How to Choose Geomembrane

How to Choose Geomembrane: A Comprehensive Guide

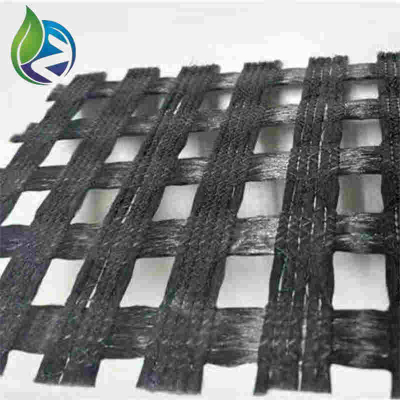

When it comes to civil engineering projects, environmental protection, and infrastructure development, geomembranes play a crucial role in preventing water or chemical leakage. These synthetic materials are used in a variety of applications, from landfill liners to pond liners and waterproof barriers. Choosing the right geomembrane can be a challenging task, as it depends on various factors, including the type of application, environmental conditions, and project requirements. In this article, we will guide you through the process of selecting the ideal geomembrane for your project, ensuring durability, cost-effectiveness, and optimal performance.

What is a Geomembrane?

A geomembrane is a synthetic, impermeable membrane typically used as a barrier to control the movement of water, waste, or chemicals in various engineering and environmental applications. These materials are commonly made from high-density polyethylene (HDPE), low-density polyethylene (LDPE), polyvinyl chloride (PVC), or other specialized polymers. Geomembranes are designed to resist the transmission of liquids and gases, making them an essential component for containment systems.

Factors to Consider When Choosing Geomembrane

Selecting the right geomembrane involves several considerations to ensure it meets your project’s needs. Below are key factors to consider when making your choice.

1. Material Type

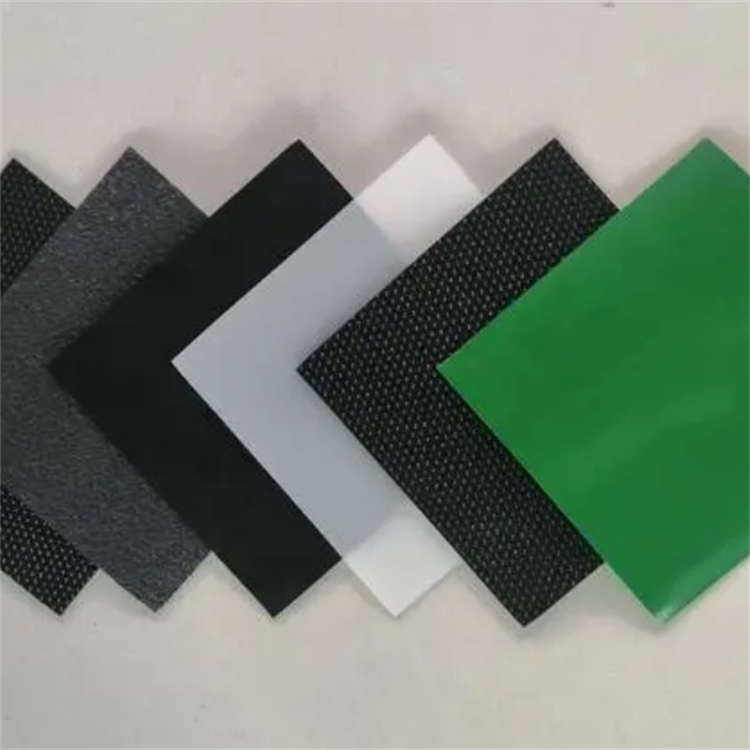

One of the first decisions you'll need to make when selecting a geomembrane is the type of material that will be best suited for your project. The three most common types of geomembranes include:

HDPE Geomembrane (High-Density Polyethylene): HDPE geomembranes are widely used due to their high chemical resistance, strength, and durability. They are ideal for applications such as landfills, mining operations, and water containment systems. HDPE is also known for its UV resistance, making it suitable for outdoor use.

LDPE Geomembrane (Low-Density Polyethylene): LDPE geomembranes are more flexible than HDPE and are typically used for applications that require a high degree of flexibility, such as pond liners, canal linings, and temporary water barriers.

