Lightweight and Strongly Reinforced: Geocells Innovate Engineering Materials

Lightweight & High-Strength Reinforcement: HDPE Geocell Revolutionizes Construction Materials

The global construction and infrastructure space is shifting—slowly, but you can feel it, y’know? It really just boils down to needing materials that work smarter, hold up longer, and don’t bleed budgets dry. Urbanization’s picking up steam, and infrastructure projects are getting more of a hassle—rural road upgrades, slope stabilization, foundation reinforcement, whatever you throw at it. Traditional materials? They can’t keep up with both performance and practicality these days. Heavy concrete, clunky steel, organic stuff that wears out fast—they drag out build times, send costs sky-high, and mean never-ending maintenance. That’s why hdpe geocell’s blown up—no fancy jargon, just a material that delivers. This lightweight but tough-as-nails option is changing construction. It balances functionality, ease of use, and reliability in a way traditional materials rarely get close to.

The Limitations of Traditional Construction Materials

Construction folks have stuck to the same core materials for years to reinforce structures, stabilize slopes, and strengthen foundations. Concrete’s a workhorse, don’t get me wrong, but it’s way too heavy. Hauling 80-pound bags or pouring large slabs? Backbreaking, and costs add up quick—fuel, extra labor, lifts. It also doesn’t flex much—soil shifts or environmental stress, and it cracks easy. Patch it once, twice, and soon you’re redoing the whole thing. We had a rural county gig last year—they patched a concrete slope three times in two years. Total waste.

Steel fixes some issues but rusts, especially in humid or coastal areas. Salt air eats through it like nothing. We did a coastal bridge follow-up—steel rebar rusted through in 3 years, but nearby geocell? Still holding strong. You gotta keep up with maintenance, replace parts, and that bill grows over time. Who wants that hassle years after the job’s wrapped up? Seriously, it’s unnecessary.

Organic materials like wood are lightweight, sure, but they break down fast—moisture, pests, extreme temps. Most last a few years tops. We had a Texas client use wood stakes for slopes; termites chewed through ’em in 18 months. Even newer synthetics miss the mark—some strong but heavy, others light but flimsy after a year of sun and rain. These flaws force tough calls: slow down for strength, or cut costs but skimp on durability. As projects get bigger and budgets tighter, the need for a better material has only gotten more pressing. Ain’t no one got time for materials that create more work than they solve.

HDPE Geocell: Core Advantages

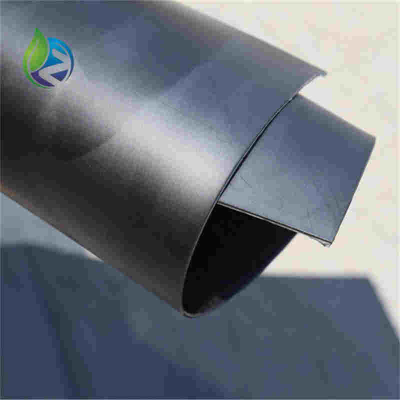

Hdpe geocell stands out because it hits the industry’s biggest pain points dead-on. It’s made from high-density polyethylene (HDPE)—a 3D cellular structure built to be light and tough. It flips how construction works on-site, no fancy setup needed.

Putting it in place is a breeze—way simpler than concrete or steel. It comes in compact rolls you can haul to remote sites, even tight-access dirt roads that can’t handle big trucks. Crews skip renting bobcats to move it—saves hundreds a day. Expand by hand or with small gear, no big machinery. Crews swear by tarping extra rolls—UV fries unrolled geocell fast. Pre-tensing it slightly before filling helps it lay flat, no weak-spot wrinkles. We’ve seen crews knock out 500 square feet in a couple hours—something that’d take days with concrete, maybe a week if weather’s crummy. That simplicity cuts labor costs and keeps projects on track—huge for tight deadlines, which most jobs have.

Another standout is its weight-to-strength ratio. It’s 80% less dense than concrete—no big rigs needed, saving time and money. But don’t let the light weight fool you—it has serious tensile strength and handles heavy loads, thanks to its cellular design. Expand it, fill cells with soil or gravel, and weight spreads evenly. No more stress piles, settlement, or surprise cracks six months later.

It’s flexible too, unlike rigid concrete or steel. It adapts to small soil movements and terrain changes without breaking. That’s key in erosion-prone areas, earthquake zones, or places with big temperature swings—where rigid materials fail hard. We did a Minnesota rural road job with winter freeze-thaw cycles; concrete would’ve cracked in a year, but geocell’s still going strong. It resists UV, chemicals, and decay, so it lasts. Most products hang in there 20-30 years easy—way longer than organics, and right up there with well-maintained steel (which rarely stays that way).

Key Applications

Hdpe geocell is versatile as all get-out, so it’s a go-to for all kinds of infrastructure projects. From small residential foundations to large-scale jobs, it adapts to different terrains and needs. It’s not just basic reinforcement anymore—it solves real-world problems.

