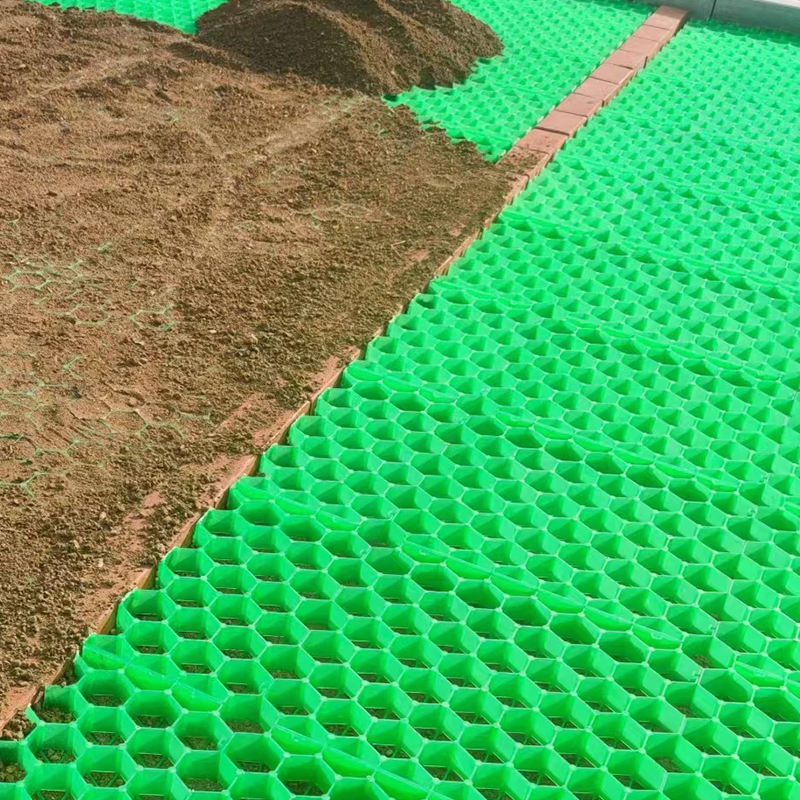

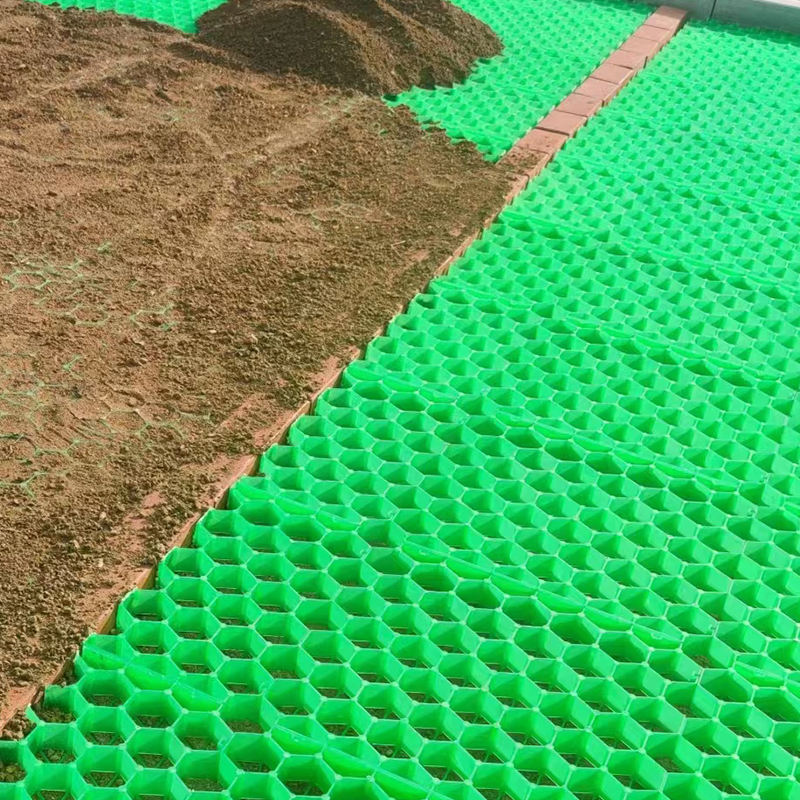

Grass Pavers: Bearing Weight and Greening, Achieving Two Goals at Once

Product Definition

Grass pavers are modular load-bearing ground reinforcement systems designed to support vehicular and pedestrian traffic while enabling grass growth and natural water infiltration. They combine structural strength with ecological surface treatment, making them suitable for sustainable infrastructure, parking areas, and landscape engineering projects.

