Small grilles, great achievements, adding confidence to infrastructure safety

Small Grids, Big Impact: Fiberglass Geogrid Boosts Infrastructure Safety

Hardly anyone spares ’em a glance, but some of the most critical materials in infrastructure construction are the “invisible” ones. Roads, slopes, tunnels, underground jobs—they all need bits that can stand rough conditions, take a beating and not wear out, keep holding things up reliably. And let’s be real—none of this can cost an arm and a leg, y’know? Fiberglass geogrid is one of these unsung heroes. It’s proven that even small, lightweight gear can make a massive difference when it comes to reinforcing infrastructure. This article breaks down how this flexible stuff is changing the way we build, fixing common headaches, giving engineers and project managers the confidence to create structures that’re safer, last way longer than old-school builds.

The Growing Demand for Reliable Reinforcement in Modern Infrastructure

Modern infrastructure’s under more pressure than ever—no sugarcoating it. Cities are spreading out, so we need more roads, bridges, underground systems. At the same time, climate change is throwing extreme weather our way—heavy downpours, wild temperature swings—that pushes old-school construction materials to their limit, sometimes way past it. Roads get potholes, cracks, slopes wash away, underground structures shift with the soil. All this leads to expensive repairs, messed-up daily routines, even safety risks. So the construction industry’s always hunting for materials that make things more stable, last longer, cut down on maintenance. Can’t slow work down, can’t trash the environment either.

Fiberglass geogrid? It stands out because it goes right at these problems—no beating around the bush. Old reinforcement materials? They’re full of downsides—heavy, rust easy, or a total nightmare to get installed on-site. But this game-changing stuff blends strength, flexibility, and staying power in a way that fits what modern construction actually needs. Spreads weight out nice and even, holds up pretty well over time—better than a lot of alternatives, let’s be honest—and works smooth with other materials. That’s why engineers reach for it when they want to upgrade infrastructure. Expanding a highway, fixing a rural road, stabilizing a slope—doesn’t matter. It’s a reliable solution that performs when it counts: out in real-world conditions, not just some lab.

Core Advantages of Fiberglass Geogrid: Strength Meets Versatility

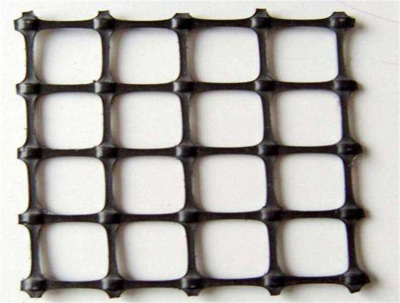

Fiberglass geogrid’s blown up for good reason—it has traits that make it perfect for reinforcement work. Here’s the thing: strong fiberglass threads woven into a grid. Then it’s coated with a protective layer, usually polyethylene or polypropylene, that keeps it safe from chemicals, sun damage, scratches. This design gives it a unique balance of strength and flexibility that beats a lot of other materials out there.

One thing that really sticks out with fiberglass geogrid is how tough it is when you pull it—seriously, it’s lightweight but can handle a ton of pulling force. Way more than you’d guess for something so thin. That’s why it’s great for stabilizing soil, stopping it from shifting around. That strength matters a lot in road building—you lay it between the base layer and the asphalt, sometimes right into the asphalt itself. When cars and trucks drive over, it spreads the weight out over a bigger area. So the soil and pavement underneath don’t get overstressed in one spot. Stops ruts from forming, keeps cracks to a minimum. Unlike steel reinforcement, it doesn’t rust when wet or exposed to chemicals. Keeps working well for decades—decades, mind you—even in damp, harsh places.

And hey, another win: it’s flexible, super easy to install. Lightweight, so field crews don’t gotta heave those bulky rolls around all shift. Slashes labor costs a bit, gets the job done faster. You can cut it to the size you need right on the job site, so it fits whatever the project requires. Sticks well to other construction materials too, so it blends right into the whole structure. Plus, it bounces back nice and easy—even when it’s getting stressed over and over, like from constant traffic or soil shifting, it keeps its shape and strength. All these things—toughness, longevity, how simple it is to work with—make it a cost-effective choice that pays off in the long run. Guys out in the field swear by it—not just office folks—no back-breaking hauls like you get with steel.

Fiberglass Geogrid in Road Construction: Paving the Way for Durability

Roads take a serious beating: constant traffic, rain, snow, soil shifting right under ’em. Old-school pavements start cracking, getting potholes, ruts after just a few years. Means you’re always out there fixing ’em, which sucks up time and money. Fiberglass geogrid has changed road construction by offering a simple, effective way to make pavements last way longer, work way better.

