Geomembrane anti-seepage, the safety shield of engineering projects

Geomembrane Anti-Seepage: The Safety Shield for Engineering Projects

Modern engineering work—stuff like water conservancy projects, environmental protection facilities, or infrastructure such as roads and bridges—relies way more on anti-seepage than most people realize. It’s not just a “nice-to-have” step; it’s a critical part that directly impacts how safe a project is, how long it lasts, and how well it runs day in and day out. Water leaks? They’re no small problem. It doesn’t just wear down structures over time—it wastes valuable resources, messes up nearby soil and water, and can even hide risks that put lives and property in danger. That’s why geomembrane has become such a game-changer. As a high-performance anti-seepage material, it’s like a “safety shield” for all kinds of projects, thanks to its reliable leak-proofing and steady performance. Among all the geomembrane options out there now, hdpe black smooth geomembrane stands out for being solid all-around—tough, flexible, and you can count on it. No wonder so many engineering teams grab it first when anti-seepage is needed.

The Core Demand for Anti-Seepage in Modern Engineering

Engineering tech keeps moving forward, and quality and environmental standards are right along with it. That means the need for good anti-seepage tech and materials isn’t just growing—it’s getting more specific. Take water conservancy projects, for example. Reservoirs, canals, ponds—they all need solid anti-seepage. Without it, water seeps into the ground, wastes supply, and weakens the surrounding soil. We’ve seen projects drag on for months fixing that kind of damage. For environmental projects—landfills, sewage treatment plants—anti-seepage isn’t optional. It’s a must. These places handle all sorts of bad stuff: toxic chemicals, rotting waste, contaminated water. A good anti-seepage material blocks those toxins from seeping into groundwater or nearby soil, keeping ecosystems and communities safe. Even highways, railways, tunnels—they can’t skip anti-seepage either. Moisture building up in roadbeds softens the soil, leading to potholes or even road collapses. In tunnels, water leaks can wreck electrical systems and make surfaces slippery, putting travelers at risk. In all these cases, picking a reliable anti-seepage material isn’t just smart—it’s necessary. hdpe black smooth geomembrane delivers strong, steady leak-proofing, and it works in so many different spots. That’s why it fits modern engineering’s core anti-seepage needs so well.

Key Characteristics of hdpe black smooth geomembrane

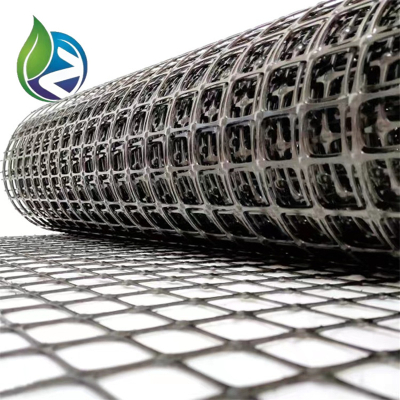

hdpe black smooth geomembrane is made from high-density polyethylene, processed through extrusion and calendering. These are simple steps, but they make a material that’s tough as nails—seriously, this stuff doesn’t break easy. Its unique makeup and design give it traits that are hard to beat for engineering anti-seepage. First off, it has an extremely low water permeability rate—we’re talking almost zero. Water molecules can’t get through, so leaks are basically a non-issue. You won’t find many materials that block water this well. The smooth surface is another big plus. It cuts down on friction with other materials, like soil or gravel, which makes installation way easier. No one wants to fight with a material that sticks or bunches up when you’re laying it. Plus, the smooth surface doesn’t trap debris—so you don’t have to worry about leaves, dirt, or rocks piling up and causing damage later. Another key feature is its mechanical strength. It resists stretching, tearing, and punctures—and that matters a lot on construction sites, where heavy gear, sharp tools, and rough ground are everywhere. It can handle being laid down, covered up, and used daily without breaking or tearing. What’s more, hdpe black smooth geomembrane holds up against chemicals. Acids, alkalis, salts—none of these bother it. It also works in extreme weather: blistering heat, freezing cold, humid areas. And it lasts—decades, usually. That means you won’t have to replace it every few years, which saves time, money, and the hassle of maintenance. For engineering teams, that’s a huge win—less downtime, fewer repairs, and more confidence the project will hold up long-term.

Adaptability of hdpe black smooth geomembrane in Diverse Engineering Scenarios

What makes hdpe black smooth geomembrane so popular, more than anything, is how adaptable it is. It doesn’t matter if the project’s big or small, in a dry desert or a wet coastal area—this material works. Let’s start with water conservancy. It’s commonly used for lining reservoir bottoms, canal walls, and river embankments. In reservoirs, it keeps water from seeping into the soil below, so the reservoir stays full even during dry seasons. We’ve seen farms avoid water shortages just because they used this for their irrigation canals. For canals, it cuts down on water loss as the water moves, which is crucial for irrigation or drinking water supply. On river embankments, it adds a layer of protection against erosion, making the structure more stable and less likely to collapse during floods. For environmental projects, especially landfills, hdpe black smooth geomembrane is a must-have. Landfills make leachate—that toxic water that forms when waste decomposes.

