Lightweight geocells solve construction challenges in complex terrains

Lightweight Geocells: Solving Construction Challenges in Complex Terrains

Construction projects in complex terrains—mountainous areas, hilly land, abandoned mines, uneven ground—always struggle with tough issues. Slope instability, subgrade settlement, tricky material transport, slow builds: these are daily headaches for engineering teams. Traditional fixes, like heavy concrete or stiff geosynthetics, rarely work. They’re a hassle to install, need lots of heavy gear, and can’t keep up with bumpy terrain’s changes. Lately, lightweight geocells have changed the game. Flexible, efficient, cheap—they hit these problems head-on. Tough but easy to handle, they’re redefining construction in hard landscapes, all while meeting modern engineering’s strict standards.

1. Core Challenges in Complex Terrains & Traditional Limits

Complex terrains throw unique hurdles at regular construction. First, slope erosion and instability are big risks. Mountainous or hilly areas get loose soil and frequent rain—landslides happen easily. This endangers workers and shortens project life. Traditional slope protection, like concrete walls, isn’t just costly—it’s rigid. Soil movement cracks or collapses them, leading to expensive fixes later.

Subgrade settlement is another big issue. Uneven, weak soil makes roads, railways, or foundations sink or shift over time. Heavy geogrids or gravel, once the main reinforcement, are hard to get to remote spots. Big trucks and gear add logistical stress and costs, especially where roads are narrow or access is poor. Hauling materials here is a pain—anyone who’s done it knows that.

Efficiency is also a worry. Traditional methods need lots of labor and time, delaying projects and raising costs. Plus, many regular materials have a big carbon footprint—bad for the growing demand for eco-friendly builds. Teams have sought a balance of performance, ease, and sustainability—and lightweight geocells fit.

When fixing these issues, geocell specifications matter. Older geocells work, but their rigid specs prioritize weight over flexibility. Bad for complex terrains where adapting is key. Lightweight ones? Their specs are built for uneven landscapes. Performance doesn’t mean losing maneuverability.

2. Design Advantages & How Lightweight Geocells Work

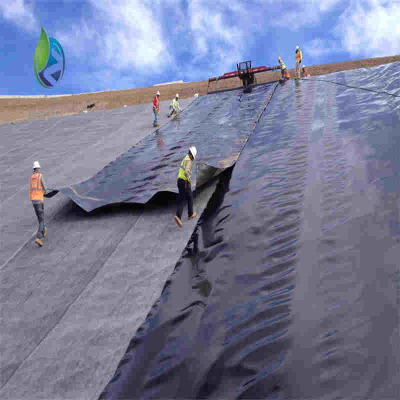

Lightweight geocells stand out for their smart design—tough, flexible, easy to use. Most use HDPE or PP: light, but resistant to UV, chemicals, and wear. Unlike heavy concrete or stiff geogrids, you fold them into small rolls. No need for big trucks—they reach remote areas even with poor infrastructure.

