HDPE Geomembrane Liner UV Aging Protection: Practical Tips for Outdoor Use

If you’ve ever worked on outdoor projects where you need to keep water in or out—like ponds, tanks, or even just covering a site—chances are you’ve used a hdpe geomembrane liner. It’s one of those go-to materials because it stops leaks pretty well, but here’s the catch when you use it outside: the sun. UV rays from sunlight don’t just fade your garden chairs or give you a sunburn; they slowly break down HDPE over time. After a few years, the liner gets brittle, starts cracking, and stops doing what it’s supposed to. That’s not just a pain—it can mean shelling out extra cash for fixes later, or even messing up the area around your project if leaks start. But here’s the good news: you don’t have to just live with this. There are simple steps to protect your hdpe geomembrane liner from UV damage, and I want to walk you through them. These aren’t some fancy, hard-to-do tricks—just stuff that actually works when you’re out there dealing with real outdoor projects day after day.

1. Pick the Right HDPE Geomembrane Liner to Start With

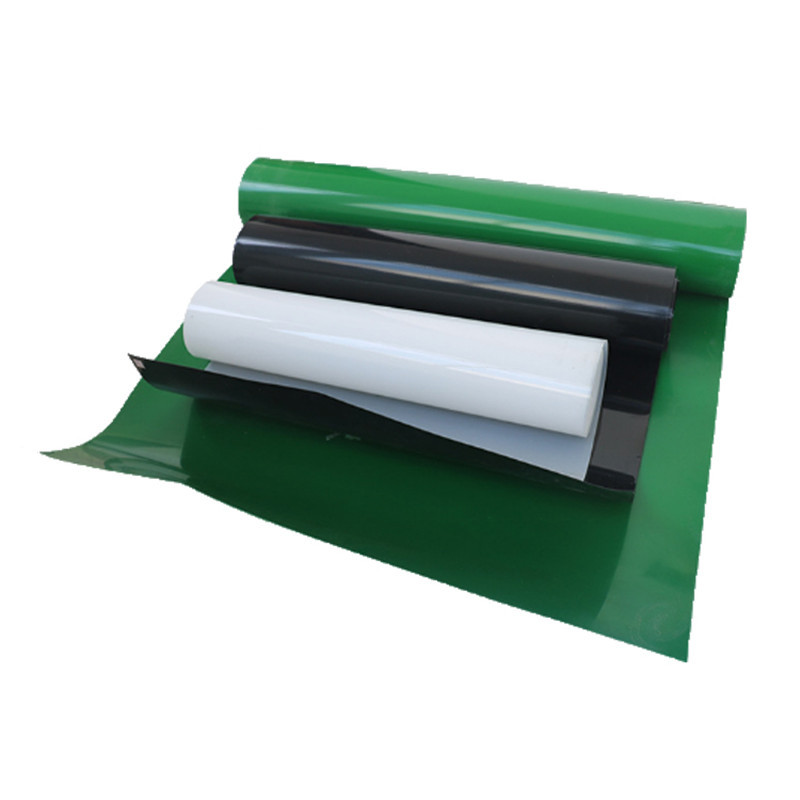

Not all hdpe geomembrane liner options are the same, especially when it comes to handling the sun. A lot of people make the mistake of grabbing the cheapest HDPE liner they can find, thinking “oh, it’ll work fine outside.” But regular HDPE without any extra protection might hold up if it’s covered or used indoors, but outside? It starts looking beat up pretty quick. You need a hdpe geomembrane liner that’s made specifically to stand up to UV rays.

These UV-resistant liners have special additives mixed in when they’re manufactured. The most common one is carbon black—it soaks up UV rays before they can get into the material and break it down. But you don’t want too much or too little of this stuff. Usually, 2% to 3% carbon black is about right—enough to protect against the sun without making the liner so stiff you can’t work with it. If there’s not enough, the protection won’t last long. If there’s too much, you’ll struggle to lay it down, especially if the ground isn’t perfectly flat.

