The Implementation Principle and Design Parameters of Geotextile Sheet's Filtration Function in Water Conservancy Projects

In water conservancy projects, there’s one big problem you can’t ignore: keeping water flowing smoothly while stopping soil from washing away. Lately, a material called geotextile sheet has become really key for fixing this. It’s great at filtering, but a lot of people don’t get how it actually does its job. They also don’t know what things matter when you’re planning to use it. This article will break down how geotextile sheet’s filtration works in water conservancy projects. It’ll also go over the key things to think about when designing its use. I’ll keep it simple—so anyone in the industry or related fields can easily follow along.

1. The Basic Concept of Geotextile Sheet in Water Conservancy Filtration

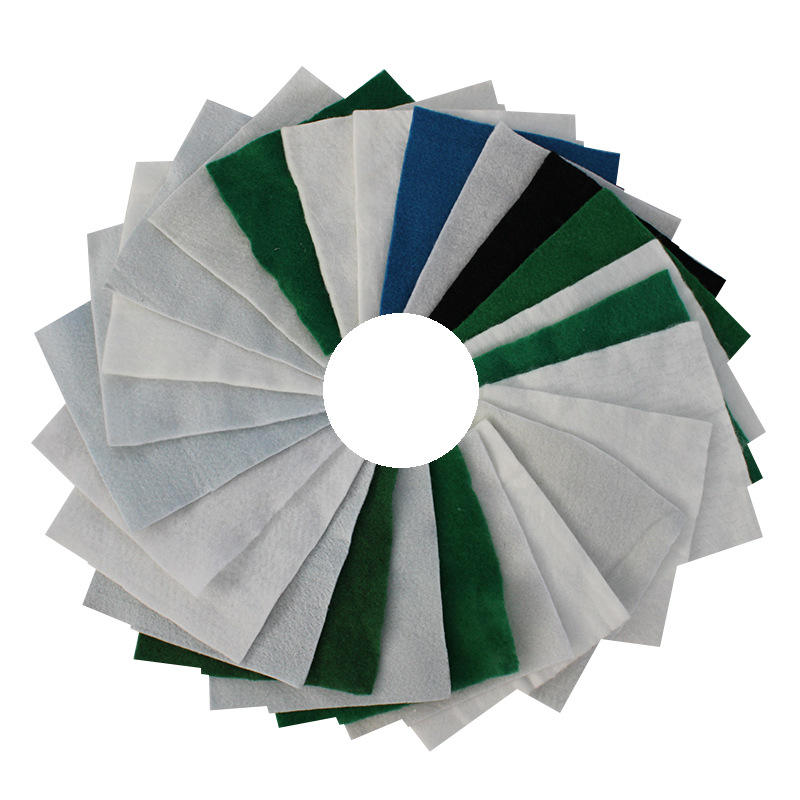

Before we talk about how it works and what design factors matter, let’s first make clear what geotextile sheet is, especially when it comes to filtering in water conservancy. A geotextile sheet is a permeable fabric. It’s made from synthetic fibers—things like polyester or polypropylene. It’s not like regular cloth, though. This one’s built to handle the tough conditions in water conservancy projects. That means it can stand being in water for a long time. It can deal with chemicals in the soil, too. And it can take mechanical stress without breaking. When you use it for filtration, geotextile sheet acts like a barrier. Water can go through, but soil particles can’t. This stops soil erosion—and that’s a big deal. Without it, erosion would damage things like canals, dams, and drainage systems. It also keeps the water in these systems clear, so it flows well. If you didn’t have geotextile sheet, a lot of water conservancy projects would have constant issues. Channels would get clogged up. Water wouldn’t flow as it should. In some cases, the whole structure might even fail—just because too much soil washes away.

2. The Implementation Principle of Geotextile Sheet's Filtration Function

Geotextile sheet doesn’t just filter like a simple sieve in water conservancy projects. There are a few different ways it works, and they all come together to let water through while holding onto soil. If you understand these ways, you’ll see why geotextile sheet is so useful here.

First off, there’s mechanical interception—this is the most basic way it works. Geotextile sheet has a network of small holes. When water with soil particles flows through it, the bigger soil particles get blocked by these holes. It’s a bit like using a sieve to separate big and small particles. But the holes in geotextile sheet aren’t random. They’re made a specific size. That size is picked to target the soil particles that would cause the most trouble in the project.

