Bentonite Clay Liner

Manufacturing Process

The industrial production process of Bentonite Clay Liner follows controlled engineering steps:

Raw sodium bentonite drying and particle size classification

Automated dosing and uniform distribution on carrier geotextile

Needle punching or stitch-bonding to mechanically encapsulate bentonite

Calendering under controlled pressure to stabilize thickness

Optional polyethylene film lamination

Inline quality inspection for mass per unit area and uniformity

Roll cutting, wrapping, labeling, and traceability marking

Product Definition

Bentonite Clay Liner is a low-permeability geosynthetic barrier system that utilizes sodium bentonite’s swelling and self-sealing properties to form an engineered hydraulic barrier, widely applied in containment and environmental protection projects requiring long-term groundwater and leachate control.

Technical Parameters and Specifications

Standard engineering specifications for Bentonite Clay Liner in infrastructure and environmental projects:

Core material: Sodium bentonite clay

Mass per unit area: 4.0 – 6.0 kg/m²

Hydraulic conductivity: ≤ 5 × 10⁻¹¹ m/s

Free swell index: 20 – 30 mL/2g

Moisture content: 10% – 15%

Peel strength (textile layers): ≥ 50 N/100 mm

Internal shear strength: 20 – 35 kPa

Service temperature range: -30°C to +60°C

Chemical resistance: Suitable for mild acids, alkalis, and salts

Design service life: 20 – 40 years in buried conditions

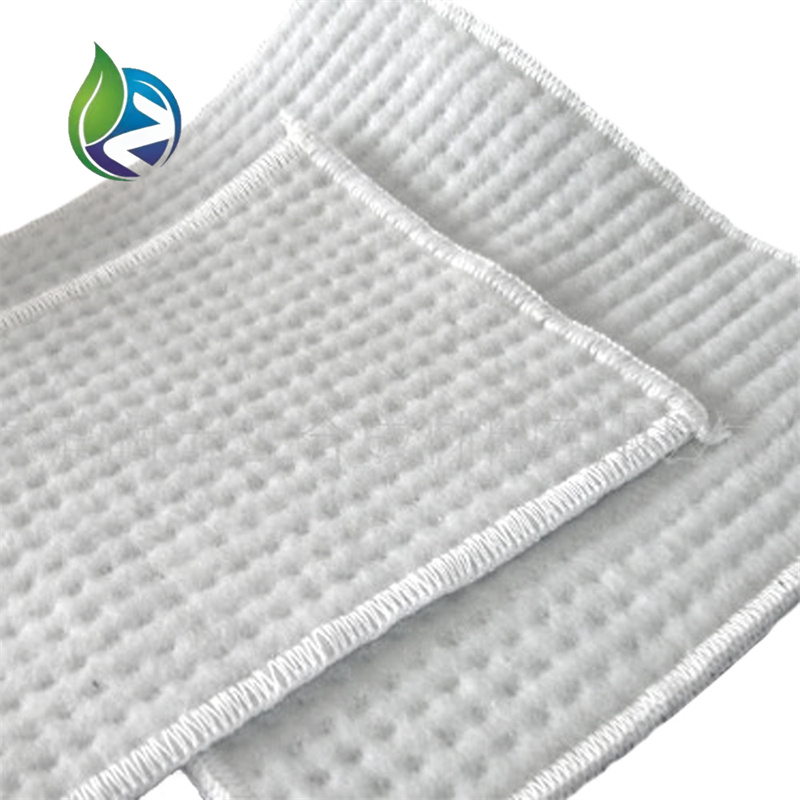

Structure and Material Composition

The layered structure of Bentonite Clay Liner typically consists of:

Upper layer: Nonwoven polypropylene geotextile

Core layer: Uniformly distributed sodium bentonite granules or powder

Lower layer: Woven or nonwoven geotextile backing fabric

Reinforcement method: Needle-punched or stitch-bonded fiber structure

Optional laminate: HDPE film coating for composite containment systems

Manufacturing Process

The industrial production process of Bentonite Clay Liner follows controlled engineering steps:

