What is geotextile and what are its functions?

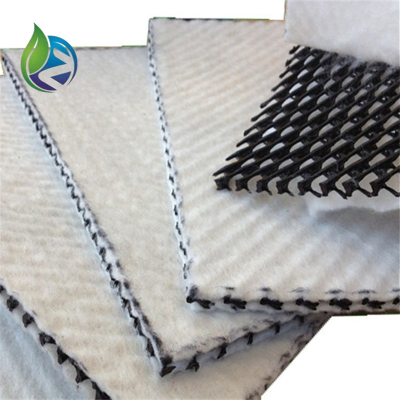

Geotextile is made through combining high-strength fiber bundles with non-woven fabric through a weaving process. The fibers are arranged straight to absolutely utilize the tensile strength of the yarns. A non-woven fabric pad is positioned beneath, and the warp knitting technique is used to wrap and bind them together, ensuring that the fiber bundles and non-woven fabric are consolidated whilst maintaining the non-woven fabric's reverse filtration function and the strength of woven fabric.

Geotextile is a new kind of building material, made from synthetic fibers such as polyester, acrylic, and nylon. According to the manufacturing method, it can be classified into two types: woven geotextile and non-woven geotextile.

Geotextile has a couple of functions including anti-seepage, reverse filtration, drainage, isolation, reinforcement, protection, and sealing. Compared with conventional masonry and concrete substances for anti-seepage, it has the advantages of low investment, simple construction process, brief construction period, good anti-seepage effect, and high high-quality utilization coefficient of channels.

Geotextile is widely used in infrastructure construction, such as reverse filtration for embankments and slopes in water conservancy projects, isolation and anti-seepage for channels, isolation, reverse filtration, and drainage for the foundation of highways, railways, and airport runways, reinforcement and drainage for earth slopes, retaining walls, and road surfaces, soft soil treatment in port engineering, reinforcement and drainage for beach embankments, seaport wharfs, and breakwaters, isolation and anti-seepage for landfill sites, ash dams in thermal electricity plants, and tailing dams in mining plants. It is gradually being applied in more fields.

The features of geotextile include:

1. Drainage: Geotextile is an excellent water-conducting material that can form drainage channels inside the soil to remove excess liquid and gas.

2. Reinforcement: Geotextile can enhance the tensile energy and resistance to deformation of soil, increasing the stability of building buildings and improving soil quality.

3. Protection: It effectively disperses, transmits, or decomposes concentrated stress, stopping soil from being damaged by external forces.

Geotextile has the following characteristics:

1. High strength: Due to the use of plastic fibers, it continues sufficient strength and elongation in both dry and moist conditions.

2. Corrosion resistance: It can resist corrosion in different pH soils and water for a long time.

3. Good permeability: There are areas between the fibers, providing excellent water permeability.

4. Good resistance to microorganisms: It is not broken by microorganisms or insects.

5. Easy to handle: Due to its light weight and flexibility, it is convenient to transport, lay, and install.

6. Complete specifications: The width can attain up to 9 meters, which is the widest product in China. The unit area mass ranges from 100 to one thousand g/m².

There are mainly three series of geotextiles:

1. Needle-punched non-woven geotextile: Available in specifications ranging from one hundred g/m² to 600 g/m², mainly made from polyester or polypropylene short fibers through the needle-punching method. It is by and large used for slope protection of river, sea, and lake embankments, reclamation, flood control and emergency rescue of docks and ship locks, and is an effective way to keep water and soil and prevent piping through reverse filtration.

2. Composite geotextile of needle-punched non-woven fabric and PE film: Available in one cloth and one film, two fabrics and one film, with a maximum width of 4.2 meters. The main uncooked material is polyester short fiber needle-punched non-woven fabric, and it is made by compounding with PE film. It is usually used for anti-seepage and is suitable for railway, highway, tunnel, subway, and airport projects.

3. Composite geotextile of non-woven and woven fabric: There are varieties such as non-woven and polypropylene long fiber woven material composite, and non-woven and plastic woven fabric composite. They are suitable for foundation reinforcement and initiatives that require adjustment of the permeability coefficient.

Application fields

(1) As reinforcement in backfill for retaining walls or for anchoring retaining wall panels. For establishing wrapped retaining walls or abutments.

(2) To reinforce bendy pavements, repair cracks on roads, and prevent reflective cracks on pavements.

(3) To increase the steadiness of gravel slopes and reinforced soil, prevent soil erosion and frost damage to soil at low temperatures.

(4) As a separation layer between ballast and subgrade, or between subgrade and smooth subgrade.

(5) As a separation layer between artificial fill, rockfill or material yards and the foundation, or between different permafrost layers. For filtration and reinforcement.