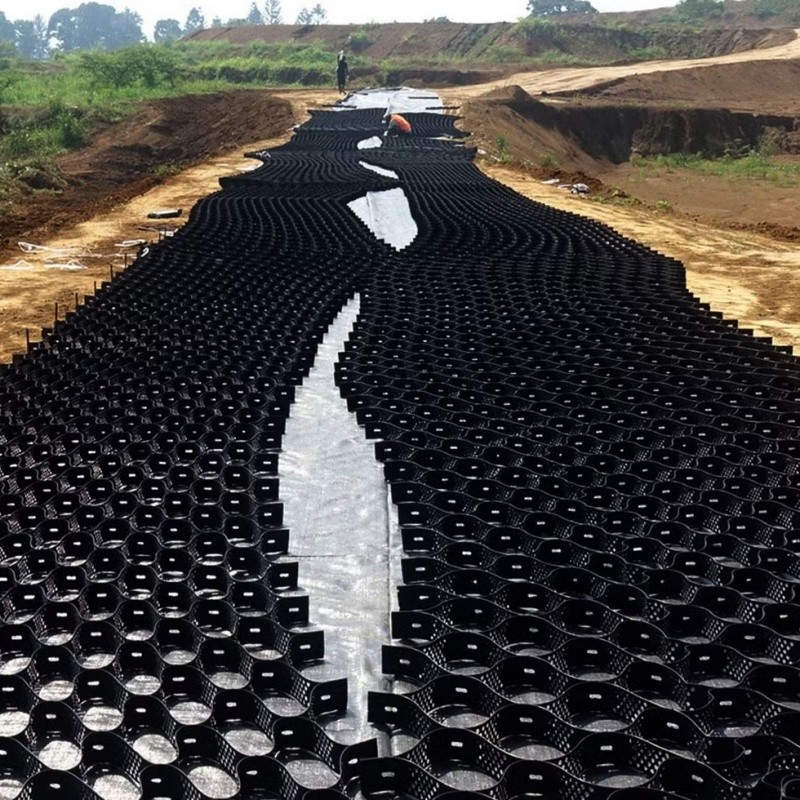

Their magic is in the cellular structure. Unfold, fill with local soil or gravel, and you get a 3D grid. It stabilizes ground by spreading weight evenly, stopping soil shift. Great for subgrades (cuts settlement, boosts load-bearing) and slopes (holds soil, lets plants grow—natural, eco-friendly landslide protection).

They’re versatile too—mountain roads, mine slope fixes, hilly residential foundations. Flexibility lets them follow uneven terrain’s shape, so you skip costly, time-consuming site leveling.

Geocell specifications for lightweight models are tweaked to boost these perks. Manufacturers balance thickness, cell size, tensile strength. They want easy handling but enough strength for tough terrain. For example: cell heights 50-300mm, tensile strength 10-20 kN/m. Reinforces soil well without extra weight. These specs match real construction needs—practical and reliable.

3. Performance: How Specs Fit Complex Scenarios

In complex terrains, geocell performance depends on specs. Every detail—material, cell size—changes how well they work. Lightweight ones focus on adaptability, durability, easy install—no strength loss.

Material is key for geocell specifications here. HDPE/PP are preferred: light, tough against harsh conditions. UV-stabilized, so they don’t break down in sun (common in mountains). Chemical-resistant, good for contaminated soil. No rust like steel or concrete—lasts decades, even wet or corrosive areas.

Cell size/shape matter too. Hexagonal or rectangular cells offer best stability and weight spread. Small cells (50-100mm) for slopes (hold soil tight). Larger ones (150-300mm) for subgrades (more fill, wider weight spread). Teams pick what fits—narrow mountain roads or steep slopes.

Tensile strength and modulus are critical specs. Lightweight geocells need to handle soil pressure and traffic without stretching or tearing. Good models have 10-20 kN/m tensile strength. They flex with soil movement, not crack—vital where ground shifts often. Stiff materials fail; these adapt.

Installation needs also shape geocell specifications. Easy-connect edges let workers assemble fast—no special tools. Cuts time and labor costs, huge for remote areas. Light weight means workers carry them to spots gear can’t reach. Even simpler to install.

4. Construction Optimization: Lightweight Design’s Impact

Lightweight geocells have transformed construction in complex terrains. They fix logistical and operational issues that slowed traditional methods. Every step—transport, install—is simpler, saving time, money, resources.

Transport is a big win. Traditional geosynthetics or concrete are heavy, bulky—need big trucks and gear. In tough terrain, this is a nightmare: trucks get stuck, roads damaged. Lightweight geocells? 10-20kg rolls. Move with small trucks, ATVs, even carry by hand. Cuts transport costs, lowers environmental impact—fewer trips, less fuel.

