Why choose glass fiber geogrid

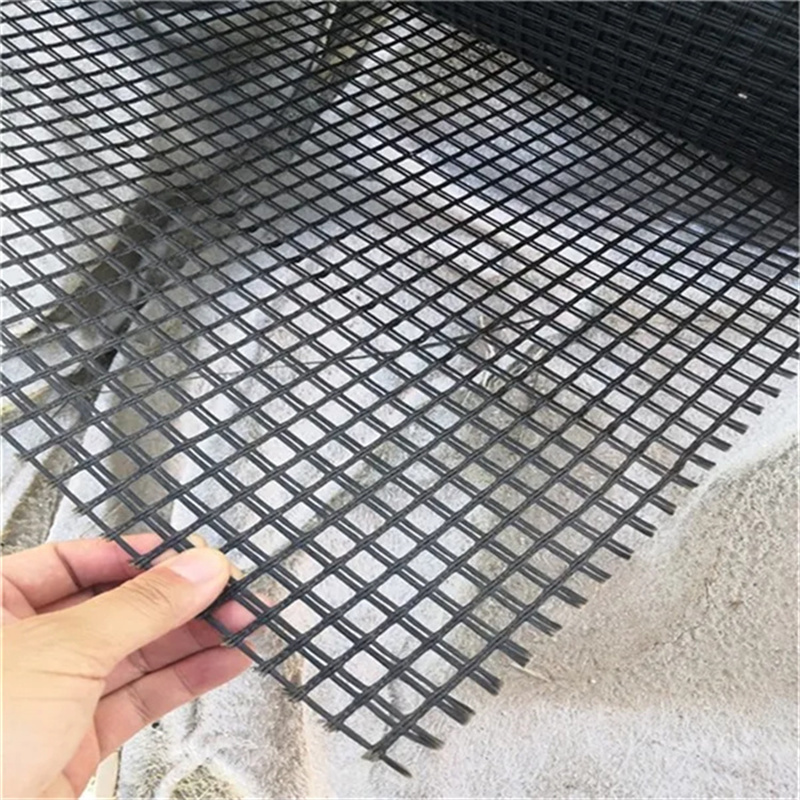

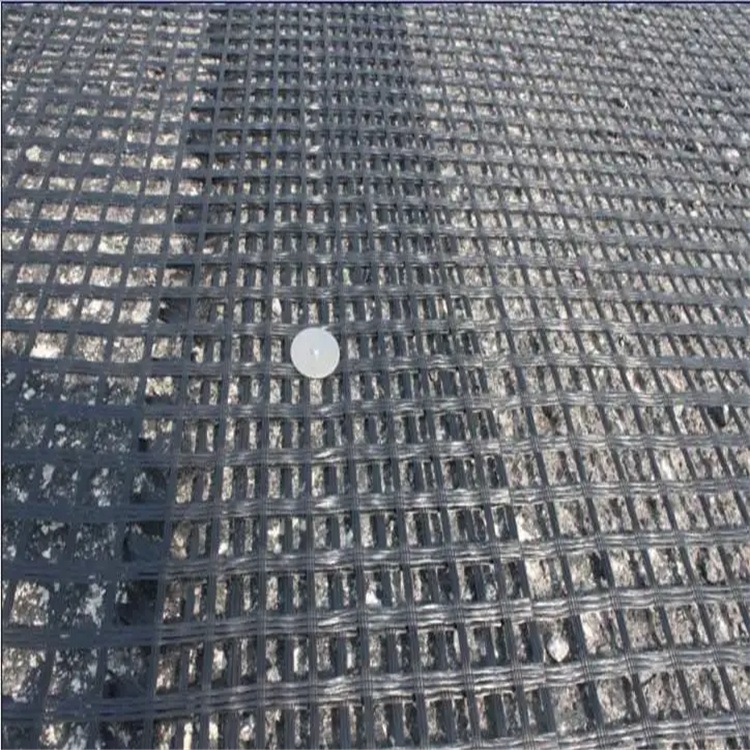

Glass fiber grating is a mesh structure material made of glass fiber, using a certain weaving process. In order to protect glass fiber and improve the overall performance, it is a geocomposite material formed by a special coating process.

In modern construction and civil engineering, ground reinforcement is key to structural durability. When it comes to stabilizing roads, embankments, and foundations, one question often arises: why choose glass fiber geogrid over other materials? The answer lies in its superior strength, stability, and long-term performance.

What Is Glass Fiber Geogrid?

Glass fiber geogrid is a high-performance, grid-like reinforcement product made from fiberglass yarns coated with a polymer. It’s used primarily for soil stabilization, base reinforcement, and pavement overlays. If you're wondering why choose glass fiber geogrid, understanding its composition and function is the first step.

Why Choose Glass Fiber Geogrid? – Top Benefits

Let’s dive into the core reasons why choosing glass fiber geogrid is a smart decision for infrastructure and geotechnical projects.

1. Exceptional Tensile Strength

One of the key reasons why choose glass fiber geogrid is its superior tensile strength. Unlike traditional materials, glass fiber geogrids maintain strength under high loads and prevent deformation in both longitudinal and transverse directions.

2. Improved Load Distribution

Glass fiber geogrids distribute loads more evenly across the soil surface, reducing pressure on subgrades. This is a major reason why choose glass fiber geogrid for roadbeds, highways, and heavily loaded structures.

3. Superior Resistance to Creep

Compared to polymer-based geogrids, fiberglass has a significantly lower creep tendency. For long-term stability in high-load areas, this is a critical factor in why choose glass fiber geogrid over other options.

4. Thermal and Chemical Stability

Another compelling reason why choose glass fiber geogrid is its resistance to extreme temperatures, moisture, and chemical attack. This makes it ideal for environments with fluctuating conditions or exposure to aggressive substances.

5. Enhanced Crack Resistance in Pavements

When used in asphalt overlays, glass fiber geogrid significantly reduces reflective cracking. This not only prolongs pavement life but also reduces maintenance costs—yet another reason why choose glass fiber geogrid in road construction.

6. Easy Installation & Lightweight Design

Glass fiber geogrids are lightweight and easy to handle, which simplifies installation and reduces labor costs. This is a practical reason why choose glass fiber geogrid for time-sensitive or large-scale projects.

7. Cost-Effectiveness Over Time

Although the initial cost may be slightly higher than some alternatives, its durability and minimal maintenance needs make it cost-effective in the long run. This is a financial reason why choose glass fiber geogrid for large infrastructure projects.

Where to Use Glass Fiber Geogrid?

Asphalt overlays

Reinforced soil embankments

Retaining walls

Airport runways

Parking lots

Railway ballast layers

If you’re still asking why choose glass fiber geogrid, just look at its performance in these applications—it consistently outperforms traditional solutions.

Final Thoughts

So, why choose glass fiber geogrid? The answer is clear: unmatched strength, low maintenance, thermal resilience, and proven cost-efficiency make it the top choice for engineers and contractors alike. If long-term soil reinforcement and project sustainability matter to you, glass fiber geogrid is the way to go.