The Key Role of Geomembranes in Contaminated Site Remediation and Isolation Projects

Cities are growing fast, and old industries are changing. That leaves a lot of contaminated sites—closed factories, old garbage dumps, stuff like that. These places aren’t just bad for the land and water nearby. They also stop us from using the land again, and even risk people’s health. So cleaning these sites up has become a big deal for environmental work all over the world.

There are lots of ways to fix contaminated sites. But one method works well, stays reliable, and doesn’t cost too much: using geomembranes to lock in the pollution. And when you talk about this method, the hdpe geomembrane sheet is the most important part. Nothing else can do its job.

1. Why Contaminated Sites Need Fixing Fast, and What Isolation Technology Has to Do

Contaminated sites are like hidden risks in and around cities. The toxic stuff in them—heavy metals, volatile chemicals, things that don’t break down easily—doesn’t stay still. When it rains, the toxins soak into the ground. They seep deeper into the soil and groundwater, spreading out into big plumes that are hard to control.

Once these toxins get into the food chain—through drinking water or crops—they hurt people for a long time. Like, they might make cancer more likely. Or damage the nervous system, especially in kids.

The old ways of cleaning up, like digging up the contaminated soil, have problems. They’re slow. They need a ton of work. And half the time, they end up causing more pollution while you’re digging. That’s where isolation technology comes in. It has two main jobs: keep the existing pollution from spreading to clean areas, and stop rain or other outside stuff from making the pollution worse.

Clay layers used to be what people used for isolation. But clay isn’t reliable. It lets water through easily. It’s not stable. And over time, when the weather or ground changes, it cracks. That’s why geomembranes are better now. And the hdpe geomembrane sheet is the best of these. It’s like a solid barrier that locks pollution in. It fixes all the problems clay can’t.

2. What Makes Geomembranes Good for Isolation—And Why HDPE Sheets Are the First Pick

Geomembranes are thin sheets made from polymers. They don’t let water through. Their main job in cleaning up sites is to make a continuous layer that blocks pollution from moving. They’re good at keeping water out. They’re strong when you pull them. And they can handle chemicals—all things you need for this work.

But not all geomembranes are the same. Engineers and environmental teams almost always pick hdpe geomembrane sheets first. Here’s why:

First, hdpe geomembrane sheets barely let any water through. HDPE (that’s High-Density Polyethylene) has a tight molecular structure. So the sheets made from it have a water permeability coefficient usually below 1×10^-12 cm/s. To compare, clay’s is between 1×10^-7 and 1×10^-5 cm/s. That’s a huge difference. So even if the groundwater level is high, or there’s a lot of pressure, the hdpe geomembrane sheet keeps pollution from seeping out. It locks it safely in the isolated area.

Second, these sheets hold up against chemicals. Contaminated sites have lots of corrosive stuff that breaks down other materials over time. But hdpe geomembrane sheets can handle most acids, alkalis, salts, and solvents. Tests show that even after soaking in harsh solutions for a year, their strength and flexibility only drop by less than 5%. Other geomembranes? They can lose over 20% of their performance in the same time. So these HDPE sheets stay useful for years, even in tough site conditions.

They’re also strong and flexible. When you’re cleaning up a site, geomembranes can get hit by machines, trucks, or the pressure from soil. If they’re not strong enough, they tear or get punctured. Then the whole isolation system fails. But hdpe geomembrane sheets have a tensile strength over 20 MPa. They can stretch more than 600% before breaking. So they handle pressure and movement without getting damaged. And they’re flexible enough to fit over bumpy ground. That way, there are no gaps between the sheet and the soil.

Finally, they last a long time and are good for the environment. hdpe geomembrane sheets can stay in good shape for over 50 years. Most sites need to stay isolated for 30 to 50 years—so that matches. They’re also non-toxic. No harmful stuff leaks into the soil or water. And when the project’s done, you can recycle them. That fits with green, sustainable environmental work.

