HDPE geomembrane liner local damage repair methods

HDPE Geomembrane Liner Local Damage Repair Methods

Introduction

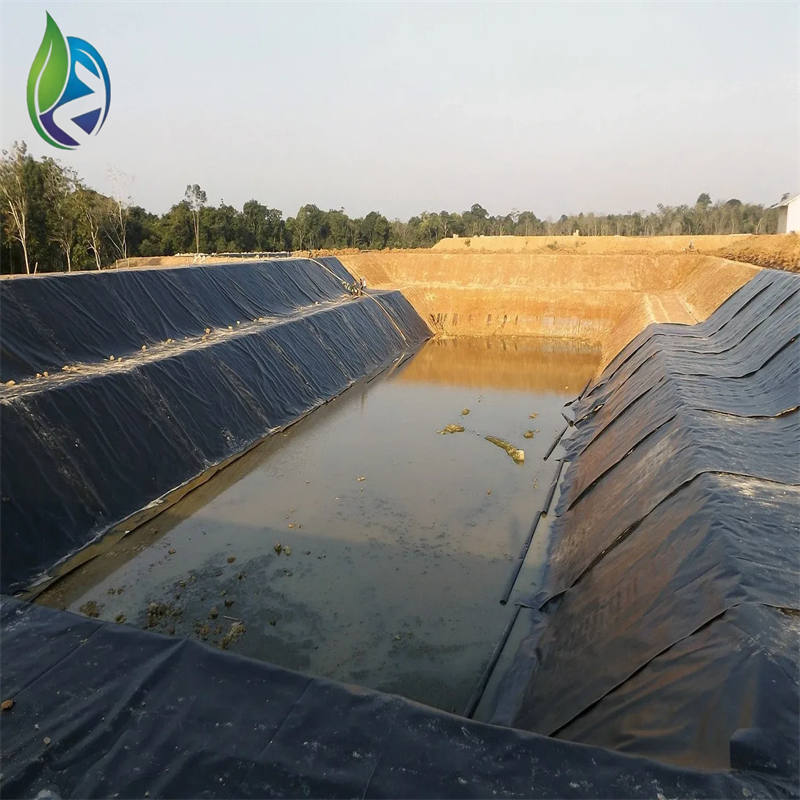

HDPE (High-Density Polyethylene) geomembrane liners are a cornerstone in a wide range of applications, including landfills, wastewater treatment plants, pond linings, and mining operations. Known for their durability, chemical resistance, and cost-effectiveness, these liners provide critical protection to the environment by preventing leakage and soil contamination. However, despite their robustness, local damage can occur due to factors such as physical punctures, abrasion, or environmental stress.

When damage occurs, timely and effective repairs are essential to restore the integrity of the liner and prevent further damage. In this article, we will explore the methods for repairing local damage to HDPE geomembrane liners, the tools and materials required, and best practices to ensure a long-lasting and reliable repair.

Understanding HDPE Geomembrane Liners

What is an HDPE Geomembrane Liner?

An HDPE geomembrane liner is a synthetic polymer sheet used in containment systems to prevent the migration of liquids or gases. These liners are commonly used in various industries such as landfills, chemical containment, water reservoirs, and agriculture. HDPE geomembranes offer excellent resistance to chemicals, UV rays, and physical damage, making them a preferred choice in demanding environments.

Despite their durability, they are not immune to local damage, which can be caused by factors like sharp objects, ground movement, or extreme weather conditions.

The Importance of Timely Repairs

Timely repairs of local damage are essential for maintaining the integrity and functionality of HDPE geomembrane liners. Failure to repair punctures, tears, or other damage can result in leakage, contamination, and environmental harm. Therefore, quick identification and proper repair methods are crucial for ensuring long-term performance and avoiding costly replacements.

Methods for Repairing Local Damage to HDPE Geomembrane Liners

1. Surface Preparation

Before applying any repair material, the surface of the damaged area must be properly prepared to ensure a strong bond between the geomembrane and the repair material. This includes:

Cleaning the damaged area: Ensure the surface is free from dirt, debris, oil, or water. A clean surface ensures that the adhesive or repair material will bond effectively.

Drying the surface: If the area is wet, allow it to dry completely. Moisture can weaken the bond and cause repair failure.

Trimming: Cut the damaged edges into a neat, clean shape to allow for better adhesion of the patch.

2. Using HDPE Geomembrane Patch

One of the most effective methods of repairing local damage is to use an HDPE patch. This involves:

Selecting a compatible HDPE patch material: The patch material should be of the same or similar grade and thickness as the original geomembrane liner.

