Environmental Geotextile: Zero Pollution Protects Water Conservancy Slopes

Eco-Friendly Geotextiles: Zero-Pollution Protection for Hydraulic Slopes

For decades, civil engineering crews and environmental workers have fought to keep hydraulic slopes stable. You know the ones—riverbanks, reservoir edges, canal sides that cut right through towns. These slopes take a constant beating, no letup at all. Rain hammers ’em, water flows over, temperatures swing with the seasons. The old ways to protect ’em? Stuff like concrete liners or chemical waterproofing. Most of the time, they do more harm than good. Concrete traps moisture in the soil, so slopes crack way faster as the years add up. Those chemical products? They seep into nearby waterways, hurting fish, plants, the whole local ecosystem. And the worst part? These old methods need fixing or replacing nonstop. That means more construction noise, more waste, more mess for the environment. Now, the world’s shifting to greener infrastructure. Need something that works well and won’t pollute? That’s where eco-friendly geotextiles come in—just the perfect fit. Their ability to provide reliable waterproofing is changing how we protect hydraulic slopes—for good.

Hydraulic Slopes: The Hidden Costs of Outdated Protection

Hydraulic slopes aren’t just nice-looking parts of the landscape—they’re critical. They stop floods, protect farmland, keep water sources clean. But use old protection methods, and you put all that at risk. Take concrete. Seems tough at first, but it doesn’t let the soil “breathe.” After a couple years of rain, freezes, thaws, cracks start showing real bad. Once it cracks, water soaks into the slope. The soil loosens up, erosion sets right in. Sometimes, this even causes small landslides—ones that block water flow or damage nearby houses or businesses. Chemical waterproofing isn’t any better. A lot of these products have solvents that leak into the soil and mix with groundwater. They contaminate the very water we’re trying to keep clean. And those chemicals kill good microbes in the soil too. That makes it harder for native plants to grow—and plants are key to holding slopes together naturally. The cycle of fixing and replacing just makes things worse. Old concrete and chemicals end up in landfills. Every new installation means construction trucks burning more fuel. Hits budgets hard—same for the planet. That’s why eco-friendly geo waterproofing has been a real weight off for crews on slope jobs. It meets the performance needs without hurting the environment.

What Makes Eco-Friendly Geotextiles Different?

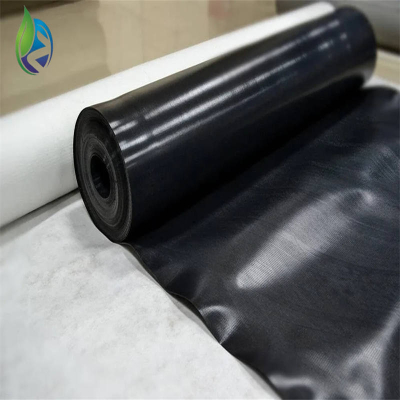

Eco-friendly geos aren’t just “greener” versions of the old stuff—they’re designed from day one to balance performance and sustainability. Most are made from recycled material—like polyester from old plastic bottles or leftover factory fibers. This does two good things: keeps waste out of landfills, cuts down on how much new raw material we dig up. That trims energy use during production. Traditional geos often get treated with harsh chemicals to repel water. Eco-friendly ones skip the toxic stuff entirely. Instead, their waterproofing comes from how the fibers are woven or stuck together. The fabric’s structure makes a barrier that stops water from soaking into the slope—but still lets extra moisture drain out. That’s a big deal. Trapped water is one of the main reasons slopes fail. Another key difference? Eco-friendly geos are non-toxic. They don’t leak harmful stuff into soil or water, so safe for fish, birds, the bugs that keep ecosystems healthy. Even when they hit the end of their life—usually 10 to 15 years, depending on weather—many can break down naturally or get recycled again. This loop (old geos reused or composted) means they barely leave any footprint. For slope projects that need to follow environmental rules, this makes eco-friendly geos an easy pick. They work well, make compliance a total breeze.

How Geotextile Waterproofing Protects Hydraulic Slopes

To see why geo waterproofing works so well for hydraulic slopes, just look at how it interacts with the slope itself. Here’s the thing: lay an eco-friendly geo on a hydraulic slope, and it’s kind of a two-in-one fix—simple, but effective. First, its waterproof layer stops water from soaking into the slope’s soil. That’s critical. When soil gets too wet, it gets heavy, can’t hold itself together. Over time, that leads to erosion—or even the slope collapsing. But the geo doesn’t just block water. It also lets extra moisture escape. The fabric’s got tiny holes, so water building up on top—rain or surface runoff, either way—drains slowly. Won’t pool up and put extra weight on the slope. That balance—blocking water but letting extra drain—is what makes geo waterproofing better than other options. Concrete blocks all water, so moisture gets trapped. Chemical waterproofing often cracks, doesn’t drain well. Eco-friendly geos also add a physical layer of protection. They shield the slope’s soil from the force of moving water. Over time, fast water can wear away the top layer of soil. But the geo takes that hit instead, keeping soil intact. Some geos even have a rough surface that helps native plants take root. As plants grow, their roots wrap through the geo and into soil. That makes an even stronger bond, stabilizes the slope more. It’s a mix of nature and tech—works better than either alone.