Raw sodium bentonite drying and particle size classification

Automated dosing and uniform distribution on carrier geotextile

Needle punching or stitch-bonding to mechanically encapsulate bentonite

Calendering under controlled pressure to stabilize thickness

Optional polyethylene film lamination

Inline quality inspection for mass per unit area and uniformity

Roll cutting, wrapping, labeling, and traceability marking

Industry Comparison

| Liner Type | Permeability | Self-Sealing Ability | Installation Complexity | Typical Service Life |

|---|---|---|---|---|

| Bentonite Clay Liner | Very Low | Excellent | Low | 20–40 Years |

| HDPE Geomembrane | Extremely Low | None | High | 25–30 Years |

| Compacted Clay Liner | Low | Limited | High | 15–25 Years |

| PVC Liner | Low | None | Medium | 10–15 Years |

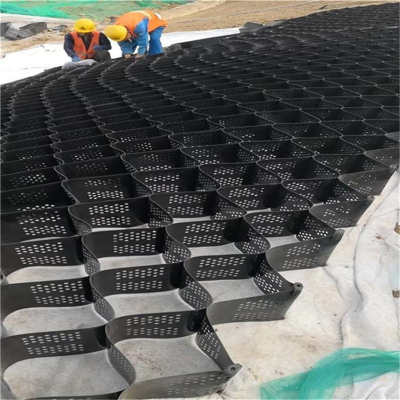

Application Scenarios

Bentonite Clay Liner is specified by:

Geosynthetics distributors servicing environmental construction markets

EPC contractors executing landfill and mining containment systems

Civil engineering firms responsible for groundwater protection design

Industrial owners developing wastewater and hazardous waste facilities

Engineering uses include landfill base liners, capping systems, decorative and industrial ponds, canals, secondary containment zones, and foundation waterproofing works.

Core Pain Points and Solutions

Leakage through micro-defects — resolved by bentonite’s self-sealing swelling mechanism

Inconsistent barrier thickness — addressed by factory-controlled mass per unit area

Time-consuming clay compaction — eliminated by prefabricated liner roll installation

Subgrade movement — mitigated through flexible geotextile-reinforced structure

Risk Warnings and Mitigation Recommendations

Premature hydration before backfilling may reduce performance — keep material dry until placement

High salinity liquids may limit bentonite swelling — verify chemical compatibility

Poor overlap detailing may cause leakage paths — follow specified overlap and sealing standards

Sharp subgrade particles may puncture textile layers — install cushioning geotextiles where required

Procurement and Selection Guide

Define project hydraulic conductivity and containment requirements

Select appropriate bentonite mass per unit area based on risk profile

Verify factory test reports and material batch traceability

Confirm compatibility with expected chemical exposure

Review installation method statements from supplier

Request laboratory samples for swell and permeability testing

Plan inspection and documentation process with EPC contractor

Engineering Case Example

In a regional hazardous waste landfill project, a 5.0 kg/m² Bentonite Clay Liner was installed across approximately 38,000 m² as a secondary containment layer. The system was placed over compacted subgrade and protected by a drainage composite, achieving long-term permeability compliance under enforced regulatory audits.

FAQ

Q1: What is the typical overlap width during installation?

A: 150–300 mm.Q2: Can it be installed in cold climates?

A: Yes, when handled and stored properly.Q3: Is hydration required before backfilling?

A: No, hydration occurs naturally after placement.Q4: Can it replace compacted clay liners?

A: Yes, in many engineered designs.Q5: What is the typical roll width?

A: 4–5 meters.Q6: How is quality verified on site?

A: By checking mass per unit area and visual inspection.Q7: Does it require welding like HDPE liners?

A: No, overlaps rely on bentonite swelling.Q8: Can it be combined with geomembranes?

A: Yes, as part of composite liner systems.Q9: What subgrade preparation is required?

A: Smooth, compacted, and free of sharp objects.Q10: Is it resistant to roots and biological intrusion?

A: Yes, under standard buried conditions.

CTA – Commercial Technical Request

For project procurement, submit formal requests for quotation, detailed technical documentation, and engineering-grade samples of Bentonite Clay Liner through qualified technical sales representatives.

E-E-A-T Author Credentials

This content is prepared by experienced geotechnical and environmental engineering specialists with more than 15 years of professional practice in geosynthetics design, containment engineering, and EPC technical advisory services for large-scale infrastructure and environmental projects.