(6) As a filter layer on the preliminary upstream face of ash dams or tailing dams, or in the drainage system of backfill for retaining walls.

(7) As a filter layer around drainage pipes or round gravel drainage channels.

(8) As a filter layer for water wells, relief wells or inclined pressure pipes in water conservancy projects.

(9) As a geotextile separation layer between ballast, railway ballast, artificial rockfill and the foundation.

(10) For vertical or horizontal drainage inner earth dams, and for dissipating pore water pressure when buried in the soil.

(11) For drainage behind anti-seepage geotextiles or under concrete going through in earth dams or embankments.

(12) For draining seepage around tunnels, reducing the external water stress on linings and seepage around various structures.

(13) For drainage in artificial fill foundations of sports activities fields.

(14) To strengthen weak subgrades in highway, railway, embankment, earth-rock dam, airport, sports subject and other projects.

Installation of Geotextiles

Geotextile rolls should be protected from harm before installation and unrolling. They should be saved on a flat, non-waterlogged surface, with no more than four rolls stacked and the identification tags visible. Geotextile rolls must be protected with opaque materials to prevent UV aging. During storage, keep labels and documentation intact. During transportation (including from storage to the work site), geotextile rolls ought to be protected from damage.

Basic requirements for geotextile laying:

1. Joints must intersect with slope lines; at the slope foot or where stress may exist, the distance between horizontal joints must be greater than 1.5m.

2. On the slope, anchor one end of the geotextile, then lay the roll down the slope to ensure the geotextile remains taut.

3. All geotextiles must be held down with sandbags, which will be used during laying and retained until the next layer of material is laid.

Geotextile laying process requirements:

1. Base inspection: Check if the base is flat and solid. If there are foreign objects, they should be properly dealt with.

2. Trial laying: Determine the size of the geotextile based on the site conditions, cut it and lay it for trial. The cutting size should be accurate.

3. Check if the laying width is appropriate, and the joint should be flat and neither too tight nor too loose.

4. Positioning: Use a hot air gun to bond the overlapping parts of two geotextiles. The spacing of the bonding points should be appropriate.

5. When sewing the overlapping parts, the sewing line should be straight and the stitches should be uniform.

6. After sewing, check if the geotextile is laid flat and if there are any defects.

7. If there are any non-compliant phenomena, they should be repaired in a timely manner.

Self-inspection and repair:

a. All geotextile sheets and seams must be inspected. Defective geotextile sheets and seams must be clearly marked on the geotextile and repaired.

b. Worn geotextile can be repaired by laying and heat-connecting small geotextile sheets. The small geotextile sheets should be at least 200mm longer than the defective edge in all directions. The heat connection must be strictly controlled to ensure that the geotextile patch and the geotextile are closely bonded and do not cause damage to the geotextile.

c. Before the end of each day's laying, visually inspect the surface of all laid geotextile to determine that all damaged areas have been marked and repaired immediately. Ensure that there are no foreign substances that may cause damage to the laying surface, such as fine needles, small iron nails, etc.

d. When repairing geotextile damage, the following technical requirements should be met:

e. The patch material used to patch holes or cracks should be consistent with the geotextile.

f. The patch should extend at least 30cm beyond the damaged geotextile area.

g. At the bottom of the landfill, if the geotextile crack exceeds 10% of the width of the roll, the damaged part should be removed, and then the two geotextiles should be connected; if on the slope, if the crack exceeds 10% of the width of the roll, the entire roll of geotextile should be removed and replaced with a new roll.

h. The work shoes worn by the construction personnel and the construction machinery used should not damage the geotextile. Construction personnel should not do anything that may harm the geotextile on the laid geotextile, such as smoking or using sharp tools to poke the geotextile.

i. To ensure the safety of the geotextile material, the packaging film should be opened before laying the geotextile, that is, lay one roll and open one roll. And inspect the appearance quality.

j. Special mention: Geotextile should be inspected and signed for immediately after arriving at the site.

The "Geotextile Construction and Acceptance Procedures" of the company should be strictly implemented.

Other Information:

The good air permeability and water permeability of geotextiles allow water to bypass through while effectively preserving sand and soil.

Geotextiles have excellent water conduction properties, creating drainage channels within the soil shape to expel excess liquids and gases.

They effectively disperse, switch or dissipate concentrated stresses, preventing soil from being damaged through external forces.

They prevent the mixing of upper and decrease layers of sand, soil and concrete.

High water permeability - maintaining good water permeability under the stress of soil and water.

Corrosion resistance - made from chemical fibers such as polypropylene or polyester, resistant to acids and alkalis, not subject to insect damage, and resistant to oxidation.

Simple construction - mild weight, easy to use, and simple to install.