Geotextile "slimming" successful: lightweight while maintaining high strength

Geotextile "Slims Down" Successfully: Lightweight Yet Maintains High Strength

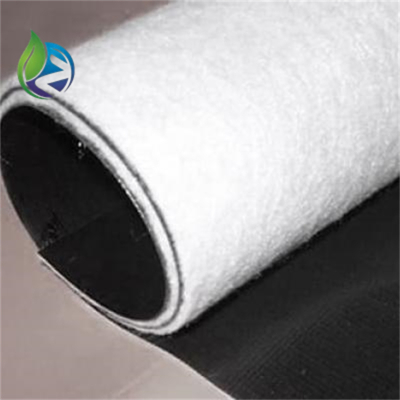

In infrastructure and construction, let’s be honest—geotextiles have been quiet workhorses for ages. They reinforce soil, stop erosion, and shield structures from water damage. Jobs that keep roads from giving out mid-drive, dams holding steady through storms, and landfills intact for years—nothing flashy, just straight-up essential. But for decades, one problem just wouldn’t budge: traditional geotextiles are bulky. Like, really bulky—rolls that feel like lifting a cinder block when you grab the end. Hauling them to remote job sites? Jacks up fuel costs something fierce, especially when you’re crawling down dirt roads that guzzle gas. Moving them around during installation? Slows crews down so much, you’d swear the material was actively fighting you. Now, though—new innovation’s shaking things up. Manufacturers have actually “slimmed down” geotextiles—cranking out lighter versions that still pack the high strength and durability the industry counts on. This isn’t some tiny upgrade. It’s a real fix for the logistical headaches construction teams deal with daily—and geotextile waterproofing stays front and center the whole time, no shortcuts, no compromises.

The Drive for Lightweight Innovation in Geotextiles

Wanting lighter geotextiles isn’t some random brainstorm over coffee. Construction projects these days get more complex by the day—high-speed rail cutting through farmland, coastal protection in bays you can barely reach by truck, mountain road expansions with zero room for big rigs to turn around. Teams need materials easier to haul without losing an ounce of performance. Traditional geotextiles? Mostly thick layers of woven or non-woven fibers—nothing fancy, just plain bulky. They can weigh up to 500 grams per square meter. And if a project needs thousands of square meters? That weight piles up fast. Trucks end up making extra trips—more gas, more time, more money. Cranes need more power to lift the rolls, rental fees spiking right along with it. Workers? They waste hours unfolding and placing the stuff. Hauling those heavy rolls up a gravel slope (slippery after rain, no less) used to leave crews sore for days. Sometimes you’d need two people just to shift one across the muck.

This inefficiency got researchers thinking: Could they trim excess weight without weakening the geotextile? Turns out, yes—but it meant ditching how geotextiles were always made. Early tries to lighten them? Total flops. The material would tear mid-installation, or couldn’t handle soil pressure like it should—stretching out, bunching up, basically failing at its only job. But by focusing on fiber quality and how layers are stitched together, manufacturers found a sweet spot. Today’s lightweight geotextiles are 20-30% lighter—no joke, you feel it instantly when you hoist a roll onto your shoulder. Some options hit 150 grams per square meter. And the biggest win? This weight cut doesn’t mess with key functions like geotextile waterproofing. For projects where water seepage could ruin the whole structure—dam repairs, highway subgrades—that’s non-negotiable. You can’t trade protection for ease of use. The new geotextiles just give you both, no catch.

Material Breakthroughs Behind the "Slimming"

The geotextile “slimdown” didn’t happen by accident. It comes down to two big material shifts: better fiber tech and smarter coating methods. No fancy science jargon here—just simple, effective changes that make a huge difference on the job.

First, manufacturers aren’t just using basic polyester or polypropylene fibers anymore. They’re switching to high-tenacity (read: high-strength) fibers that are thinner but way stronger than the old stuff. These fibers are built to resist stretching and tearing—even when heavy soil presses down hard, or sharp rocks scrape against them like a knife. Take one strand of the new high-tenacity polyester. It can hold more weight than a thicker strand of traditional fibers. That means fewer strands to get the same strength. Less material, less weight—no loss in durability. Trust me, it’s not rocket science. Just smarter material choices that do more with less. Carrying a roll of this stuff feels like swapping a backpack full of textbooks for a messenger bag—night and day, no contest.

Second, the coatings for water resistance have gotten a major upgrade. Back in the day, waterproof coatings added tons of bulk. They had to be thick to keep moisture out, cracked if you folded the geotextile too much, and just made the whole roll heavier than it needed to be. Now, manufacturers use thin, flexible polymer coatings that stick tight to the fiber surface. These coatings are lighter, sure. But they also mold to the geotextile’s texture—no tiny gaps where water can slip through. This mix of thin, tough fibers and lightweight coatings is what makes modern geotextiles slimmer but still solid at geotextile waterproofing. Even on a rain-soaked construction site, ground a mud pit and water everywhere, the coating holds up. Keeps water from messing with the soil or the structure above. No fancy tricks, just good, reliable protection that doesn’t weigh a ton.

Rigorous Testing Proves Strength and Durability

Lightweight geotextiles aren’t just a nice idea on paper—labs really put these things through the wringer to make sure they handle the chaos of real job sites. These tests mimic the worst-case scenarios: heavy loads from 18-wheelers or concrete trucks, nonstop exposure to rain and groundwater, even extreme temps—freezing winters that crack materials, scorching summers that warp them until brittle. Labs don’t go easy on these geotextiles. They want to see if they’ll hold up when the going gets tough, not just in perfect conditions.