PVC Geomembrane (Polyvinyl Chloride): PVC geomembranes offer excellent flexibility and weldability. They are commonly used in applications requiring high flexibility and ease of installation, such as agricultural ponds, water treatment facilities, and reservoirs.

Each material offers distinct advantages and is suitable for specific applications, so carefully consider your project's needs when choosing the material.

2. Thickness of the Geomembrane

The thickness of the geomembrane is an essential factor in determining its durability and suitability for the project. Thicker geomembranes provide increased strength and are more resistant to punctures, tears, and wear over time. For projects that involve exposure to high traffic or harsh environmental conditions, a thicker geomembrane will be necessary. Conversely, for less demanding applications, a thinner geomembrane might be sufficient.

A typical range of thickness for geomembranes is from 0.5 mm to 2.5 mm, depending on the material and the application requirements. Be sure to check the project specifications and consult with industry experts to determine the appropriate thickness.

3. Chemical Resistance

In many cases, geomembranes are used in environments where they may come into contact with hazardous chemicals, oils, or solvents. Therefore, chemical resistance is a critical factor when choosing the right geomembrane. Different materials have varying levels of resistance to chemicals, so you must evaluate the type of chemicals the geomembrane will be exposed to.

HDPE geomembranes are known for their excellent chemical resistance and are ideal for containment systems dealing with chemicals, petroleum products, and industrial waste.

LDPE geomembranes provide good chemical resistance but are less resistant than HDPE. They are suitable for agricultural or lower-risk applications.

PVC geomembranes offer resistance to a wide range of chemicals but may be less resistant than HDPE in extreme conditions.

Make sure to consult with the material manufacturer or supplier for detailed information on chemical resistance for the specific geomembrane you are considering.

4. UV Resistance and Weathering

If the geomembrane will be exposed to sunlight and harsh weather conditions, it is essential to choose a material with high UV resistance. UV radiation can degrade the material over time, leading to cracks and reduced performance. HDPE geomembranes are known for their superior UV resistance, making them ideal for outdoor use in areas with high sun exposure.

For indoor or less exposed applications, geomembranes with lower UV resistance may suffice. However, always ensure the selected material can withstand the conditions it will be exposed to during its service life.

5. Temperature Resistance

Temperature fluctuations can have a significant impact on the performance of a geomembrane. When exposed to extreme temperatures, some materials may become brittle or lose their flexibility, reducing their overall effectiveness. It is essential to choose a geomembrane that can handle the expected temperature range in your region.

HDPE geomembranes perform well in a wide temperature range, typically from -40°C to +60°C, making them suitable for most climates.

LDPE geomembranes are more flexible at lower temperatures but may not perform as well at extremely high temperatures.

PVC geomembranes can tolerate moderate temperatures but may not be suitable for areas with extreme heat.

6. Installation and Maintenance

Ease of installation is another important factor when selecting a geomembrane. Some materials are easier to handle and weld than others, which can significantly reduce installation time and costs. PVC geomembranes are often favored for their ease of welding and installation. They can be easily seamed using hot-air welding or solvent welding.

Additionally, consider the long-term maintenance requirements of the geomembrane. HDPE geomembranes are known for their durability and require minimal maintenance. In contrast, other materials like PVC may require more frequent inspections or repairs depending on environmental exposure.

7. Environmental Impact and Sustainability

Sustainability is an increasingly important consideration in construction and environmental projects. Many geomembranes are made from recyclable materials, and selecting a product with minimal environmental impact is essential for eco-conscious projects. HDPE geomembranes, for example, are fully recyclable and can be reused in future projects, making them a sustainable choice.

If environmental impact is a primary concern for your project, seek out manufacturers that prioritize eco-friendly materials and recycling programs.

Conclusion

Choosing the right geomembrane is critical for the success of your project. By considering factors such as material type, thickness, chemical resistance, UV resistance, temperature tolerance, installation ease, and environmental sustainability, you can ensure the geomembrane will provide long-lasting protection and perform effectively under the given conditions. Whether you are working on a landfill project, pond lining, or other containment systems, selecting the appropriate geomembrane will help ensure that your project is safe, cost-effective, and environmentally responsible.