Second, adsorption and retention helps catch the smaller soil particles. Even if some tiny soil particles are small enough to get through the initial holes of the geotextile sheet, they don’t just pass right through. They can stick to the surface of the fiber network. The synthetic fibers have a small electric charge on their surface. That charge pulls in those small particles and holds them there. Over time, a thin layer of soil builds up on the geotextile sheet. People call this layer a “filter cake.” This layer acts like an extra filter. It catches even smaller particles that the original holes might have let through. But you have to watch out for one thing—if this layer gets too thick, it will slow down how much water can pass through the geotextile sheet. The good news is, the way geotextile sheet is made keeps this layer thin enough to work well.

Third, hydraulic gradient adjustment helps keep water flowing steadily. In water conservancy projects, when water flows, it creates something called a “hydraulic gradient.” That’s just the difference in water level over a certain distance. If this gradient is too high, the water moves too fast. And fast water is a problem. It can wash away soil particles. It might even damage the geotextile sheet. Geotextile sheet helps fix this by controlling how fast water flows. Its permeable structure lets water go through at a steady rate. That brings the hydraulic gradient down to a safe level. This does two things: it keeps the soil from washing away, and it makes sure the project runs well. The water flows consistently, just like it needs to.

Through all these ways, geotextile sheet is the main part of the filtration process. Its structure, the material it’s made from, and the size of its holes—all of these are optimized to support these filtration methods. That’s why it’s a reliable choice, no matter how big or small the water conservancy project is.

3. Key Design Parameters of Geotextile Sheet for Water Conservancy Filtration

Picking the right design details is super important when you’re using geotextile sheet for filtration in water conservancy. These details decide two big things: whether the geotextile sheet will work well, and how long it will last in the project’s specific conditions. Below are the main things engineers and project managers need to think about.

3.1 Pore Size (Equivalent Opening Size, EOS)

The size of the holes in geotextile sheet—people usually call this Equivalent Opening Size (EOS)—is one of the most critical design points. It directly affects two things: can the geotextile sheet block soil particles, and can it still let water through? EOS is usually measured with tests. Things like dry sieving or wet sieving. When you’re choosing EOS for a project, you have to look at the soil in the area where the project is happening. Specifically, the size of the soil particles there. If the EOS is too big, soil particles will just go through the geotextile sheet. That leads to two problems: soil erosion and clogs in the project’s channels. If the EOS is too small, though, water can’t flow well. The whole system ends up working less efficiently. So before you decide on EOS for the geotextile sheet, you need to test the soil carefully. You have to know how big the particles are.

3.2 Permeability Coefficient

Permeability coefficient is just a way to measure how well geotextile sheet lets water through. To be specific, it’s calculated as how fast water flows through the geotextile sheet when there’s a certain hydraulic gradient. In filtration, the permeability coefficient of the geotextile sheet has to match the permeability of the soil around it. More precisely, the geotextile sheet’s coefficient should be at least 10 times higher than the soil’s. This is important because it makes sure water can flow through the geotextile sheet easily. If it’s not, water builds up behind the geotextile sheet. That build-up creates pressure. And that extra pressure is bad—it can make the soil unstable. It might even damage the geotextile sheet. So how do you find the right coefficient? Engineers first test how permeable the local soil is. Then they pick a geotextile sheet that has a coefficient 10 times higher than that.

3.3 Tensile Strength and Elongation

Water conservancy projects deal with a lot of mechanical stress. There’s the weight of the soil pressing down. There’s pressure from the water, too. And sometimes, there’s force from construction work. So geotextile sheet needs to be strong enough to handle all this stress. It can’t break, and it can’t stretch out of shape. Tensile strength is how much force the geotextile sheet can take before it breaks. Elongation is how much it stretches (measured as a percentage) before it breaks. The amount of strength and stretch needed depends on the project. If the geotextile sheet isn’t strong enough, it will tear under stress. And if it tears, it can’t filter anymore. Then soil starts eroding. If it stretches too much, that’s a problem too. The size of its holes changes, and that messes up its filtration. So when you’re choosing geotextile sheet, engineers first figure out how much stress the project will put on it. Then they pick one with enough strength and stretch to handle that stress. That way, it lasts a long time.

