Preferred for key projects, geomembranes lay a solid foundation for quality

Key Projects' First Choice: HDPE Geomembrane Liner Builds a Solid Quality Foundation

Global infrastructure is picking up speed these days, and quality and durability are the real priorities for all key projects. Think water conservancy projects that manage water supplies, environmental protection facilities keeping ecosystems balanced, transportation links connecting different regions, and municipal projects making daily life smoother—every single part needs dependable materials to lay a strong base. Among all the engineering materials out there, hdpe geomembrane liner has slowly become the go-to for key projects worldwide. It’s solid, performs consistently, and you just can’t do without it in modern construction.

The Core Demands of Key Projects for Impermeable Materials

Key projects usually link up with national development plans and people’s daily safety, so they’ve got really tough rules for material quality and performance. Impermeable materials are a big part of project protection—they stop leaks, protect the environment, and make projects last longer. Out in the field, when these materials are actually put to work, they have to handle tricky geological conditions, harsh weather, and constant pressure from years of use. So they need to hold up well, stop leaks effectively, and fit into different situations without issues.

Traditional impermeable materials are starting to hit their limits now that key projects want more. Some don’t stand up to corrosion—get damaged fast in acidic or alkaline environments, which leads straight to leaks. Others lack enough tensile strength; can’t handle when the project’s foundation shifts, causing cracks that mess up the whole project’s stability. That’s why hdpe geomembrane liner has gotten so much attention. It not only meets the strict anti-leakage needs of key projects but also stays reliable even in tough conditions. Long-term projects need that kind of guarantee.

Let’s be honest—picking the right impermeable material for key projects isn’t just about the project’s quality. It hits costs and environmental protection too. A good impermeable material cuts down on maintenance costs later, stops pollution from leaks, and checks both economic and social boxes. hdpe geomembrane liner does all that, so engineers and decision-makers are trusting it more and more these days.

Material Advantages and Quality Assurance of HDPE Geomembrane Liner

hdpe geomembrane liner stands out in crowded markets for good reason—its top-notch performance and strict quality checks. HDPE is short for high-density polyethylene, a synthetic material with great physical and chemical properties. Geomembranes made from this stuff are strong, tough, and resistant to corrosion, so they work well in plenty of complex engineering settings.

When it comes to stopping leaks, hdpe geomembrane liner has extremely low permeability. Its tight molecular structure blocks water, oil, chemicals, and other substances effectively. That means solid anti-leakage results for any project—reservoirs, landfills, chemical storage tanks, you name it. Forms a reliable barrier that keeps harmful stuff from seeping into soil or groundwater, protecting the environment. Plus, it has high tensile strength and flexibility. Can handle foundation shifts and external impacts without breaking easily, keeping the project’s structure stable even when things move a little.

Quality for hdpe geomembrane liner also comes from strict production management and testing. Good manufacturers don’t cut corners on HDPE raw materials—go for high-purity stuff and use advanced equipment and processes to keep products consistent and dependable. Every batch goes through multiple tests—thickness checks, tensile strength tests, permeability tests—all to meet national and international standards. It holds up well against the weather too: sun, rain, extreme heat or cold—none of these wear it down quickly. Stays stable for years, which extends project lifespans by a lot.

Cross-Field Adaptability: Wide Application of HDPE Geomembrane Liner in Key Projects