Another thing to check is what the manufacturer says about UV resistance. Good brands will have done tests to show how their hdpe geomembrane liner holds up when it’s in the sun a lot. They’ll simulate years of sunlight in a lab and tell you roughly how long the liner should last outside. Try to get one that’s rated to handle UV for at least 15 to 20 years. That way, you won’t have to replace the liner sooner than you need to, which saves you time and money down the line.

2. Add a Protective Layer Over the HDPE Geomembrane Liner

Even if you’ve got a uv-resistant hdpe geomembrane liner, throwing another layer on top is a smart move—trust me, I’ve seen projects where skipping this step leads to early damage. Think of it like wearing a hat on a super sunny day: your sunscreen (that’s the liner’s UV additives) is still doing its job, but the hat takes the first hit from the sun. That way, the liner itself doesn’t have to deal with as much UV exposure.

What kind of layer should you use? Well, geotextiles are probably what you’ll see most often. They’re thin, fabric-like sheets you just lay right on top of the hdpe geomembrane liner. The best part? You don’t need any fancy tools to put them down—just unroll and smooth them out. They don’t just block UV, either; they also keep the liner safe from scratches. I’ve had projects where rocks or even people walking on the liner would’ve torn it if there wasn’t a geotextile over it. Just make sure you get the non-woven kind—they’re denser, like felt, so they block more sun than the woven ones. And hey, check if it works with your hdpe geomembrane liner first. Some cheap geotextiles can react with HDPE after a while, which is the last thing you want.

If you care about how the area looks, or if you need something that lets water drain, gravel or dirt works too. A thin layer—maybe 3 to 5 inches—of clean, packed gravel keeps the sun off and lets water run away, so it doesn’t sit on the liner. Dirt is good if you want it to look natural, but watch out for sharp bits in it—they can poke holes in the hdpe geomembrane liner. If you use dirt, put a thin geotextile between the dirt and the liner. HDPE doesn’t let much through, but the geotextile keeps dirt from clogging tiny spots, which helps everything last longer.

The biggest mistake here is trying to save money on the protective layer. A flimsy geotextile that rips easily, or gravel that’s too thin, won’t do anything to protect the hdpe geomembrane liner. Spend a little extra on something sturdy now, and you won’t have to replace the liner early. It’s worth it.

3. Install the HDPE Geomembrane Liner the Right Way

I’ve seen so many good hdpe geomembrane liner projects fail just because they weren’t installed right. Even the best UV-resistant liner won’t last if you mess up the installation—bad installs create weak spots where UV can get in, or where water sits and makes damage worse. So getting this step right is just as important as picking the right liner. Let me break down what you need to do.

First, get the ground ready. The area where you lay the hdpe geomembrane liner needs to be smooth and flat. No sharp rocks, roots, or trash—anything that could poke the liner or stretch it out. If the ground is bumpy, the liner will stretch in some spots, and those stretched parts are thinner. Thinner parts get damaged by UV way faster. Use a roller to pack the ground down, and fill in any holes or bumps with sand or fine gravel. This doesn’t just keep the liner from tearing; it also makes sure it lies flat. When it’s flat, UV hits it evenly—no thin spots to worry about.

Next, take it easy when unrolling and securing the liner. When you’re laying out the hdpe geomembrane liner, don’t pull it too tight. HDPE shrinks a little over time, and if it’s too tight, it’ll crack when it gets smaller. Leave a little slack—maybe 1% to 2% of the liner’s length. That way, it can move when the temperature changes without breaking. When you secure it, use anchor trenches or weights (like concrete blocks) along the edges. And make sure the edges are fully covered by the protective layer—geotextile, gravel, whatever you’re using. The edges are usually the first to break down because they’re more likely to be exposed if the protective layer shifts.

Welding the seams is another big one. The spots where two pieces of hdpe geomembrane liner meet are weak if the weld isn’t done right—UV loves to attack those spots. For outdoor projects, use a double-track heat welder. It makes two welds side by side, which is way stronger than a single weld and less likely to crack. After welding, test the seams with an air pressure test. Here’s how that works: pump air into the seam until it’s at 0.2 MPa, then wait 5 minutes. If the pressure doesn’t drop, it’s sealed right. A good seal doesn’t just stop leaks; it also keeps water from getting trapped between the liner and the ground. Trapped water gets warm and damp, which makes UV damage worse—mold grows, and the material breaks down faster.