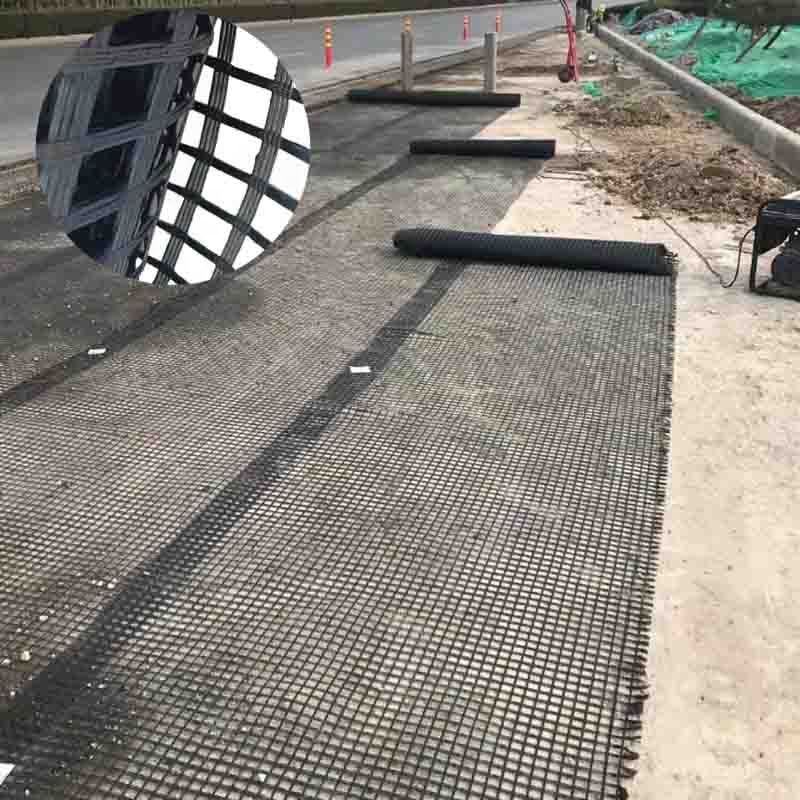

In road projects, fiberglass geogrid is usually placed between the base course and the asphalt layer, sometimes inside the asphalt. When traffic rolls over, the material acts as a reinforcement layer. Spreads the weight out wider, so the soil and pavement underneath don’t get too much pressure in one spot. Stops local damage like ruts, soaks up the tension that causes cracks. The end result? A road that can handle more traffic, doesn’t get damaged as easy from temperature changes, rain, wear and tear.

One of the best things about using fiberglass geogrid in roads is less maintenance. Roads reinforced with this material don’t need repairs as often. Saves government agencies, private contractors time and money. And since it doesn’t rust or get fried by the sun, it keeps working well for decades—no need to replace it often. This is especially helpful for rural areas, places with small maintenance budgets. Means roads stay safe, usable for longer without big investments.

Truth is, it makes road building more green too—who’d have thought? By making pavements last longer, we don’t need as many new materials or as much construction work. Cuts down on the carbon footprint of infrastructure projects. The material itself is kind to the planet—non-toxic, you can recycle it when it’s done being used. As the construction industry moves toward greener practices, fiberglass geogrid is a way to keep performance high while not trashing the environment.

Stabilizing Slopes and Protecting Ecosystems with Fiberglass Geogrid

Slope issues? Total nightmare for infrastructure work—especially hilly or coastal areas. Unstable slopes can cause landslides. These damage roads, buildings, natural habitats, and they’re a serious safety risk. Traditional ways to stabilize slopes—like retaining walls or covering ’em with truckloads of rock—are often expensive, take a lot of work, trash the environment. Fiberglass geogrid is a better, more affordable option. It not only stabilizes slopes, but helps restore ecosystems too.

When used for slope stabilization, fiberglass geogrid is installed along the slope. Sometimes buried in the soil, other times covered with plants. The grid’s high tensile strength stops the soil from sliding down, prevents erosion, landslides. Its open design lets water drain through easy. That’s important—too much water buildup can weaken slopes over time, make ’em prone to giving way. And hey, the grid gives plants a solid base to take root in. Plant roots can grow through the openings, hold onto the soil, which makes the slope even more stable.

Fiberglass geogrid is perfect for ecological restoration projects. Unlike concrete or steel structures, it doesn’t disrupt natural habitats. Lets native plants grow, helps restore the slope’s ecosystem. Supports more wildlife, reduces the impact of construction on nature. For example, in coastal areas where erosion is a problem, fiberglass geogrid can stabilize sand dunes. At the same time, it lets grasses and other plants grow, creates a natural barrier against storms, waves.

Another good thing about using fiberglass geogrid for slopes: it works in different terrain, soil types. Slope’s steep or gentle, made of sand, clay, or rock—you can adjust the material to fit the project. It’s light, so easy to transport, install in remote or hard-to-reach areas. No need for heavy machinery, which means less disturbance to the surrounding environment. With its strength, green factor, ease of use, fiberglass geogrid has become a top choice for slope stabilization projects all over the world. Contractors who’ve used it say it’s way less of a hassle than the old ways—no giant concrete pours or hauling endless truckloads of rock.