Installation shines too. Traditional slope or subgrade work needs lots of labor and gear. Concrete walls, for example, need on-site pouring—time and skilled workers. Lightweight geocells? Install in a fraction of the time. Unfold, connect with built-in locks, anchor with stakes. Fill with local soil/gravel/plants—hand tools or small gear work. Smaller teams, faster completion: lower labor costs, less downtime.

Scheduling gets flexible too. Complex terrains have unpredictable weather—rain, snow, fog delay work for days. Traditional materials need dry conditions. Lightweight geocells resist moisture—install in more weather. Quick installs mean progress even in short good-weather windows. Projects stay on track.

Geocell specifications drive this optimization. Easy-connect edges and light materials make install simple—no special training. Cell size fits local fill, so no hauling expensive aggregates far. Saves money, cuts carbon. Tensile strength and flexibility let installs on uneven ground—no extensive prep. Smoother construction all around.

5. Long-Term Value: Durability & Eco-Friendliness

Lightweight geocells offer immediate install/logistics benefits, but their real value is long-term: durable and eco-friendly, perfect for complex terrains.

Durability starts with geocell specifications. UV resistance, chemical protection, wear resistance—HDPE/PP doesn’t break down. Lasts decades. Cellular structure spreads stress evenly, less damage from soil movement or traffic. Projects need less maintenance—saves money and resources.

Eco-friendliness is a big plus. Traditional methods (concrete walls, asphalt) hurt the environment: disrupt drainage, stop plants, cause erosion. Lightweight geocells work with nature. Cellular structure lets plants grow—soil in cells feeds grass, shrubs. Roots hold soil, stabilizing slopes. They boost natural drainage, cutting waterlogging and erosion.

In sensitive areas (rivers, forests, wildlife habitats), this matters. Geocells minimize environmental impact, meet regulations, preserve landscapes. They support biodiversity—small animals and insects get habitats.

Geocell specifications boost both. UV-stabilized materials don’t leak toxins. Cell size/shape helps plants—larger cells let roots grow deep. Flexibility adapts to soil movement, less harm to nearby ecosystems. Balance of performance and sustainability—traditional solutions can’t match this long-term value.

6. Trends & Selection Tips

The construction industry cares more about efficiency, sustainability, and saving money. So lightweight geocells will be used more in complex terrains. Two big trends: demand for green infrastructure, and cost-cutting.

Green infrastructure is huge. Governments and owners want strict environmental standards. Lightweight geocells fit—plant-friendly, low carbon. They’re used for slope fixes, stormwater management: building sustainable, strong infrastructure.

Cost-cutting matters too. Competitive markets mean teams need on-time, on-budget projects. Geocells lower transport/install costs, need less maintenance, skip expensive materials (concrete, steel). Cost-effective for small rural roads to big builds.

When choosing, start with geocell specifications. Right material, cell size, tensile strength: small cells (high strength) for slopes, larger (better load-bearing) for subgrades. Pick easy-to-install ones—built-in locks, light weight.

Choose manufacturers with a solid history. They should follow standards (like ISO 9001) and share detailed specs/data. Ensures geocells work in complex terrains.

Think long-term. Immediate benefits are great, but pick durable, UV-stabilized geocells that adapt to terrain changes. This way, teams get safe, efficient, sustainable solutions.

Conclusion

Lightweight geocells are a game-changer for complex terrain construction. They fix slope instability, subgrade settlement, logistics, and environmental harm. Light materials plus durable cellular structure—flexible, efficient, sustainable, way better than traditional methods.

Geocell specifications focus on adaptability and strength, making transport/install easy. Long-term durability and eco-friendliness? Smart investment for any project size.

As construction evolves, lightweight geocells will play a bigger role in building strong, sustainable infrastructure. Pick the right ones, focus on specs that fit—teams beat complex terrain challenges. Safe, efficient, eco-friendly projects follow. For tough terrain builds, these geocells aren’t just a solution—they’re a practical tool that changes what’s possible.