Environmental geotextiles, holding up the slope protection umbrella

Product Definition

Environmental geotextiles are permeable geosynthetic materials engineered to stabilize slopes, control erosion, and support vegetation growth. Acting as a protective umbrella, they reinforce soil structures while allowing water infiltration, effectively combining mechanical slope protection with ecological restoration in civil and environmental engineering projects.

Technical Parameters and Specifications

Environmental geotextiles used in slope protection must balance strength, permeability, and long-term durability.

Material types: PP, PET, biodegradable coir/jute blends

Mass per unit area: 100–800 g/m²

Tensile strength: 5–50 kN/m

Elongation at break: 15–80%

Water permeability: ≥10⁻³ m/s

CBR puncture resistance: 1.5–6.0 kN

UV resistance (retained strength): ≥70% after 500 hours

Service life: 5–50 years (material dependent)

Operating temperature range: -40°C to +60°C

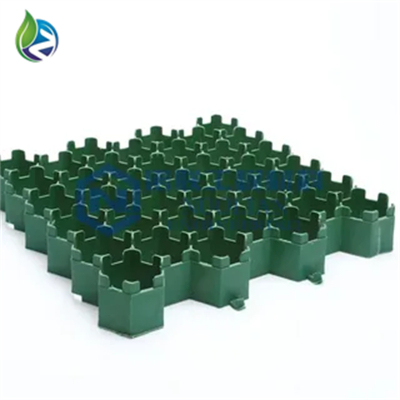

Structure and Material Composition

Environmental geotextiles are designed to integrate mechanical reinforcement with ecological compatibility.

Fiber Matrix Layer: Woven or nonwoven polymer fibers providing tensile strength

Porous Structure: Enables drainage and soil-water balance

Surface Texture: Enhances soil friction and root anchoring

UV-Stabilized Additives: Improve resistance to sunlight exposure

Optional Biodegradable Fibers: Support vegetation establishment

Manufacturing Process and Engineering Controls

Engineering Manufacturing Steps

Raw polymer or natural fiber selection

Fiber extrusion or preparation

Needle punching or weaving

Thermal bonding or chemical stabilization

Surface treatment and UV stabilization

Cutting, rolling, and packaging

Key Equipment and Process Control Points

Production utilizes extrusion lines, carding machines, needle looms, and tensile testing equipment. Quality control focuses on fiber uniformity, permeability consistency, and tensile performance to ensure reliable slope protection behavior.

Industry Comparison: Slope Protection Methods

| Method | Erosion Control | Ecological Compatibility | Construction Complexity | Typical Application |

|---|---|---|---|---|

| Environmental Geotextiles | High | Excellent | Low | Road, riverbank, embankment slopes |

| Concrete Shotcrete | Very High | Poor | High | Steep or high-risk slopes |

| Stone Riprap | High | Moderate | Medium | Riverbanks and coastal slopes |

| Vegetation Only | Low–Moderate | Excellent | Low | Gentle slopes |

Application Scenarios and Stakeholders

Environmental geotextiles are widely applied in:

Highway and railway slope protection

Riverbank and reservoir embankments

Landfill and mining site rehabilitation

Urban landscaping and green infrastructure

Soil erosion control in mountainous areas

Primary users include EPC contractors, civil engineering firms, environmental consultants, distributors, and infrastructure developers.

Core Pain Points and Engineering Solutions

Pain Point 1: Surface Soil Erosion During Heavy Rain

Solution: Geotextiles reduce runoff velocity and retain soil particles.

Pain Point 2: Poor Vegetation Survival on Slopes

Solution: Porous structure supports moisture retention and root anchoring.

Pain Point 3: High Construction Costs of Rigid Protection

Solution: Lightweight geotextiles simplify installation and reduce labor.

Pain Point 4: Long-Term Maintenance Challenges

Solution: Durable materials provide long service life with minimal upkeep.

Risk Warnings and Mitigation Measures

Risk: Insufficient anchoring

Mitigation: Use appropriate pins or trench anchorageRisk: UV degradation before vegetation cover

Mitigation: Select UV-stabilized products or rapid plantingRisk: Inadequate overlap between rolls

Mitigation: Maintain overlaps of ≥300 mmRisk: Clogging by fine soil

Mitigation: Match permeability to soil gradation

Procurement and Selection Guide

Assess slope gradient and soil conditions

Define erosion risk and hydraulic conditions

Select woven, nonwoven, or biodegradable geotextile

Confirm tensile strength and permeability requirements

Check compliance with environmental and engineering standards

Review laboratory test reports

Request samples and installation guidelines

Engineering Case Study

In a highway slope rehabilitation project, nonwoven PP geotextiles with 300 g/m² mass were installed beneath topsoil and hydroseeding. After two rainy seasons, surface erosion was reduced by over 60%, and vegetation coverage exceeded 90%, demonstrating effective combined mechanical and ecological protection.

Frequently Asked Questions (FAQ)

Q1: What is the main role of environmental geotextiles?

They control erosion while supporting vegetation growth.

Q2: Are geotextiles suitable for steep slopes?

Yes, when combined with anchoring systems.

Q3: Can biodegradable geotextiles be used?

Yes, for temporary erosion control and revegetation.

Q4: How long do synthetic geotextiles last?

Typically 20–50 years in buried conditions.

Q5: Do geotextiles block water flow?

No, they are designed to be permeable.

Q6: Is maintenance required?

Minimal maintenance once vegetation is established.

Q7: Can geotextiles be used with grass seeds?

Yes, they are commonly used with hydroseeding.

Q8: How are geotextiles fixed on slopes?

Using pins, anchors, or trenching methods.

Q9: Are they environmentally safe?

Yes, especially eco-friendly and biodegradable options.

Q10: Can geotextiles replace concrete protection?

They are an alternative for moderate erosion conditions.

Call to Action

For slope protection projects requiring both structural stability and ecological restoration, procurement teams are encouraged to request technical specifications, engineering guidance, or material samples from qualified environmental geotextile suppliers.

E-E-A-T: Author Expertise and Industry Authority

This article is written by a civil and environmental engineering specialist with extensive experience in geosynthetics and slope protection systems, providing reliable, engineering-driven insights for B2B decision-makers in infrastructure and environmental projects.