The Role of Geotextiles

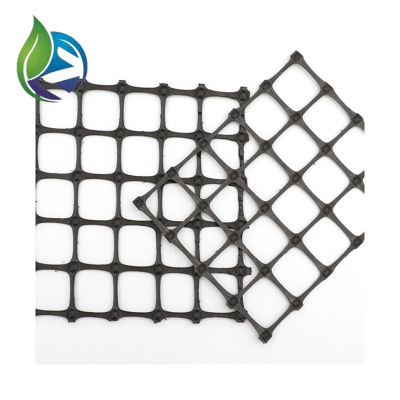

Product Definition

Geotextiles are permeable geosynthetic materials used in civil and environmental engineering to enhance soil performance. Installed in contact with soil, they provide separation, filtration, drainage, reinforcement, and protection, improving structural stability, service life, and cost efficiency of infrastructure projects.

Technical Parameters and Specifications

Geotextile performance is defined by mechanical, hydraulic, and durability parameters. Selection must comply with project design standards and site conditions.

Raw materials: Polypropylene (PP), Polyester (PET)

Manufacturing types: Nonwoven needle-punched, woven slit film, woven monofilament

Mass per unit area: 100–800 g/m²

Tensile strength: 8–120 kN/m (MD/CD)

Elongation at break: 10%–80%

CBR puncture resistance: 1.5–12 kN

Permittivity: 0.1–1.5 s⁻¹

Apparent opening size (AOS): 0.075–0.6 mm

UV resistance: ≥70% retained strength after 500 hours

Structure and Material Composition

Geotextiles are engineered composite fabrics designed for interaction with soil and aggregates.

Fiber layer: Continuous or staple synthetic fibers for tensile performance

Bonding method: Needle-punching, weaving, or thermal bonding

Pore structure: Controlled voids enabling water flow while retaining soil particles

Surface characteristics: Smooth or textured depending on friction requirements

Manufacturing Process

Engineering Production Steps

Polymer granule melting and extrusion into fibers or tapes

Fiber orientation and web formation

Mechanical bonding via needle-punching or weaving looms

Thermal stabilization and surface treatment

Roll cutting, inspection, and packaging

Key equipment: Extruders, carding machines, needle looms, weaving looms, heat-setting ovens, tensile testing systems.

Process control focus: Fiber uniformity, pore size consistency, tensile balance, and long-term durability.

Industry Comparison

| Material | Primary Function | Permeability | Mechanical Strength | Service Life |

|---|---|---|---|---|

| Geotextile | Separation, filtration, reinforcement | High | Medium–High | 25–50 years |

| Geomembrane | Impermeable barrier | None | Medium | 20–40 years |

| Gravel filter layer | Drainage | High | Low | Variable |

| Concrete layer | Structural support | Low | Very High | 30–60 years |

Application Scenarios

The role of geotextiles spans multiple infrastructure and environmental projects.

Roads and highways: Subgrade separation and reinforcement

Railways: Ballast stabilization and drainage control

Landfills: Filtration and protection layers

Water projects: Riverbank protection and drainage systems

EPC contractors: Performance-based ground improvement solutions

Core Pain Points and Engineering Solutions

Soil contamination between layers: Use separation-grade geotextiles

Insufficient drainage: Select high-permittivity nonwoven fabrics

Subgrade deformation: Apply high-tensile woven geotextiles

Premature material failure: Specify UV- and chemical-resistant polymers

Risk Warnings and Mitigation

Incorrect AOS selection may cause clogging or soil loss

Low UV resistance can lead to strength degradation during installation

Improper overlap or anchoring reduces performance

Non-certified materials increase long-term failure risk

Procurement and Selection Guide

Define project function: separation, filtration, or reinforcement

Analyze soil gradation and hydraulic conditions

Determine required tensile and puncture strength

Specify mass per unit area and AOS

Verify compliance with ASTM / EN standards

Review manufacturer quality control documentation

Plan installation method and site logistics

Engineering Case Example

In a highway embankment project with soft clay subgrade, a 400 g/m² nonwoven geotextile was installed between the subgrade and crushed stone layer. The solution improved load distribution, prevented aggregate intrusion, and enhanced drainage. Post-installation monitoring showed reduced settlement and extended pavement service life.

FAQ

What is the primary role of geotextiles? Soil separation, filtration, drainage, reinforcement, and protection.

Woven or nonwoven? Depends on tensile and filtration requirements.

Can geotextiles replace gravel layers? In many drainage and separation applications, yes.

What standards apply? ASTM, EN, ISO geosynthetics standards.

Are geotextiles chemically resistant? PP and PET offer strong resistance to most soils.

What is typical roll width? 4–6 meters.

Do they degrade underground? Properly specified products have long-term durability.

Is UV exposure critical? Yes, during storage and installation.

How is overlap determined? By soil type and load conditions.

Can geotextiles be used underwater? Yes, with appropriate filtration design.

CTA

For detailed technical datasheets, project-specific recommendations, or engineering samples, please submit your inquiry to request specifications or a formal quotation.

E-E-A-T Author Credentials

This article is prepared by a geosynthetics engineering specialist with over 15 years of experience in civil infrastructure materials, including road engineering, hydraulic works, and environmental protection systems, supporting EPC contractors and international procurement teams.