From Slopes to Subgrades: Geocells – One Material, Multiple Uses, Cutting Costs and Improving Quality in Infrastructure Projects

Product Definition

Geocells are three-dimensional cellular confinement systems manufactured from polymer sheets and welded into expandable honeycomb structures. When filled with soil, aggregate, or concrete, they provide load distribution, erosion control, and structural reinforcement for slopes, embankments, and subgrade engineering in infrastructure projects.

Technical Parameters and Specifications

Geocell performance depends on material grade, weld strength, and geometric configuration. Typical engineering-grade specifications include:

Material: High-Density Polyethylene (HDPE) or Novel Polymer Alloy (NPA)

Sheet thickness: 1.1–1.8 mm

Cell height: 50 / 75 / 100 / 150 / 200 mm

Weld peel strength: ≥ 1000 N/10 cm

Carbon black content: 1.5%–2.0%

Design life: ≥ 50 years (buried conditions)

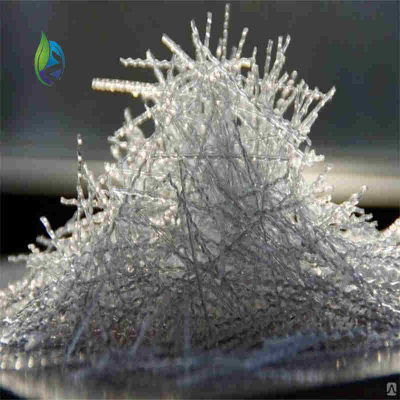

Structure and Material Composition

Geocells are engineered for confinement and load transfer through a modular structure:

Polymer sheet layer: Provides tensile strength and durability

Ultrasonic or thermal welds: Ensure cell integrity under load

Honeycomb geometry: Enhances lateral confinement

Infill material: Soil, sand, gravel, or concrete depending on application

Manufacturing Process

Geocell production follows controlled industrial steps to ensure consistency and engineering reliability:

Polymer extrusion into flat sheets

Precision sheet cutting and alignment

Automated ultrasonic or hot-melt welding

Quality inspection of weld strength and thickness

Folding and packaging for transport efficiency

Key equipment includes polymer extruders, CNC cutting machines, automated welding lines, and tensile testing devices.

Industry Comparison

| Material | Load Distribution | Erosion Control | Construction Cost | Design Flexibility |

|---|---|---|---|---|

| Geocells | Excellent | Excellent | Medium | High |

| Geogrids | Good | Moderate | Low | Medium |

| Concrete Slabs | Excellent | Low | High | Low |

Application Scenarios

Geocells are widely adopted across infrastructure sectors:

Road subgrades and base reinforcement

Slope stabilization and erosion control

Railway embankments

Port yards and container terminals

Temporary access roads for EPC projects

Core Engineering Pain Points and Solutions

Weak subgrade bearing capacity: Geocells distribute loads laterally

Slope erosion: Cellular confinement reduces soil loss

High aggregate consumption: Reduced fill volume by up to 40%

Construction delays: Modular installation accelerates timelines

Risk Warnings and Mitigation

Potential risks must be addressed during design and construction:

Incorrect cell height selection → Conduct load analysis

Low-quality welds → Require third-party testing

Inappropriate infill material → Follow geotechnical recommendations

UV exposure during storage → Use UV-stabilized materials

Procurement and Selection Guide

Define load and traffic class

Confirm soil conditions and CBR values

Select appropriate geocell height and thickness

Verify material certifications and test reports

Evaluate installation method and equipment availability

Request samples for field validation

Engineering Case Study

In a highway expansion project on soft clay subgrade, HDPE geocells (150 mm height) were installed with granular infill. Plate load testing showed a bearing capacity increase of over 2.5 times, while aggregate usage was reduced by approximately 35%, meeting EPC cost and schedule targets.

Frequently Asked Questions (FAQ)

Q1: Are geocells suitable for heavy traffic roads?

Yes, when properly designed.Q2: What infill materials are recommended?

Gravel, crushed stone, or stabilized soil.Q3: Can geocells replace traditional base layers?

In many cases, yes.Q4: What is the service life?

Typically over 50 years.Q5: Are geocells environmentally friendly?

They reduce material consumption and carbon footprint.Q6: Do geocells require skilled labor?

Basic training is sufficient.Q7: How are they transported?

Folded bundles for efficient logistics.Q8: Are geocells suitable for steep slopes?

Yes, with anchoring systems.Q9: Can they be combined with geotextiles?

Common practice in subgrade design.Q10: Is custom sizing available?

Yes, for project-specific needs.

Call to Action

For detailed technical datasheets, engineering samples, or project-specific quotations, please contact our technical sales team. Support is available for EPC bidding, value engineering, and construction optimization.

E-E-A-T: Author Credentials

This article is authored by a civil infrastructure materials specialist with over 15 years of experience in geosynthetics, highway engineering, and foundation reinforcement projects, supporting EPC contractors and consultants across transportation and municipal sectors.