Sustainability Beyond the Waterproof Layer

Eco-friendly geos don’t just do well with waterproofing. Sustainability here isn’t just talk—it’s in every step of how they’re made and used. Let’s start with production. Making these geos uses up to 30% less energy than old-school waterproofing materials. Why? Recycled materials don’t need as much processing as new ones. For example, turning plastic bottles into polyester fibers uses way less energy than making polyester from crude oil. Then there’s installation. Eco-friendly geos are light, easy to handle. Concrete needs big trucks and cranes to move and place. Geos, though? A small crew can roll ’em out with basic tools. No heavy gear needed—trims fuel use and construction time. The area around the slope gets less disrupted, too. During use, they barely need any maintenance. Traditional methods like concrete need regular checks and patching to fix cracks. But eco-friendly geos hold up against UV, mold, rust. They don’t break down easily in bad weather. So crew guys don’t have to come back year after year patching cracks. When they finally need replacing, many eco-friendly geos can be composted or recycled. Some are made from plant-based fibers that break down naturally in soil—even add nutrients instead of leaving waste. Others can be melted down and turned into new geos, so the material stays in use. This level of sustainability isn’t just good for the environment. Saves money too. Less maintenance, faster installation, fewer replacements—all that means lower long-term costs for project managers.

Performance That Stands Up to Real-World Conditions

A lot of people think eco-friendly products are less durable than traditional ones. But eco-friendly geos—their waterproofing included—prove that wrong. These products are tested to handle some of the harshest conditions a hydraulic slope can face. For example, they hold up against UV. Other materials break down in the sun over time, but eco-friendly geos keep their strength. In sunny spots, a traditional geo might start fraying or lose its waterproofing after a few years. These don’t. They also resist chemicals in some soils—like acids or alkalis. Near factories, soil can be more corrosive. But eco-friendly geos don’t break down when they touch those substances. Even in cold climates, where freezes and thaws crack concrete and other hard materials, geos stay flexible. They stretch a little with temperature changes, so no cracks that let water seep in. Another test? How well they handle heavy water flow. Along fast-moving rivers, the water’s force can be intense. But eco-friendly geos stick to soil, strong enough not to tear or shift. In fact, many eco-friendly geos have tensile strength (the ability to resist stretching or breaking) that’s equal to or better than traditional ones. That means they can handle the same stress without hurting the environment. For project teams that need to be sure their slope protection will last, this reliability matters—and eco-friendly geo waterproofing delivers it.

The Future of Hydraulic Slope Protection

More countries and cities are setting goals for green infrastructure. And eco-friendly geos are on track to become the standard for hydraulic slope protection. Governments are adding more environmental rules to construction projects. Geo waterproofing checks all the boxes: non-toxic, uses recycled materials, cuts carbon emissions. This shift isn’t just about following rules. It’s about building infrastructure that lasts. Eco-friendly geos help make slopes that stay stable for decades. That means fewer emergency repairs—ones that cost a lot, cause disruptions. We’re also starting to see small tweaks in eco-friendly geo design. Some manufacturers add natural ingredients—like enzymes that help break down organic matter in soil—to help plants grow better. Others are making geos that change color when damaged. That makes inspections easier. These small fixes make geo waterproofing even more effective—easier to use too. Another trend? Using eco-friendly geos with other green technologies. For example, some projects pair geos with rain gardens or permeable pavement to manage water flow better. This whole-system approach to slope protection doesn’t just keep slopes stable. It helps recharge groundwater, supports local ecosystems. As more teams see the benefits—lower costs, less environmental harm, reliable performance—eco-friendly geos will become the go-to solution for hydraulic slopes everywhere.

Why This Matters for Our Communities

At the end of the day, protecting hydraulic slopes is about protecting the communities that depend on them. Stable riverbanks stop floods from destroying homes and businesses. Healthy reservoir slopes make sure there’s a steady supply of clean water for drinking and farming. Strong canal slopes keep irrigation systems working—so local farms can feed people. Eco-friendly geos and their waterproofing make all this possible without hurting the environment. They let us build infrastructure that serves people and the planet. No need to pick one over the other. Any town by a river might use eco-friendly geos to reinforce its riverbank. The geo keeps the bank from eroding, so the town doesn’t have to worry about floods. It also doesn’t contaminate the river, so local fishermen can still catch fish, kids can play in the water safely. The geo might even help native plants grow along the bank. That makes the area nicer—helps out birds and other wildlife too. These small, everyday benefits add up to a healthier, more sustainable community. That’s the real power of eco-friendly geos. They’re not just a construction product. They’re a way to build better places to live.

Wrapping Up

Eco-friendly geotextiles have changed the game for hydraulic slope protection. They fix the problems with traditional methods—pollution, lots of maintenance, short lifespans—and still deliver the performance engineering teams need. Their waterproofing keeps slopes stable. Their sustainable design keeps the environment safe. And their durability keeps costs low. As we keep focusing on green infrastructure, eco-friendly geos will only get more important. They’re a simple, no-fuss fix. They prove we don’t have to choose between building solid infrastructure and protecting the planet. For anyone on hydraulic slope projects—whether it’s a small community riverbank or a big reservoir—eco-friendly geos give you a way to get the job done right. Today, tomorrow, years to come. They’re not just protecting slopes. They’re protecting our future.