3. How HDPE Geomembrane Sheets Work in Real Cleanup Projects

hdpe geomembrane sheets don’t just sound good on paper. They’ve proven themselves in real cleanup projects all over the world. They deliver results when it counts.

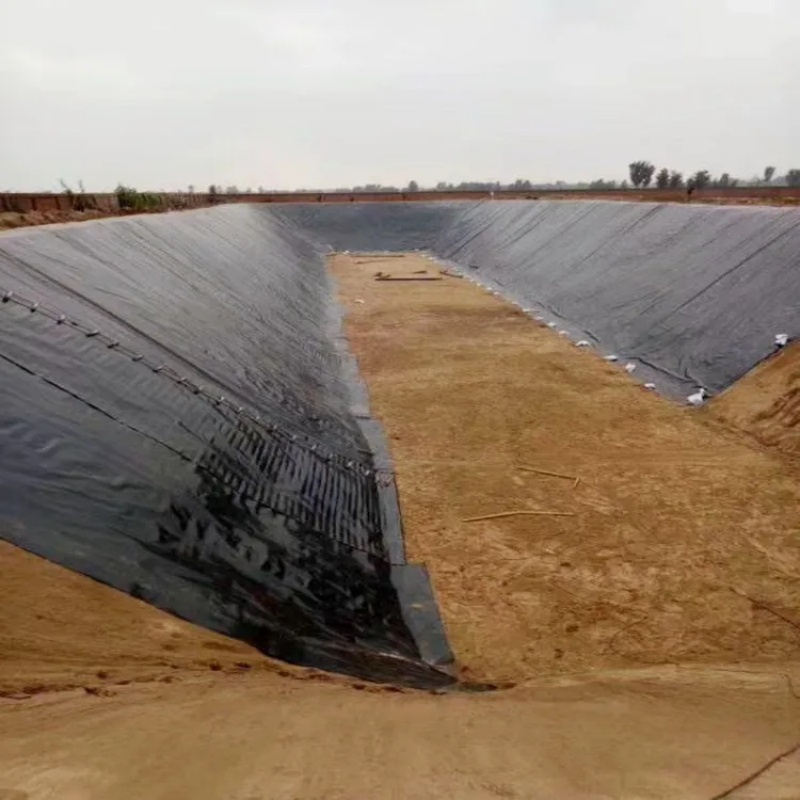

Take one old landfill. It had been used for decades. It needed cleaning because the leachate—toxic liquid from the waste—had seeped into the nearby soil and groundwater. It even polluted a river close by. The team decided to use isolation plus collecting the leachate.

First, they cleared the top of the landfill. Then they flattened and pressed down the ground. After that, they laid 2.0mm thick hdpe geomembrane sheets over the landfill and its slopes. They welded the sheets together with hot-melt methods to make sure there were no seams or leaks. They also added pipes under the sheets to collect the leachate and send it to a treatment station.

Five years later, tests showed the groundwater pollutants were back to safe levels. The river’s water quality was normal too. They even turned the landfill into a city park. That wouldn’t have happened without the hdpe geomembrane sheet’s reliable impermeability keeping the leachate in check.

Another project was a closed smelter. The soil there was really polluted with lead and zinc. The plan was to dig up the most contaminated soil. For the rest, they used in-situ isolation. For that lighter pollution area, they laid 1.5mm hdpe geomembrane sheets on the ground. Then they added a layer of clean soil and planted vegetation on top.

The sheets stopped the heavy metals from seeping deeper. The clean soil and plants kept people from touching the polluted ground. And they made the site’s ecology better. Within a few years, pollutant levels were below standards. The area had a healthy ecosystem with plants growing well.

These projects show that hdpe geomembrane sheets don’t just lock in pollution. They work with other cleanup methods to make sites safe and usable again.

4. Key Things to Get Right When Choosing and Using HDPE Geomembrane Sheets

Even the best hdpe geomembrane sheets won’t work if you don’t pick the right ones or install them properly. Every step matters—from choosing to building to maintaining. Mess up one step, and the isolation system fails. Then the whole cleanup effort is ruined.