Cutting the patch: The patch should be at least 4–6 inches larger than the damaged area on all sides to ensure full coverage.

Applying adhesive or heat welding: Depending on the repair kit, you can either apply a specialized adhesive or use heat welding to bond the patch to the geomembrane.

3. Heat Sealing and Fusion Welding

For more permanent and seamless repairs, heat sealing or fusion welding is often the best method. This technique is particularly effective for larger damage areas and is highly durable.

Heat Sealing: A hot air gun or infrared heater is used to melt the edges of the geomembrane and the patch material. Once the materials become soft, they are pressed together to form a strong bond.

Fusion Welding: This method uses electrofusion or extrusion welding to fuse the geomembrane to the patch, ensuring a high-quality, watertight seal. Fusion welding is typically used for larger applications and critical repairs.

4. Using Patches with Self-Adhesive Backing

In situations where a quick and simple repair is required, self-adhesive HDPE patches can be used. These patches have an adhesive layer on the back, making the application process easier and faster. However, self-adhesive patches are best for small punctures and minor damage.

Peel and Stick Application: Simply peel off the protective backing, place the patch over the damaged area, and press down to ensure adhesion. This method is suitable for temporary repairs or when quick fixes are needed.

5. Cold-Applied Adhesives and Tapes

For localized damage where heat is not an option, cold-applied adhesives and repair tapes can be an excellent choice. These adhesives are formulated to bond securely with the geomembrane and provide watertight repairs without the need for welding or heat.

Cold-Applied Adhesive: This is a solvent-based adhesive used to bond patches to the geomembrane. It is particularly effective in low-temperature environments.

Geomembrane Repair Tape: This tape is designed for quick, easy repairs and provides a temporary fix. It is ideal for smaller punctures and tears.

Best Practices for Repairing HDPE Geomembrane Liners

1. Conduct Regular Inspections

Regular inspections of HDPE geomembranes are crucial to identifying early signs of damage. This allows for quick intervention before the damage becomes more severe.

Visual Inspection: Look for visible signs of damage such as holes, tears, or punctures.

Leak Detection: Perform leak detection tests like vacuum box tests or tracer gas tests to identify small leaks.

2. Use the Right Repair Materials

Always use repair materials that are compatible with the original geomembrane. Using materials of similar composition ensures a strong bond and prevents future damage. Many manufacturers provide repair kits that include HDPE patches, adhesives, and heat sealing tools.

3. Ensure Proper Curing Time

If using adhesives or cold-applied products, make sure the materials are given sufficient time to cure before applying pressure or exposing the repaired area to harsh conditions. This ensures a strong and durable bond.

4. Train Your Team

Proper training for workers involved in geomembrane repairs is essential. Training in patching techniques, surface preparation, and the use of welding equipment will ensure that repairs are conducted safely and efficiently.

Frequently Asked Questions (FAQ)

1. Can HDPE geomembrane repairs be permanent?

Yes, with the right repair techniques, such as fusion welding or heat sealing, HDPE geomembrane repairs can be permanent and provide long-lasting results.

2. What tools are needed for repairing HDPE geomembrane liners?

Common tools include hot air guns, welding machines, adhesive applicators, and patching materials. The specific tools required depend on the repair method being used.

3. How long does it take for a repair to cure?

The curing time depends on the type of repair material used. For adhesives, curing time can range from a few hours to 24 hours, while welded repairs may be immediately functional once the welding process is complete.

4. Are there any environmental considerations when repairing HDPE geomembranes?

Yes, it’s important to conduct repairs in dry conditions and to avoid excessive exposure to sunlight or chemicals before the repair material fully bonds. Temperature and humidity can affect curing times and the overall effectiveness of the repair.

Conclusion and Call to Action

Repairing local damage to HDPE geomembrane liners is essential for maintaining the integrity of your containment system and preventing costly environmental damage. By using the appropriate repair methods—such as patching, heat sealing, fusion welding, or adhesive solutions—you can ensure that your geomembrane continues to perform efficiently and safely.

If you are looking for high-quality HDPE geomembrane liners and repair solutions, we offer a range of materials and tools to meet your project’s specific needs. Whether you need patch kits, adhesives, or welding equipment, our solutions are designed to ensure long-lasting, effective repairs.

Contact us today to learn more about our geomembrane repair products and how we can help you maintain the durability and performance of your containment systems.