Road crews lean hard on it, especially for weak subgrades. Rural counties love it—no budget for heavy equipment or constant repaving. We worked with a county that used to repave 10 miles every two years; now, with geocell, it’s five years and counting. It cuts rutting, cracking, and settlement, extending road life and lowering maintenance costs. Plus, it’s light, so less excavation and backfilling—easier on the environment.

Slope stabilization is where it shines. Steep slopes (natural or man-made) erode or slide, risking structures and ecosystems. We had an Atlanta hillside job—slopes eroded every rainy season, mud oozing into basements, trees toppling. Installed geocell, filled with local soil and grass seed, and now? No more mud, no more fallen trees. It creates a stable, erosion-resistant surface that holds infill and helps plants grow—win-win. Perfect for highway embankments, railway cuttings, coastal protection.

Foundation reinforcement is another critical use. Weak soil causes uneven settlement, damaging buildings and bridges. We had a Florida client building on reclaimed land—traditional concrete footings needed 3 feet of gravel and steel, costing a fortune. Geocell cut that to 1 foot, chopping costs by tens of thousands. It spreads weight evenly, reducing pressure on weak spots.

Don’t forget waste containment. Hdpe geocell resists chemicals and decay, making it great for landfills and containment ponds. It stops harmful substances leaking into soil and groundwater—big for EPA compliance. Its cellular structure reinforces landfill caps, reducing erosion and extending facility life. We did an Ohio landfill cap 10 years ago—still no erosion, no leaks.

Sustainability & Tech Improvements

The construction industry is moving toward sustainability, and hdpe geocell fits right in. Producing it uses way less energy than concrete or steel. HDPE is recyclable, so smaller environmental footprint. Unlike wood, making it doesn’t require cutting natural resources—more eco-friendly. We had a California client get a sustainability tax break just for using geocell instead of concrete.

Its long lifespan helps too. Traditional materials need maintenance or replacement every 5-10 years, wasting resources. Geocell’s durability means fewer materials over time, cutting carbon emissions—something clients and regulators care about. It also supports erosion control and plant growth, improving biodiversity. No more bare slopes washing away—now you have green, stable ground.

For contractors, sustainability means economic benefits—incentives, certifications, tax breaks. Geocell’s long life cuts maintenance costs and extends infrastructure life. It’s not just “green for show”—it makes business sense, so more teams are switching.

Tech improvements make it even better. Manufacturers tweak production nonstop—better extrusion processes cut costs, automated quality control ensures consistency (no duds anymore). Modern geocell has additives boosting UV resistance, chemical stability, and tension tolerance—works in 115-degree Arizona deserts or freeze-thaw northern regions. Early geocell was a one-trick pony; now manufacturers listen to our gripes and make specialized versions—high-temperature for landfills, flexible for earthquake zones. Design improvements mean more cell sizes and strengths—pick the perfect one for driveways or highway subgrades. Digital tools help too—design software models performance, cutting waste and saving time.

The Future & Conclusion

As construction evolves, hdpe geocell will only grow more popular. Demand for efficient, eco-friendly, budget-friendly materials is rising—clients ask about it upfront now. Add tech advancements, and it’ll pop up in more projects, more places.

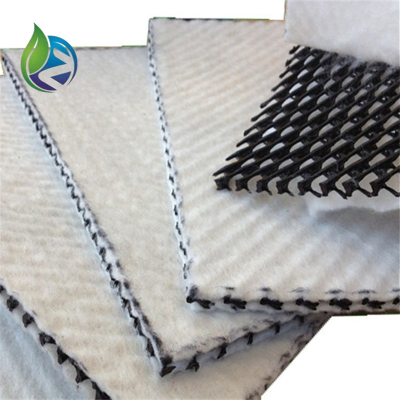

Growing economies in Asia, Africa, and Latin America need affordable, easy-to-install reinforcement. Geocell’s low cost, light weight, and durability make it perfect—we’ve heard from Brazilian and Indian contractors who say it makes tough jobs manageable. Engineers are mixing it with geotextiles or geogrids for stronger hybrid systems, already used on high-speed rail, stadiums, and bridges. Sustainability will drive innovation—better recyclability, lower energy production, bio-based HDPE. Smart infrastructure will bring new opportunities too—sensors in geocell let engineers monitor in real time, catching issues weeks before they become major problems.

Hdpe geocell isn’t just another new material—it’s changing how we build. It offers a unique mix of light weight, strength, durability, and sustainability. By fixing traditional materials’ flaws—weight, rust, short lifespan, high costs—it’s become a go-to for roads, slopes, foundations, and waste containment.

It’s easy to install, cost-effective, and long-lasting—valuable for contractors and owners alike. It fits green trends, making it a material for the future. Ongoing tech improvements will keep it versatile, expanding its use. The construction industry faces big challenges: urbanization, climate change, limited resources. Hdpe geocell is key to building more resilient, efficient, and sustainable infrastructure. It’s a new way of thinking—prioritizing performance without compromises. For anyone wanting better results with fewer resources, hdpe geocell isn’t just a solution—it’s a game-changer. Plain and simple.