Geogrid helps, making the high-speed railway subgrade as stable as a mountain

Product Definition

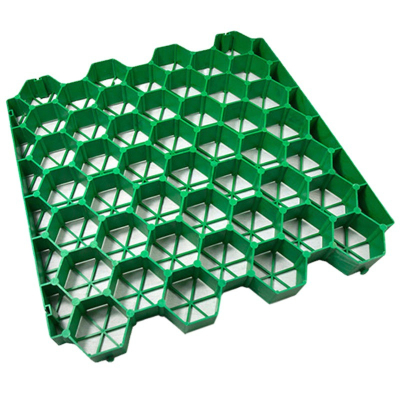

Geogrid is a polymer-based geosynthetic reinforcement material designed to improve the mechanical stability of soil structures. In high-speed railway subgrade engineering, geogrids enhance load distribution, limit deformation, and increase bearing capacity, ensuring long-term track stability under dynamic and repeated train loads.

Technical Parameters and Specifications

Geogrids used in high-speed railway subgrades must meet strict mechanical and durability requirements to perform under high cyclic loads and long design life conditions.

Material types: PP, PET, HDPE

Tensile strength (MD/CD): 30–200 kN/m

Elongation at maximum load: ≤10% (PET), ≤15% (PP)

Junction efficiency: ≥90%

Aperture size: 20 × 20 mm to 60 × 60 mm

Creep reduction factor: ≤1.5 (120 years design life)

Durability: ≥100 years in buried conditions

UV resistance (retained strength): ≥70% after 500 hours

Operating temperature range: -40°C to +60°C

Structure and Material Composition

High-performance geogrids for railway subgrades are engineered with optimized grid geometry and polymer formulation.

Primary Load-Bearing Ribs: Oriented polymer strips providing tensile strength

Transverse Ribs: Maintain structural integrity and load transfer

Junction Nodes: High-strength welded or extruded intersections

Polymer Matrix: UV-stabilized and oxidation-resistant resin

Surface Texture: Improves interlock with granular fill

Manufacturing Process and Engineering Controls

Engineering Manufacturing Steps

Polymer resin selection and formulation

Sheet extrusion or strip extrusion

Precision punching or stretching

Uniaxial or biaxial molecular orientation

Thermal setting and stress stabilization

Roll cutting and quality inspection

Key Equipment and Process Control Points

Production lines include high-precision extruders, stretching frames, and automated tensile testing systems. Critical controls focus on orientation ratio, junction integrity, and tensile strength uniformity to ensure predictable reinforcement performance in railway applications.

Industry Comparison: Subgrade Reinforcement Solutions

| Reinforcement Method | Load Distribution | Construction Efficiency | Long-Term Stability | Typical Use |

|---|---|---|---|---|

| Geogrid Reinforcement | Excellent | High | Very High | High-speed rail subgrades |

| Soil Replacement | Moderate | Low | Moderate | Weak foundation treatment |

| Cement Stabilization | High | Medium | High | Rigid subgrade layers |

| Pile Reinforcement | Very High | Low | Very High | Deep soft soil areas |

Application Scenarios and Stakeholders

Geogrids are widely applied in:

High-speed railway subgrade reinforcement

Ballast and ballastless track structures

Embankments on soft soil foundations

Transition zones near bridges and tunnels

Railway slope stabilization

Key stakeholders include EPC contractors, railway engineering bureaus, infrastructure developers, geosynthetics distributors, and technical consultants.

Core Pain Points and Engineering Solutions

Pain Point 1: Differential Settlement Under Dynamic Loads

Solution: Use high-modulus geogrids to evenly distribute train loads and reduce localized deformation.

Pain Point 2: Insufficient Bearing Capacity of Subgrade Soil

Solution: Geogrid-soil interlock increases composite stiffness and bearing capacity.

Pain Point 3: Long-Term Creep and Deformation

Solution: Select PET geogrids with low creep characteristics for long design life.

Pain Point 4: Construction Efficiency and Cost Control

Solution: Geogrids reduce fill thickness and earthwork volume, improving efficiency.

Risk Warnings and Mitigation Measures

Risk: Incorrect geogrid orientation

Mitigation: Ensure alignment with principal stress directionRisk: Damage during backfilling

Mitigation: Use controlled compaction and proper cover thicknessRisk: Insufficient overlap between rolls

Mitigation: Follow design overlap specifications (typically ≥300 mm)Risk: UV exposure before burial

Mitigation: Limit exposure time or provide temporary covering

Procurement and Selection Guide

Define railway design speed and axle load requirements

Evaluate subgrade soil properties and bearing capacity

Select geogrid type (uniaxial or biaxial)

Determine required tensile strength and stiffness

Verify compliance with railway and infrastructure standards

Review laboratory test reports and creep data

Request project-specific samples and technical support

Engineering Case Study

In a high-speed railway embankment project crossing soft clay soil, a biaxial PET geogrid with 80 kN/m tensile strength was installed in multiple layers within the subgrade. Field monitoring showed a settlement reduction of over 35% compared to untreated sections, while track geometry remained within tolerance after several years of operation.

Frequently Asked Questions (FAQ)

Q1: Why are geogrids critical for high-speed railways?

They control deformation under repeated high-speed dynamic loads.

Q2: What geogrid type is most common for subgrades?

Biaxial PET geogrids are widely used.

Q3: How does geogrid improve stability?

Through soil interlock and tensile reinforcement.

Q4: Can geogrids replace soil stabilization?

They complement or reduce the need for chemical stabilization.

Q5: What is the typical installation depth?

Usually within the upper subgrade layers.

Q6: Are geogrids suitable for soft soil areas?

Yes, especially when combined with drainage solutions.

Q7: How is geogrid quality verified?

Through tensile, creep, and junction strength testing.

Q8: Do geogrids affect construction speed?

They typically accelerate construction by reducing rework.

Q9: Is long-term maintenance required?

No, geogrids are maintenance-free once buried.

Q10: Can geogrids be used in ballastless tracks?

Yes, particularly in transition and reinforcement zones.

Call to Action

For high-speed railway subgrade reinforcement solutions, detailed geogrid specifications, engineering calculations, or project samples, procurement and engineering teams are encouraged to request technical documentation and professional support from qualified geogrid manufacturers.

E-E-A-T: Author Expertise and Industry Authority

This article is authored by a geotechnical engineering specialist with extensive experience in railway infrastructure and geosynthetic reinforcement systems, providing reliable, engineering-based insights for B2B decision-makers in large-scale transportation projects.