Technical Parameters and Specifications

Engineering-grade grass pavers must balance mechanical performance and environmental adaptability. Typical technical parameters include:

Material types: HDPE, PP, reinforced concrete

Compressive strength: 160–350 t/m² (filled condition)

Single unit size: 400 × 400 mm to 500 × 500 mm

Thickness: 38–70 mm

Void ratio: 30%–50%

Water permeability coefficient: ≥1 × 10⁻² cm/s

Operating temperature range: -30°C to +70°C

Design service life: ≥20 years (plastic), ≥30 years (concrete)

Structure and Material Composition

Grass pavers are engineered with an optimized geometry to ensure both load transfer and vegetation survival.

Top Load Distribution Grid: Transfers vertical loads laterally

Cellular Void Structure: Holds soil and turf while allowing drainage

Bottom Support Layer: Enhances contact with base course

Interlocking Edges: Improve overall system stability

Polymer or Concrete Matrix: Provides durability and resistance to deformation

Manufacturing Process and Engineering Controls

Manufacturing Workflow

Raw material selection and quality inspection

Injection molding (plastic) or precast forming (concrete)

Structural rib reinforcement shaping

Controlled cooling or curing process

Dimensional accuracy inspection

Mechanical performance testing

Key Equipment and Process Points

Production relies on high-tonnage injection molding machines or precision concrete molds. Critical controls include rib thickness uniformity, void geometry accuracy, and compressive strength consistency to ensure reliable performance under traffic loads.

Industry Comparison: Surface Reinforcement Solutions

| Solution Type | Load Capacity | Permeability | Greening Effect | Typical Applications |

|---|---|---|---|---|

| Grass Pavers | High | Excellent | High | Parking, fire lanes |

| Concrete Pavement | Very High | Low | None | Urban roads |

| Asphalt Pavement | High | Low | None | Traffic roads |

| Permeable Bricks | Medium | Medium | Low | Walkways |

Application Scenarios and Users

Grass pavers are widely applied in:

Municipal and commercial parking areas

Fire access roads and emergency lanes

Residential community roads

Industrial park logistics zones

Ecological parks and green infrastructure

Typical users include EPC contractors, municipal engineering firms, landscape architects, developers, distributors, and infrastructure consultants.

Core Pain Points and Engineering Solutions

Pain Point 1: Ground Deformation Under Vehicle Load

Solution: Use high-strength grass pavers combined with compacted base layers to distribute loads evenly.

Pain Point 2: Poor Drainage and Water Accumulation

Solution: High void ratio structure ensures rapid infiltration and reduced surface runoff.

Pain Point 3: Loss of Green Coverage Over Time

Solution: Optimized cell depth protects root systems from compression damage.

Pain Point 4: Maintenance Cost and Surface Damage

Solution: Modular paver design allows localized replacement without full reconstruction.

Risk Warnings and Mitigation Recommendations

Risk: Insufficient base compaction

Mitigation: Ensure base layer compaction ≥95% Proctor densityRisk: Inappropriate soil infill

Mitigation: Use sand-soil mix with good permeabilityRisk: Heavy vehicle misuse beyond design load

Mitigation: Define load limits during planningRisk: Improper grass species selection

Mitigation: Choose wear-resistant turf varieties

Procurement and Selection Guide

Clarify traffic type and maximum axle load

Assess site soil and drainage conditions

Select material type (plastic or concrete)

Determine required compressive strength

Verify product testing reports and certifications

Review installation guidelines and technical support

Request samples for field evaluation

Engineering Case Study

In a municipal parking project serving emergency vehicles, HDPE grass pavers with a compressive capacity of 300 t/m² were installed over a graded crushed stone base. After three years of operation, the surface maintained structural integrity, achieved over 80% grass coverage, and showed no waterlogging during heavy rainfall.

Frequently Asked Questions (FAQ)

Q1: Can grass pavers support fire trucks?

Yes, when properly designed and installed.

Q2: Are grass pavers suitable for cold climates?

Yes, polymer pavers are frost-resistant.

Q3: How is drainage achieved?

Through interconnected void structures.

Q4: What base layer is recommended?

Compacted crushed stone or gravel.

Q5: Can grass pavers replace concrete pavement?

For light to medium traffic areas, yes.

Q6: How long do grass pavers last?

Typically 20–30 years depending on material.

Q7: Is maintenance complex?

No, routine lawn care is sufficient.

Q8: Do grass pavers reduce urban heat?

Yes, vegetation lowers surface temperature.

Q9: Are they environmentally compliant?

They support sustainable drainage systems.

Q10: Can damaged units be replaced individually?

Yes, modular design allows easy replacement.

Call to Action

For project-specific grass paver specifications, load calculations, technical drawings, or engineering samples, procurement and engineering teams are encouraged to request detailed technical documentation from qualified suppliers.

E-E-A-T: Author Expertise and Authority

This article is prepared by an infrastructure and geosynthetics engineering specialist with extensive experience in permeable pavement systems, municipal engineering, and sustainable ground reinforcement solutions for large-scale projects.