3.4 Chemical Resistance

In water conservancy projects, geotextile sheet comes into contact with a few things: water, soil, and sometimes chemicals. Those chemicals can be different. In projects for farming water use, they might be fertilizers or pesticides. In some city water projects, they could be industrial wastewater. So geotextile sheet needs to resist these chemicals. If it doesn’t, it will break down or get damaged. How well it resists chemicals depends on the type of synthetic fiber used. For example, polyester geotextile sheets are really good at handling acids and alkalis. So they’re a good choice for projects where the soil or water has a high pH level. Polypropylene ones are better at handling organic solvents. So before you pick a geotextile sheet, you need to test the soil and water. You have to see what chemicals are in them. That way, engineers can choose one made from a fiber that can handle those specific chemicals. This makes sure the geotextile sheet keeps filtering well, and it stays strong over time.

3.5 Durability (Aging Resistance)

Water conservancy projects are built to last—usually for decades. So the geotextile sheet used here needs to be durable. And one of the most important parts of durability is resisting aging. Geotextile sheet ages for a few reasons. There’s sunlight’s UV rays, for one—those are really tough on it. There are changes in temperature, too. And sometimes, small organisms grow on it, which can cause damage. UV rays are one of the biggest problems. They can break down the chemical bonds in the synthetic fibers. When that happens, the geotextile sheet gets weaker. It also becomes less able to let water through. To fix this, manufacturers often add “UV stabilizers” to the fibers when they make the geotextile sheet. The thickness matters too—thicker geotextile sheets usually last longer. They can handle more wear and tear. So when you’re planning to use geotextile sheet, engineers first think about how long the project needs to last. Then they pick one that can resist aging enough to last that long.

4. Practical Application Examples of Geotextile Sheet in Water Conservancy Filtration

To get a better idea of how geotextile sheet’s filtration works—and what design details matter in real projects—let’s look at two simple examples.

4.1 Canal Lining Filtration

In a lot of farming areas, canals are used to carry water for irrigation. But the soil along the canal banks is often loose. When water flows through the canal, it washes away that loose soil. Over time, the canal gets narrower. And when it gets narrower, less water can flow through. That’s where geotextile sheets come in—they fix this when used in lining the canal. Here’s how it works: first, you test the soil to see how big the particles are. Then you pick a geotextile sheet with the right EOS to block those particles. You also make sure its permeability coefficient is 10 times higher than the soil’s. Plus, you choose one with enough tensile strength and elongation to handle the stress from the soil and water. It also gets treated with UV stabilizers to resist sunlight. Once it’s installed, the geotextile sheet does its job. It blocks the soil particles, so no erosion happens. Water flows through easily. And the canal works well for years—no soil builds up to clog it.

4.2 Dam Drainage Filtration

Dams are important structures—they store water and control how it flows. But there’s one big issue with dams: drainage. If too much water builds up inside the dam, it puts more pressure on the structure. And that extra pressure can make the dam fail. Geotextile sheets are used in the dam’s drainage system to fix this. They filter the water and keep soil from clogging the drainage pipes. Here’s the process: you pick a geotextile sheet with EOS that blocks the sand particles in the dam’s soil. Its permeability coefficient is set higher than the dam’s soil—so water can drain fast. It also has enough tensile strength to handle the weight of the soil and water on top. The geotextile sheet is wrapped around the drainage pipes, making a filter layer. When water seeps through the dam’s soil, it goes through the geotextile sheet first. The sheet blocks the sand, so the pipes don’t get clogged. This keeps the drainage system working. It lowers the water pressure inside the dam. And that makes the dam more stable.

5. Conclusion

Geotextile sheet is essential for filtration in water conservancy projects. It filters by using three methods—mechanical interception, adsorption and retention, and hydraulic gradient adjustment. All three work together to let water through and hold onto soil. When you’re planning to use geotextile sheet, you have to carefully consider five key things: pore size, permeability coefficient, tensile strength, chemical resistance, and durability. These things directly affect two big outcomes: how well the geotextile sheet works, and how long it lasts. If you pick the right geotextile sheet—with the correct design details—water conservancy projects won’t have big problems. Things like soil erosion, clogged channels, or structural failure won’t happen. The projects will run efficiently for a long time. As water conservancy keeps developing, geotextile sheet will be used more and more. And as more research is done, and new ideas come up for its design and performance, it will keep making water conservancy projects more efficient and sustainable all over the world.