Enhancing Underground Engineering Safety with Fiberglass Geogrid

Underground infrastructure—tunnels, subway systems, utility corridors—comes with its own set of unique challenges. Below ground, it’s all high pressure, moisture, constant soil shifting. These structures need materials that can handle constant stress, resist corrosion, provide reliable support to prevent collapse or damage. Fiberglass geogrid’s been a game-changer for underground work—priceless, really. It offers the strength, durability needed to keep these structures safe for the long haul.

In tunnel construction, fiberglass geogrid is often used as a reinforcement layer in the tunnel lining. Applied to the inner surface—either embedded in concrete or attached to the rock face. This makes the lining stronger, more resistant to cracking. Tunnels face a lot of pressure from the soil and rock around ’em—sometimes enormous pressure. Fiberglass geogrid spreads out these forces evenly, lowers the risk of structural failure. It also doesn’t get damaged by moisture or chemicals, so it keeps working even in damp, corrosive underground environments.

For underground utility corridors and pipelines, fiberglass geogrid stabilizes the soil around the structures. Prevents settlement, movement that can cause leaks or damage. The material is placed in the trench before the pipelines or utility lines are installed. Creates a stable base that supports the weight of the soil, resists side pressure. This protects the infrastructure from damage caused by erosion, sinking, even earthquakes. Ensures essential services—water, gas, electricity—keep running nice and smooth.

Let me break it down: fiberglass geogrid makes underground installations more efficient too. It’s light, flexible, so easy to handle in tight spaces. Cuts down on the time and labor needed for installation. Unlike heavy steel reinforcement, which is hard to move around underground—total pain in tight spots—fiberglass geogrid can be rolled out, cut to size on the spot. Fits the unique dimensions of each project. This not only speeds up construction but makes the work safer in confined spaces—something workers on the ground really appreciate. After all, no one wants to lug heavy steel through a tight tunnel.

The Future of Infrastructure: Fiberglass Geogrid Driving Innovation

Global demand for safe, sustainable, resilient infrastructure is growing—and fast. Fiberglass geogrid is set to play an even bigger role in shaping the future of construction. Engineers and manufacturers—they’re always tweaking the material to make it better. Developing new formulas, designs that boost its strength, durability, flexibility. High-performance coatings that handle extreme temperatures better—hot or cold. Advanced weaving techniques that improve how it spreads out weight. These tweaks are unlocking more uses for fiberglass geogrid, turning it into an even more useful tool for infrastructure jobs.

One big trend in the industry is combining fiberglass geogrid with smart technology. Researchers are looking into embedding sensors in the material. These sensors can monitor stress, temperature, moisture in real time. Give engineers important data about how infrastructure is performing. This lets them do maintenance proactively. Instead of waiting for a problem to get worse, they can fix it early. For example, sensors in a road reinforced with fiberglass geogrid could detect small cracks before they turn into big potholes. Contractors can then make repairs before the damage spreads—saves time and money in the long run. Crazy how tech’s turning these classic materials into something even more useful.

And another trend is focusing on sustainability. The construction industry is working hard to reduce its environmental impact. Fiberglass geogrid is becoming more popular because it has a low carbon footprint, can be recycled. Manufacturers are using more eco-friendly materials in production. And since the material lasts so long, it cuts down on the need for frequent replacements. Saves resources, reduces waste. Also, fiberglass geogrid helps with ecological restoration—like growing plants on slopes. This lines up with the growing focus on green infrastructure.

The global market for fiberglass geogrid is expanding too. Emerging economies are building more infrastructure. Developed countries are fixing old roads, bridges, tunnels—stuff that’s been around for decades and needs updating. Governments around the world are investing in critical structures. This creates a lot of demand for high-quality reinforcement materials. As engineers and project managers learn more about the benefits of fiberglass geogrid, more projects will use it. This will lead to safer, more durable, more sustainable infrastructure everywhere.

Conclusion

In infrastructure construction, fiberglass geogrid may be small, but its impact is huge. This flexible, high-performance material has changed how engineers approach reinforcement. It offers a mix of toughness, longevity, green benefits, ease of use that’s hard to beat. From roads and slopes to tunnels and underground projects, fiberglass geogrid provides the support needed to keep infrastructure safe, long-lasting. Cuts down on maintenance costs, minimizes environmental harm—two things that matter more than ever these days.

As demand for reliable, resilient infrastructure grows, fiberglass geogrid will become even more essential. It solves key problems—soil movement, erosion, corrosion, wear—that plague construction projects. It’s a valuable tool for engineers who want to build safer, greener structures. New construction or fixing old infrastructure—either way, fiberglass geogrid proves that small materials can deliver big results. Gives infrastructure the strength it needs to stand the test of time.

At the end of the day, infrastructure safety is crucial. Fiberglass geogrid is more than just a construction material. It’s a promise to build a better, more resilient future. As technology advances, innovations keep coming, this unsung hero of the construction industry will play an even more important role in shaping the infrastructure of tomorrow. For anyone in the construction game building stuff that’s supposed to last, fiberglass geogrid isn’t some fancy add-on—it’s a no-brainer. Honestly, you can’t miss with it. Works for projects, communities, and the planet too.