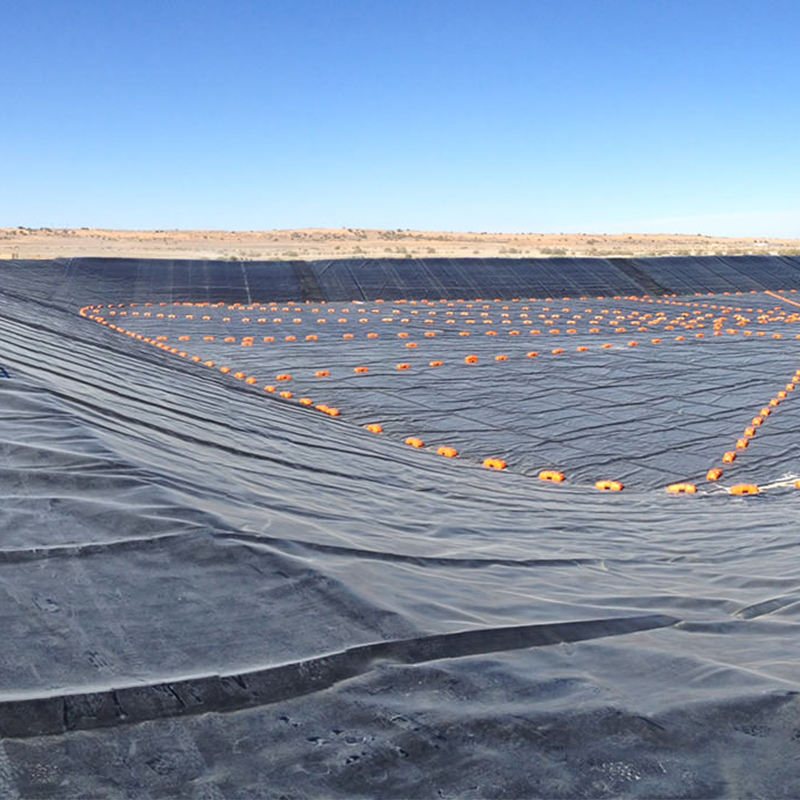

hdpe geomembrane liner’s strong adaptability lets it shine in all types of key projects—useful in so many areas. In water conservancy, you’ll find it in reservoirs, dams, and canals. Stops water from leaking, boosts storage capacity, and keeps water facilities running smoothly. In places where water is scarce, it cuts down on waste and makes water use more efficient. That’s a big deal for both farming and ecological protection.

In environmental protection projects, it’s a must-have. Landfills, sewage treatment plants, hazardous waste sites—all rely on it. Separates trash, sewage, dangerous waste from the surrounding soil and groundwater, preventing pollution. As global environmental standards get stricter, demand for hdpe geomembrane liner in these projects just keeps going up. It’s now a key part of keeping ecosystems safe.

In transportation infrastructure, you’ll find it all over roadbeds, railways, and airports. Stops water from eroding the ground under roads and railways, making them more stable and able to carry more weight. Means fewer problems like road subsidence or cracks. Works for municipal projects too—subways, underground pipelines—keeping them waterproof and leak-free. This ensures underground projects stay safe and last for years.

Quality Control System: Making HDPE Geomembrane Liner a Trusted Choice for Engineering

hdpe geomembrane liner’s reputation as a trusted choice for key projects comes from a full quality control system—from making the material to building with it. When picking raw materials, manufacturers screen HDPE carefully. Toss out low-quality stuff right away to make sure the final product performs well. Raw materials get strict tests too—purity, melt flow rate, all that basic stuff—to make sure they work for production.

During production, advanced tech and equipment are used for automated, smart manufacturing. Cuts down on mistakes from human hands. Production lines have real-time monitoring tools that track temperature, pressure, thickness, and other key factors. Keeps product quality consistent and stable. After production, every batch of hdpe geomembrane liner gets a full inspection. Only products that pass every test can leave the factory—keeps the pass rate really high.

Quality doesn’t stop once the geomembrane rolls off the production line, though. Building with hdpe geomembrane liner has strict rules too. Before starting work, the site needs cleaning and leveling. Sharp objects and debris that could tear the geomembrane have to go. During installation, pros stick to the plan tight. Lay the geomembrane flat (no wrinkles allowed) and make sure welding joints are strong and tight. After construction, the project goes through strict acceptance tests—air pressure tests, water pressure tests—to make sure the anti-leakage works as designed. This full quality control, from production to installation, makes hdpe geomembrane liner super reliable. That’s why key projects trust it.

Development Trends of HDPE Geomembrane Liner Under the Background of Industry Upgrading

Global infrastructure is growing nonstop, and environmental standards are getting higher all the time. For the hdpe geomembrane liner industry, that means new opportunities and challenges alike. In the future, hdpe geomembrane liner will keep getting more high-performance, eco-friendly, and smart. Manufacturers will keep tweaking formulas and processes, making the material even stronger and more corrosion-resistant to meet key projects’ stricter demands.

Eco-friendliness will be a big trend too. As people care more about the environment, manufacturers will focus on green raw materials and production methods. Cut down on energy use and pollution, and develop recyclable geomembrane products to keep things sustainable. Smart tech will shake up the industry too. For example, adding sensors to the geomembrane lets you monitor how it’s working in real time. It’s not uncommon to see this now—it makes spotting and fixing problems early easier, which makes projects safer and more reliable.

Demand for hdpe geomembrane liner is growing worldwide. Emerging markets in Asia, Africa, Latin America are speeding up infrastructure building—gives the industry a huge market to grow into. At the same time, more competition will push manufacturers to improve quality and service, helping the whole industry develop well. For key projects, the ongoing upgrades to hdpe geomembrane liner will mean even more reliable material support for high-quality construction.

Conclusion

In modern engineering, hdpe geomembrane liner has become an essential material for key projects. It’s solid, performs consistently, and fits so many uses—you can’t replace it. Helps keep projects durable, protects the environment, and supports sustainable infrastructure development. From water conservancy to environmental protection, transportation to municipal projects—hdpe geomembrane liner plays a key role everywhere, making it the first choice for key projects.

As industry tech advances and quality control gets better, hdpe geomembrane liner will keep improving. Its performance will get stronger, and it will be used in more areas. In the future, it will stay focused on quality, meeting new demands from key projects and contributing more to global infrastructure and environmental protection. For engineers and decision-makers, picking hdpe geomembrane liner isn’t just about getting quality or reliability—it’s also a choice that lines up with sustainable development and social responsibility.