Exploring the Relationship Between HDPE Geomembrane Thickness and Service Life

When it comes to selecting substances for anti-seepage projects, HDPE geomembrane is constantly a pinnacle desire for engineers and contractors. It’s durable, stands up to chemicals, and doesn’t let water seep thru easily—perfect for landfills, reservoirs, and wastewater remedy plants. But one query continues popping up: how does hdpe geomembrane thickness have an effect on how lengthy the stuff lasts? This article takes a shut seem at that connection, breaking down the key matters that hyperlink thickness to provider lifestyles and giving sensible pointers for planning projects.

How Thickness Helps With Wear and Tear

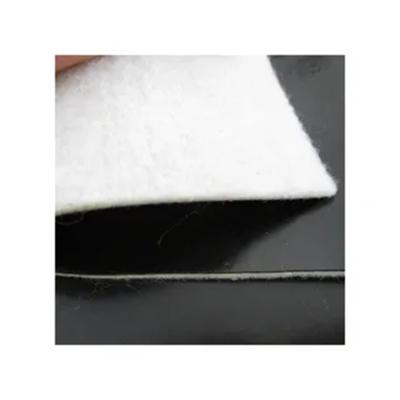

One of the easiest approaches hdpe geomembrane thickness impacts how lengthy it lasts is via put on resistance. Think of it like shoes—thicker soles can take greater steps and scuffs earlier than they put on out. HDPE geomembranes work the identical way.

In busy areas, like development zones the place heavy machines pressure over the membrane, or web sites the place soil shifts a lot, a thicker geomembrane holds up higher towards rubbing and pressure. Thin membranes are satisfactory in low-stress spots, however over time, steady rubbing or weight can make them crack or skinny out. For example, in landfills the place waste receives compacted all the time, a hdpe geomembrane thickness of 1.5mm or greater is normally advocated to cope with the grinding from all that debris.

And it’s no longer just heavy stuff. Thicker HDPE geomembranes additionally deal higher with environmental wear, like when temperatures swing up and down with the seasons. After years of that, skinny membranes can get brittle and tear easy. A larger hdpe geomembrane thickness offers greater fabric to soak up these stresses, so the membrane doesn’t fail as fast.

Thickness and Fighting Off Chemicals & Sunlight

HDPE geomembranes don’t simply take bodily beatings—they additionally have to stand up to chemical substances and UV rays, specifically in out of doors or industrial spots. Here, hdpe geomembrane thickness makes a massive distinction in how lengthy they last.

In initiatives like chemical storage ponds or farm irrigation systems, the membrane comes into contact with fertilizers, pesticides, or industrial fluids. These matters can slowly damage down the fabric over time. A thicker membrane acts like a higher defend towards this. For instance, a 2mm HDPE geomembrane uncovered to vulnerable acids will take way longer to get pinholes than a 0.5mm one, because the chemical substances have to consume thru extra fabric first.

Sunlight is some other sneaky problem. UV rays wreck down HDPE’s shape over time, making it brittle. Thicker membranes have greater fabric to shield the internal layers, so they withstand that growing older better. In sunny areas, selecting a greater hdpe geomembrane thickness (along with UV-stabilized additives) can make the membrane ultimate 10–15 years longer than thinner ones.

Thickness as a Safety Net for Imperfections

No building website is flawlessly smooth, and even small set up flubs can have an effect on how lengthy a geomembrane lasts. That’s the place hdpe geomembrane thickness acts like a security internet for real-world mistakes.

Sharp rocks, developing roots, or bumpy soil below the membrane can create spots with plenty of pressure. A skinny membrane would possibly puncture handy if it’s pressed in opposition to a sharp object, however a thicker one spreads that strain out more, decreasing the hazard of tearing. For example, in landfill liners the place the soil isn’t flawlessly prepped, a hdpe geomembrane thickness of 2mm or greater can take care of small uneven spots except ruining the anti-seepage barrier.

Thickness helps with seams too—the locations where two membrane sheets are joined. Seams are typically the weakest components of the installation. Thicker membranes make more suitable seams due to the fact there’s greater fabric to bond when welding or gluing. That capability fewer seam screw ups over time, which is a frequent cause geomembranes want changing early.

Balancing Thickness with Flexibility and Installation

While thicker HDPE geomembranes really assist them closing longer, there’s a capture with flexibility—and that can mess with their carrier lifestyles if set up isn’t performed right.

A genuinely thick geomembrane (like 3mm or more) is stiff, making it challenging to lay easily over curves or slopes. If you pressure it into place, it may get stretched tight and crack later. On the flip side, a membrane that’s too skinny may stretch too a great deal in the course of installation, weakening its structure. The key is selecting a hdpe geomembrane thickness that matches the site’s shape. For flat, huge tasks like reservoirs, thicker membranes work great. But for bumpy terrain, a medium thickness (1–1.5mm) would possibly be less complicated to set up correctly—and cease up lasting longer due to the fact of it.

Installation strategies count too. Thicker membranes want greater specific welding to make positive they stick—gaps can entice water or debris, which pace up wear. Contractors who’ve labored with distinctive thicknesses recognize to modify their techniques, like the use of greater warmth to weld thicker sheets, to make certain the membrane lasts as lengthy as possible.

Real-World Examples: Thickness and Longevity

Looking at actual initiatives indicates simply how a whole lot hdpe geomembrane thickness impacts provider life. In a 10-year find out about of wastewater remedy plants, the ones the usage of 1.5mm HDPE geomembranes wanted 30% greater repairs and replacements than these the usage of 2mm ones. The thinner ones developed extra leaks round pipes and edges, the place stress is highest.

Another instance is mining operations, the place geomembranes face harsh chemical substances and heavy loads. Mines the usage of 2.5mm HDPE geomembranes lasted 15–20 years on average, whilst 1mm membranes in comparable spots solely lasted 8–12 years. These actual effects again up the notion that a greater hdpe geomembrane thickness capability a longer lifespan, specially in challenging environments.

Picking the Right Thickness for Your Project

So how do you pick the proper hdpe geomembrane thickness to make it final as lengthy as possible? Start by means of searching at the unique dangers your venture faces:

· Environmental stress: If there’s a lot of sunlight, intense temperatures, or contact with chemicals, go for thicker membranes (2mm+).

· Mechanical stress: For heavy loads, plenty of traffic, or transferring soil, use thicknesses of 1.5mm or more.

· Installation conditions: If the terrain is hard or the form is tricky, a medium thickness (1–1.5mm) may be simpler to installation well—and that capacity it’ll closing longer.

It’s additionally clever to assume about long-term costs. Thicker geomembranes fee greater upfront, however they frequently reduce down on protection and substitute expenses. A 1mm membrane may retailer cash at first, however in high-stress areas, it may want to want changing twice as regularly as a 2mm one.

Wrapping Up

The hyperlink between hdpe geomembrane thickness and carrier lifestyles is clear: most of the time, thicker membranes are greater durable, stand up to put on better, and manage real-world issues extra effectively. But it’s now not one-size-fits-all. The satisfactory thickness relies upon on the project’s environment, how it’s installed, and the budget.

By grasp how thickness impacts wear, chemical resistance, and set up quality, contractors and engineers can make higher options to lengthen the geomembrane’s life. That leads to safer, greater within your means anti-seepage systems. Whether you’re working on a small pond or a massive industrial site, retaining hdpe geomembrane thickness in idea as a key element for toughness will assist construct initiatives that stand the check of time.