4. Check on the HDPE Geomembrane Liner Regularly

Once the hdpe geomembrane liner is installed, you can’t just forget about it. Outdoor conditions are all over the place—wind can blow the protective layer away, heavy rain can wash gravel off, and animals or trash can scratch the liner. A little regular checking can catch these problems early, before they turn into big UV damage issues.

Set up a schedule to look at the liner once a month. Do it more often in summer, when the sun is strongest. When you check, focus on three things: the protective layer, the liner itself, and the seams. First, see if the geotextile or gravel has moved. If any part of the hdpe geomembrane liner is exposed, cover it back up right away. Then, look at the liner’s surface. Are there any signs it’s getting old? Like fading from black to gray, small cracks, or parts that feel brittle when you touch them. If you see any of these, mark the spot and plan to fix it soon. Small issues get worse fast when the sun’s hitting them every day.

Check the seams too. Are there any gaps or places where the weld is coming apart? If you find a small gap, clean the area well and use a HDPE patch to seal it. Make sure the patch is at least 10 cm bigger than the gap on all sides, and weld it properly so it doesn’t leak later. For bigger problems—like a torn section of liner—it’s better to call someone who installs these liners for a living. They have the right tools and know-how to replace the damaged part without messing up the rest of the hdpe geomembrane liner.

Oh, and here’s a quick maintenance tip I always tell people: wipe down the liner’s surface every so often, especially if it’s covered in dirt or algae. Dirt doesn’t hurt the liner directly, but it can trap moisture and heat. That extra warmth makes UV damage happen quicker, and you don’t want that. Just use a soft brush and some mild soap—nothing harsh, because strong chemicals can mess up the HDPE. It’s a 5-minute job, but it really helps the liner last longer.

5. Know When to Replace the HDPE Geomembrane Liner

Let’s be real—no matter how well you look after it, every hdpe geomembrane liner will eventually wear out from sitting in the sun. The key is knowing when to swap it out, because waiting too long can cause big problems. If you let it go too far, you’ll end up with leaks, and those can ruin the area around your project. Plus, fixing leaks usually costs more than just getting a new liner in the first place.

So how do you tell when it’s time for a new liner? There are a few clear signs. If you see cracks all over, or if the liner breaks easily when you press on it, that means UV damage is too bad to fix. Another sign is if it’s not stopping leaks like it used to. If you notice water seeping through, even after you’ve fixed small cracks, the liner’s structure is probably shot. You can also check the thickness with a caliper. If it’s 10% thinner than when you installed it, it’s not protecting against UV or damage like it should.

When you replace the hdpe geomembrane liner, take the chance to get a newer, more UV-resistant model. Manufacturers are always making these products better, so the new one will probably last longer and protect better than the old one. Just make sure you follow the same installation and maintenance steps you did before. Even the best new liner won’t last if you install it poorly—so don’t skip those steps.

Final Thoughts

Here’s the thing about protecting a hdpe geomembrane liner from UV damage outside: it’s not hard, it just takes a little time to pay attention. You don’t need to be an expert—just do four simple things. First, get a liner that’s made to handle the sun. Then, add a protective layer on top. Install it the right way, not in a rush. And check on it every once in a while. Do those things, and you can make the liner last 20 years or more.

Why does this matter? Because the hdpe geomembrane liner is what keeps your outdoor project from leaking. If it fails, you’re looking at extra work and extra money to fix it. Whether you’re working on a small garden pond or a big industrial site, these steps work. I’ve used them on projects of all sizes, and they always make a difference.

At the end of the day, this is just about making your life easier. You don’t want to be halfway through a project, or a few years later, having to tear everything up because the liner got ruined by the sun. A little bit of effort now saves you a lot of hassle later. So take the time to protect your hdpe geomembrane liner—you’ll be glad you did.