One key test checks “tensile strength”—how much force the geotextile can take before breaking. Results? Lightweight models have tensile strength right up there with traditional, heavier ones. Often 20-30 kilonewtons per meter, give or take. Enough to stand up to compacted soil or heavy construction equipment—no flinching, no tearing. Another critical test focuses on geotextile waterproofing. Researchers submerge samples in water for weeks on end, then measure how much moisture seeps through. Lightweight versions perform just as well as thicker ones. Water penetration rates hit 0.1 liters per square meter per day—way below industry requirements.

You don’t have to take lab results alone, though—field tests on actual job sites back this up. Last year, on a highway expansion project in the Midwest, crews swapped old heavy geotextiles for the slimmed-down versions to reinforce the road base. They said the rolls were easier to unload and lay down—cut installation time by 15% compared to the old stuff. After six months of heavy traffic, inspections showed no wear, no fraying, no water damage. A lot of that’s thanks to reliable geotextile waterproofing keeping the road base dry, even through spring rains. These real wins are why more contractors are ditching the old heavy geotextiles. It’s not just hype—they’re saving time, money, and back pain without sacrificing an ounce of quality.

Real-World Applications Benefit from Lightweight Design

The perks of lightweight geotextiles aren’t limited to one type of project. They’re making waves in infrastructure, water conservancy, and environmental protection—all across the board. Contractors are snapping them up because they’re easier to work with, and still get the job done right.

In road and railway construction, lighter geotextiles mean fewer truck deliveries. Last year, on a remote mountain road project, crews used them and cut transport time by half. No more waiting for extra trucks to navigate narrow, winding paths that barely fit one vehicle. For a 10-mile stretch of highway, you can easily cut transport trucks by two or three. That lowers fuel costs and cuts carbon emissions—win-win for the budget and the planet. Crews also love that lighter rolls are easier to carry by hand. Hauling those rolls up a muddy incline used to be a nightmare. Now one guy can handle it without breaking a sweat. They lay faster, too—helps keep projects on schedule (and avoids those costly delay fees). And since geotextile waterproofing is still top-notch, the road base stays dry. Prevents potholes and cracks from water sitting under the pavement—saves a ton on repairs down the line.

In water conservancy projects—reinforcing riverbanks, repairing dams—lightweight geotextiles really shine. Traditional heavy ones are a nightmare to install in wet, muddy areas. They sink into the muck, get caught on rocks, and slow everyone down to a crawl. Rushing to beat a storm only increases the risk of mistakes. Lighter versions lay smoother, even in tight spaces or uneven terrain. Their strong geotextile waterproofing makes sure water doesn’t seep through the riverbank. If it did, soil would erode over time, and the whole structure would weaken until it gives out. Recently, on a river restoration project in the Pacific Northwest, crews used lightweight geotextiles to line the riverbed. Workers said the material was way easier to handle in the water—unrolled by hand instead of hauling extra equipment that gets stuck in the current. After a year of heavy rains and record-high water levels, the riverbank looked just as solid as installation day—no erosion, no gaps, no issues.

Even in environmental projects—landfill liners, wetland restoration—lightweight geotextiles work like a charm. Landfills need them to stop toxic liquids (called leachate) from seeping into the ground and polluting groundwater. Lighter geotextiles are easier to install over large, bumpy landfill sites. No need for heavy machinery to smooth them out—saves time and avoids damaging the site. Their geotextile waterproofing keeps leachate contained, so it doesn’t harm the surrounding area or seep into wells. In wetland restoration, the slim design lets the geotextile blend with natural surroundings. Protects young plants from erosion but still lets water flow through—super important for keeping wetlands healthy and supporting birds, fish, and other wildlife that depend on them.

Future Trends: Combining Lightness with Sustainability

The success of lightweight geotextiles is just the starting line. Manufacturers are now pairing this slim design with more sustainable features. The construction industry is going greener each year, and geotextiles are keeping up—no lagging behind.

One big trend? Using recycled materials for those high-tenacity fibers. Manufacturers are turning plastic bottles, old industrial fabrics, even discarded fishing nets into new geotextiles. This not only cuts down on landfill waste but keeps the material light—recycled fibers can be processed thinner than virgin ones without losing strength. Some manufacturers are even testing plant-based fibers for extra sustainability points. It’s a smart way to make a good product better, and it resonates with contractors wanting to reduce their environmental footprint (and impress clients who care about green building).

Another trend: adding “smart” features to lightweight geotextiles. Some models now have tiny sensors that track moisture levels or how much strain the material takes. These sensors are lightweight—no extra bulk, no performance issues. They send real-time data to a phone or tablet, so crews can check the geotextile’s condition without trudging across the entire site. Catches issues early—like a small tear in the geotextile waterproofing or a spot under too much pressure—before they become big, expensive problems. No more waiting for a leak to show up; fix it right away, save time and money.

As these innovations keep rolling, the future of geotextiles looks lighter and more capable by the day. The “slimdown” proved construction materials don’t need to be heavy to be strong. You can have something easy to work with that still stands up to tough conditions—no trade-offs. And with geotextile waterproofing staying a top priority, these new geotextiles are set to become a staple in projects worldwide. They’re not just a trend—they’re here to stay. Making construction more efficient, more sustainable, more reliable—no fancy jargon, no over-the-top claims, just results that matter for the people building our roads, dams, and protected spaces.