underground Engineering (Basements, Tunnels): Waterproof and moisture - proof layers.

Roof Gardens/Planting Roofs: Waterproof and root - resistant layers.

Artificial Wetlands: Bottom anti - seepage liners.

4. Transportation Engineering:

Highway/Railway Subgrades: Isolation layers (to prevent intermixing of weak foundations and fillers), anti - capillary water rise layers.

Tunnels/culverts: Waterproof layers.

5. Mining and Energy:

Heap Leaching Sites: Prevent the leakage and pollution of leachate.

Evaporation Ponds (such as coal mines, power plants): Store high - salinity wastewater to prevent leakage.

Construction Methods (Key Steps and Points)

The construction quality of composite geomembrane directly determines its anti - seepage effect and engineering life, and must strictly follow the specifications. The main processes are as follows:

1. Subgrade Treatment:

Thoroughly remove sharp debris such as tree roots, stones, gravel, steel bars on the surface of the subgrade (soil base, concrete base or gravel cushion, etc.).

Level and compact to meet the design requirements of compactness and flatness. The slope and slope direction should conform to the design requirements (conducive to drainage).

Repair and level cracks, holes, etc. in the rock base or concrete base.

When laying a sand cushion or geotextile (if additional protection is needed), ensure it is flat and dense.

2. Material Laying:

Planning and Cutting of Composite Geomembrane: Pre - plan the laying scheme according to the size and shape of the site to minimize on - site cutting and the number of welds. Sufficient lap width should be reserved for cutting.

Laying Direction: Usually lay along the slope direction (from the top to the bottom of the slope) or along the long side of the site. The fabric surface (rough surface) is generally downward to contact the subgrade (protective film), and the smooth membrane surface is upward. The specific direction should be determined according to the design (such as drainage requirements).

Laying Method: Manually roll or mechanically pull to unfold. Keep the membrane surface flat and naturally loose (reserve about 1.5% expansion margin to adapt to temperature changes and subgrade deformation), avoid being tight, wrinkled or suspended. Manually tighten and adjust.

Lap Width: The effective welding lap width between membranes should not be less than 10 cm. If the fabrics need to be sewn, the lap width should also meet the design requirements (usually more than 15 - 20 cm).

3. Welding/Sewing:

Membrane - to - Membrane Connection (Core): Hot melt welding must be used.

Double - track Hot Melt Welding: A commonly used method, using a double - track hot wedge welding machine to produce two parallel molten welds, forming a closed cavity in the middle. After welding, the cavity should be subject to air pressure testing.

Extrusion Welding: Use a welding gun to extrude molten solder to form a strip - shaped weld at the lap joint. It is suitable for complex parts (such as corners, repairs, T - type connections), thick materials or on - site repairs.

Welding Parameters: Strictly control the welding temperature, speed and pressure (adjust according to material type, thickness and ambient temperature) to ensure that the weld is fully melted and uniformly continuous. Before formal welding, test welding and destructive tests of welds (shear and peel) must be carried out to determine the specified parameters.

Fabric - to - Fabric Connection: Usually use the sewing method (hand - held sewing machine or industrial sewing machine) with polyester thread of matching strength. Lap joint or bonding can also be used (in specific occasions).

4. Weld Inspection:

Visual Inspection: Check whether the weld appearance is continuous, flat, uniform, free of scalds, no impurity inclusion, no missing welding or virtual welding.

Non - destructive Testing:

Air Pressure Testing (Double - track Welds): Inflate the closed cavity between the double - track welds (about 200 - 250 kPa), keep the pressure for 2 - 5 minutes, and observe whether the pressure drop exceeds the allowable value (usually ≤20%).

Vacuum Cover Testing (Complex Parts, Repair Points): Apply soapy water on the weld, cover it with a vacuum cover and vacuum, and observe whether there are bubbles.

Spark Testing (Only for Conductive Geomembranes such as HDPE containing carbon black): Lay metal wires on the membrane, connect high - voltage electricity, scan the weld, and sparks will be generated when leakage points are encountered.

Destructive Testing: Cut weld samples on site for laboratory shear and peel strength tests according to specifications. The results should not be less than 80% of the base material strength (shear) or the base material itself (peel).

5. Anchoring:

At the structural boundaries (such as dam top, toothed wall, anchoring trench), the composite geomembrane must be firmly anchored. Common methods:

Anchoring Trench: Excavate a trench (depth and width usually ≥1m) at the edge of the structure, bury the membrane in the trench, and backfill and compact.

Concrete Toothed Wall/Coping: Bury the membrane in the concrete structure.

Shooting Nails/Expansion Bolts + Pressing Strip (Rigid Structure): Used for hard boundaries such as concrete.

6. Backfill Protection:

After the welding inspection is qualified, the protective layer (such as sand, gravel, concrete slab, etc.) should be covered in time.

The protective layer material must not contain sharp debris, and the laying thickness should meet the design requirements.

Be careful during backfilling to avoid heavy machinery directly walking or unloading on the exposed membrane. It is advisable to backfill from the bottom to the top of the slope, and equipment such as bulldozers should travel parallel to the laying direction.

Backfill and compact in layers to avoid local impact loads damaging the geomembrane.

Important Notes:

Weather: Avoid construction in rain, snow, strong winds (> level 4), low temperatures (<5℃) or high - temperature exposure. Preheating or heat preservation measures are required at low temperatures; prevent scalds and excessive relaxation at high temperatures.

On - site Protection: After laying, the exposed membrane that is not covered in time should be protected from man - made treading, vehicle rolling, tool falling, fire scalding, etc.

Detail Handling: For special parts such as pipeline membrane penetration, internal and external corners, expansion joints, etc., special construction schemes must be formulated and carefully handled (often using prefabricated parts, reinforcing layers, sealants, etc.) to ensure reliable sealing.

Quality Records: Record material inspection reports, welding parameters, test results, construction logs, etc. in detail.

Summary:

Composite geomembrane is an indispensable key anti - seepage material in modern engineering construction. Composite Geomembrane's unique "membrane + fabric" composite structure endows it with unparalleled anti - seepage reliability, physical durability and construction convenience. From landfills that protect the environment to water conservancy projects that ensure water sources, and transportation facilities that stabilize foundations, composite geomembrane plays an irreplaceable role silently. Successful application not only depends on the excellent performance of the material, but also on strict and standardized construction techniques and a sound quality control system. Choosing the appropriate specification and model, and laying, welding and protecting in strict accordance with scientific methods can ensure that this "underground Great Wall" is durable and provide a solid guarantee for engineering safety and environmental protection.