How many kinds of geogrid can we offer?

Product Definition of Geogrid

Geogrid is a polymer-based geosynthetic material engineered with a regular grid structure to reinforce soil and aggregate systems. It improves load distribution, tensile resistance, and long-term stability in civil, mining, transportation, and infrastructure engineering applications.

How Many Kinds of Geogrid Can We Offer?

From an engineering and supply perspective, geogrids are generally classified into several standardized categories based on structure, material, and load direction. Understanding how many kinds of geogrid can we offer helps EPC contractors, designers, and procurement teams match performance requirements with project conditions.

Main Categories of Geogrid

Triaxial Geogrid

Polyester (PET) Geogrid

Steel-Plastic Composite Geogrid

Technical Parameters and Specifications

The following parameters are commonly used in engineering specifications and tenders when evaluating how many kinds of geogrid can we offer for a project:

Raw material: HDPE, PP, PET, fiberglass, steel-plastic composite

Tensile strength: 20–200 kN/m (depending on type)

Elongation at break: ≤10% (PET), ≤15% (HDPE/PP)

Aperture size: 20 × 20 mm to 65 × 65 mm

Creep reduction factor: ≤1.4 (PET geogrid)

Design life: ≥50 years in buried conditions

Roll width: 3.9–6.0 m (customizable)

Structure and Material Composition

Different answers to how many kinds of geogrid can we offer originate from variations in structure and material composition:

Uniaxial Geogrid: High-strength ribs oriented in one direction for slope and retaining wall reinforcement

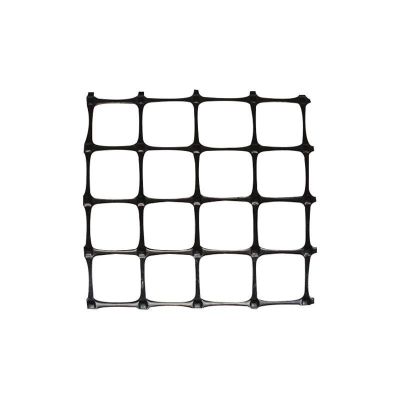

Biaxial Geogrid: Balanced tensile strength in longitudinal and transverse directions

Triaxial Geogrid: Triangular aperture structure for multidirectional load transfer

Fiberglass Geogrid: Alkali-resistant glass fibers with polymer coating

PET Geogrid: High-modulus polyester yarns with PVC or bitumen coating

Steel-Plastic Geogrid: Steel wires encapsulated in polyethylene

Manufacturing Process

The manufacturing process determines how many kinds of geogrid can we offer with stable and repeatable performance:

Raw material preparation: Polymer pellets, fibers, or steel wire inspection

Extrusion or weaving: Sheet extrusion (HDPE/PP) or warp knitting (PET/fiberglass)

Punching and stretching: Controlled stretching to orient molecular chains

Coating process: PVC, bitumen, or polymer coating for durability

Quality testing: Tensile, creep, junction efficiency testing

Roll forming and packaging: Standardized rolls for logistics

Industry Comparison

| Material | Tensile Strength | Creep Resistance | Typical Application |

|---|---|---|---|

| Geogrid | High | Excellent | Roads, slopes, retaining walls |

| Geotextile | Medium | Moderate | Separation, filtration |

| Steel Mesh | Very High | Low (corrosion risk) | Temporary reinforcement |

| Concrete | Rigid | N/A | Structural support |

Application Scenarios

Understanding how many kinds of geogrid can we offer allows stakeholders to select the correct solution for:

Road and highway base reinforcement

Railway subgrade stabilization

Mining haul roads and tailings dams

Retaining walls and steep slopes

Port, airport, and industrial platforms

Core Engineering Pain Points and Solutions

Uneven settlement: Solved by biaxial or triaxial geogrid load distribution

Slope instability: Addressed using high-strength uniaxial geogrid

Long-term creep: PET geogrid with low creep factors

Corrosion concerns: Polymer-coated or fiberglass geogrid solutions

Risk Warnings and Mitigation

Avoid mismatching tensile direction and load direction

Verify chemical resistance in aggressive soil environments

Ensure correct overlap and anchoring during installation

Confirm compliance with project design standards

Procurement and Selection Guide

Clarify load direction and design tensile requirements

Identify soil type and environmental exposure

Confirm design life and creep limits

Select geogrid type accordingly

Request laboratory test reports

Conduct trial installation if necessary

Engineering Application Case

In a mining haul road project, a biaxial HDPE geogrid with 40 kN/m tensile strength was installed between subgrade and aggregate layers. The reinforced section reduced rutting by over 35% and extended maintenance intervals, demonstrating how different answers to how many kinds of geogrid can we offer translate into engineering value.

FAQ

Q1: How many kinds of geogrid can we offer for road projects?

A: Typically uniaxial, biaxial, triaxial, and PET geogrids.Q2: Which geogrid has the lowest creep?

A: PET geogrid.Q3: Are geogrids customizable?

A: Yes, in strength, aperture, and roll size.Q4: Can geogrids be used in mining?

A: Yes, especially for haul roads and tailings dams.Q5: What is junction efficiency?

A: The strength of rib intersections.Q6: Are fiberglass geogrids alkali resistant?

A: Yes, with proper coating.Q7: How long is the service life?

A: Typically over 50 years.Q8: Can geogrids replace concrete?

A: They complement, not replace, rigid structures.Q9: Do standards vary by region?

A: Yes, ASTM, ISO, and EN standards apply.Q10: Is on-site supervision required?

A: Recommended for large EPC projects.

CTA

For detailed specifications, engineering drawings, or project-based quotations related to how many kinds of geogrid can we offer, please request technical documentation or engineering samples through formal procurement channels.

E-E-A-T Author Statement

This article is prepared by a technical engineering team with over 15 years of experience in geosynthetics manufacturing, testing, and EPC project support, providing evidence-based guidance aligned with international civil engineering standards.