When choosing hdpe geomembrane sheets, start with thickness. How thick you need depends on three things: how polluted the site is, what kind of toxins are there, and the ground conditions. If the site is heavily polluted, or the groundwater pressure is high, go with thicker sheets—2.0mm to 2.5mm. That keeps them strong and leak-proof. If the pollution is light and the ground is stable, thinner sheets (1.0mm to 1.5mm) work. And they save money.

Also, always buy from good manufacturers. Ones that have full quality reports and certifications. Cheap sheets from small workshops are bad news. They often have uneven thickness. They’re hard to weld. Or they’re not strong enough. That leads to leaks later on.

Installation is just as important. First, get the base layer ready. It needs to be flat. It needs to be pressed down tight. And it can’t have sharp things—like stones or metal. Sharp objects can puncture the hdpe geomembrane sheet. So either remove them, or cover the area with geotextile to protect the sheet.

When laying the sheets, follow the “bottom to top, low to high” rule. That stops water from getting trapped under the sheet. Lay them flat—no tight spots or wrinkles. And make sure adjacent sheets overlap 10 to 15cm.

Welding is the most important step for keeping leaks out. Use hot-melt welding. Adjust the temperature, speed, and pressure based on how thick the sheet is and the weather. After welding, test the seams. Use air or water pressure. If there’s a leak, fix it right away. Keep testing until it passes.

Once installed, check the sheets carefully. Look for cracks, punctures, or wrinkles. Use a leak detector on the whole layer. During the project’s operation, check the hdpe geomembrane sheet regularly. If there’s damage—from animals, people, or natural disasters—fix it right away. Also, don’t put heavy things on the sheets. They’ll crush them.

5. What’s Next for HDPE Geomembrane Sheets in Site Cleanup

Environmental standards are getting stricter. Cleanup technology is getting better. So hdpe geomembrane sheets will be used more and more in site remediation. Their future will focus on three main areas.

First, better performance. Polymer technology is advancing. Researchers are modifying HDPE to make hdpe geomembrane sheets work even better. Like, adding nano-fillers or reinforcing fibers. That can make them more impermeable. More resistant to chemicals. And stronger. Some modified sheets already have a water permeability coefficient below 1×10^-13 cm/s. Those are perfect for the most heavily polluted sites.

Second, more uses. Right now, hdpe geomembrane sheets are mostly used for sites on land. But soon, they’ll be used in other places too. Like underwater sites—lake bottoms or riverbeds. And sites with radioactive pollution. For underwater work, they can be paired with floating structures to make a floating isolation layer. For radioactive sites, they’ll make radiation-resistant hdpe geomembrane sheets to lock in toxic substances. That protects the area around them.

Third, smarter and faster construction. Right now, laying and welding these sheets is mostly done by hand. It’s slow. And it takes a lot of work. But soon, things will change. Unmanned laying machines and automatic welding robots will take over. That makes construction faster. And the quality will be more consistent.

BIM (Building Information Modeling) technology will help too. It can track the sheets from when they’re made, through transportation and construction, to maintenance later. That way, every step is monitored and managed. So the sheets work as well as possible.

Conclusion

Using geomembranes for isolation is a key way to control pollution and protect the environment when cleaning up sites. And the hdpe geomembrane sheet is the core of this method. It can block water. It resists chemicals. It’s strong. And it lasts a long time. That’s why it’s the top choice for projects all over the world.

Real projects prove it solves the biggest isolation problems. It helps reuse land. And it improves ecosystems.

As material and construction technology get better, hdpe geomembrane sheets will work even better. And they’ll be used in more places. They’re a critical part of environmental work. They help make cities greener and safer for people.

That’s why, when cleaning up contaminated sites, you have to focus on the key role of hdpe geomembrane sheets. Pick the right ones. Install them properly. Keep them well-maintained. That way, environmental protection work is effective—and it lasts.