This material acts as a barrier, keeping that leachate from seeping into groundwater or messing up the soil. It’s also used in sewage treatment plants to line tanks and ponds, stopping untreated water from getting into the environment. In infrastructure, like highways and railways, it’s used to waterproof roadbeds and tunnels. Groundwater seepage softens roadbeds, leading to cracks or potholes in highways. In tunnels, moisture can wreck concrete and electrical systems. This geomembrane blocks that seepage, keeping the structure strong and safe for travel. Even in more specialized projects—artificial lakes, fish ponds, chemical storage tanks—it performs. We’ve used it for small backyard fish ponds and huge industrial storage tanks alike, and it holds up every time. Artificial lakes need to hold water without leaking; fish ponds need a clean, stable spot for aquatic life; chemical storage tanks need a barrier that can handle corrosive stuff. hdpe black smooth geomembrane checks all these boxes, adapting to each project’s unique needs without missing a beat.

Installation and Maintenance Essentials for Long-Term Performance

If you want to get the most out of hdpe black smooth geomembrane, proper installation and regular upkeep aren’t up for debate. You can have the best material in the world, but if you install it wrong, it won’t work like it should. Let’s start with installation. First, prep the foundation. It needs to be clean and level—no rocks, branches, glass shards, or sharp junk. Even a small stone can poke a hole in the membrane once it’s laid down—we’ve seen that happen on job sites before. Small oversight, big headache later. So take the time to clear everything out. Next, lay the geomembrane like the project design says. Keep the surface flat and wrinkle-free—wrinkles make weak spots where leaks might pop up. Make sure adjacent sheets overlap by the required width, usually a few inches, to get a tight seal. Most of the time, you join geomembrane with hot-melt welding. This is a key step—if the welds are weak, the whole system fails. You have to check each weld carefully, using tools to test for leaks. Don’t rush this part; take the time to make sure every seam is strong and airtight. Once installation’s done, do a water-filled test or air-tightness check. For ponds or tanks, fill ’em up with water and let sit a few days—if the water level doesn’t drop, you’re good. For other structures, use air pressure to test for leaks. Now, maintenance. It’s not complicated, but it’s important. Inspect the membrane regularly—at least a few times a year, or after bad weather like storms or floods. Look for cracks, punctures, or signs of wear. If you find damage, fix it right away with patch kits made for hdpe geomembrane. Don’t leave heavy equipment or sharp objects on the membrane for long. Even something simple, like a pile of construction materials, can cause damage over time. Also, keep strong chemicals away—yeah, the material’s chemical-resistant, but sitting in highly concentrated stuff for too long can wear it down. Follow these steps, and hdpe black smooth geomembrane will keep performing its best for decades, keeping your project safe and making it last longer.

The Future Trend of Anti-Seepage Materials in Engineering Industry

The global engineering industry’s growing fast, and these days, there’s more focus than ever on protecting the environment and saving resources. That means demand for high-performance anti-seepage materials will keep going up—and hdpe black smooth geomembrane is ready to lead the way. So what’s next for this material? For one thing, it’ll get even better. Material science is advancing, so we’ll see better heat resistance, more flexibility in cold weather, and stronger aging resistance. This will let it work in more extreme spots—like deserts with scorching temps or polar regions that freeze solid. Production processes will get more eco-friendly too. Manufacturers are already moving to energy-efficient methods, and this trend will keep going. We’ll see less waste, lower carbon emissions, and more recycled materials in production—all matching global sustainability goals. Another big change will be smarter installation and maintenance. As construction tech gets better, we’ll see tools like drones used to inspect big areas of geomembrane, making it easier to spot damage fast. They might even put AI-powered sensors in the membrane to monitor performance in real time, alerting teams to problems before they get big. Plus, prefabricated geomembrane sheets will become more common, cutting down installation time and reducing human error. All these changes will make hdpe black smooth geomembrane even more reliable, efficient, and cost-effective. It’s safe to say, in future engineering projects, this material will be an even more important “safety shield”—helping build better, safer, and more sustainable structures all over the world.

All in all, as engineering safety and environmental standards get tighter, geomembrane has become a material you just can’t do without. hdpe black smooth geomembrane, with its strong performance, flexibility, and long life, has earned the trust of engineering teams everywhere. From water conservancy projects that keep communities supplied with water to environmental facilities that protect ecosystems, from highways that connect cities to specialized tanks that store chemicals safely—this material builds a solid anti-seepage barrier that keeps projects on track. It’s not just some plastic sheet—it’s a solution that actually works for the real problems engineers face every day. With tech advancing and more uses popping up, hdpe black smooth geomembrane will keep delivering value, pushing the engineering industry toward safer, more efficient, and greener development. For anyone working on an engineering project that needs top-tier anti-seepage, this material isn’t just an option—it’s the smart choice that stands the test of time.